Discharge Pipe and Pressure Tank Connections 5

From

Well

Water System

Relief Valve

Pre-Charged

Tank

20

40

60

80

100

Pressure Gauge

Pressure

Switch

To Household

Water System

Pressure

Switch

Suction Pipe

From Well

Air Volume

Control

Air Volume

Control Tube

Priming Te e

and Plug

Relief Valve

Drive Pipe

To Well

Standard

Tank

20

40

60

80

100

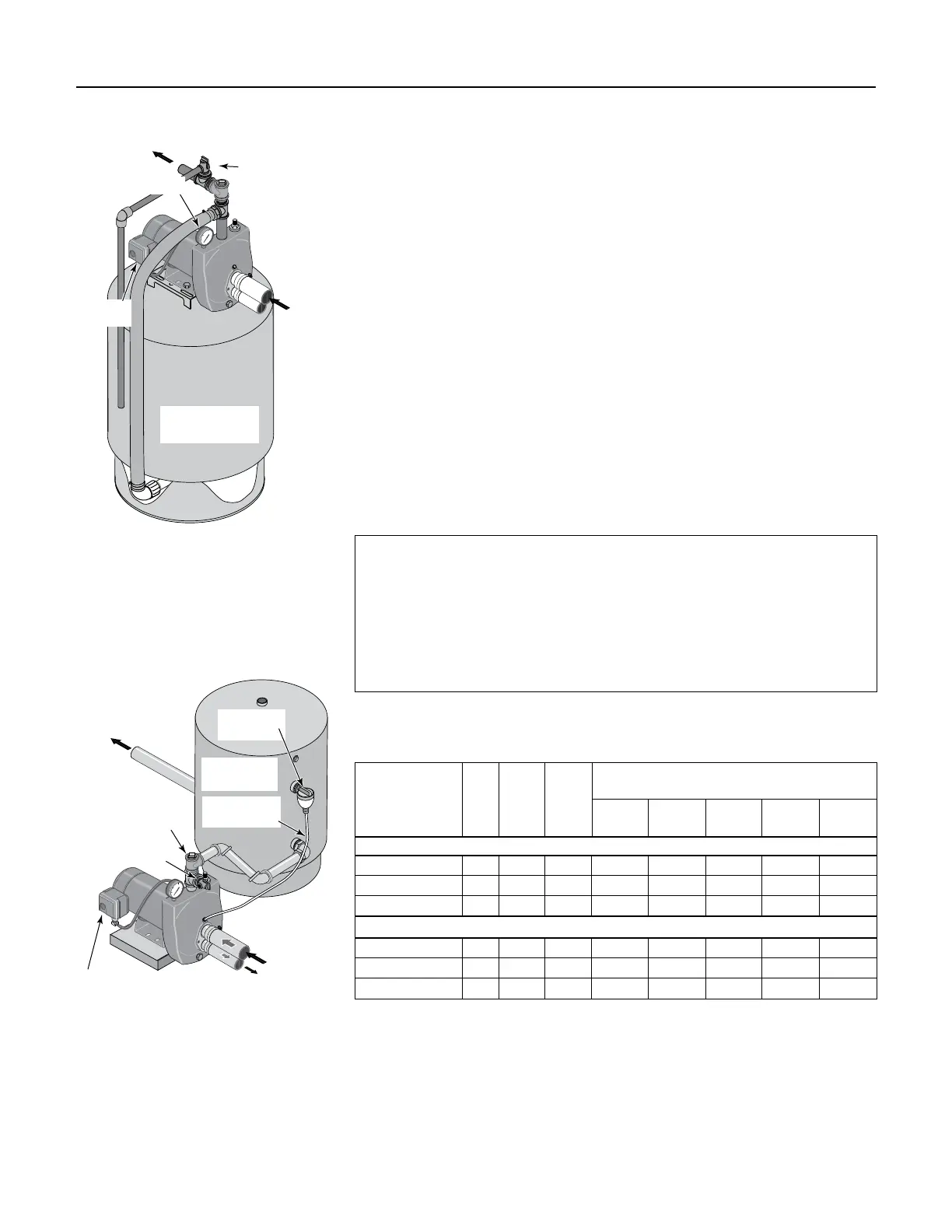

Figure 6: Pre-charged Tank

Connections

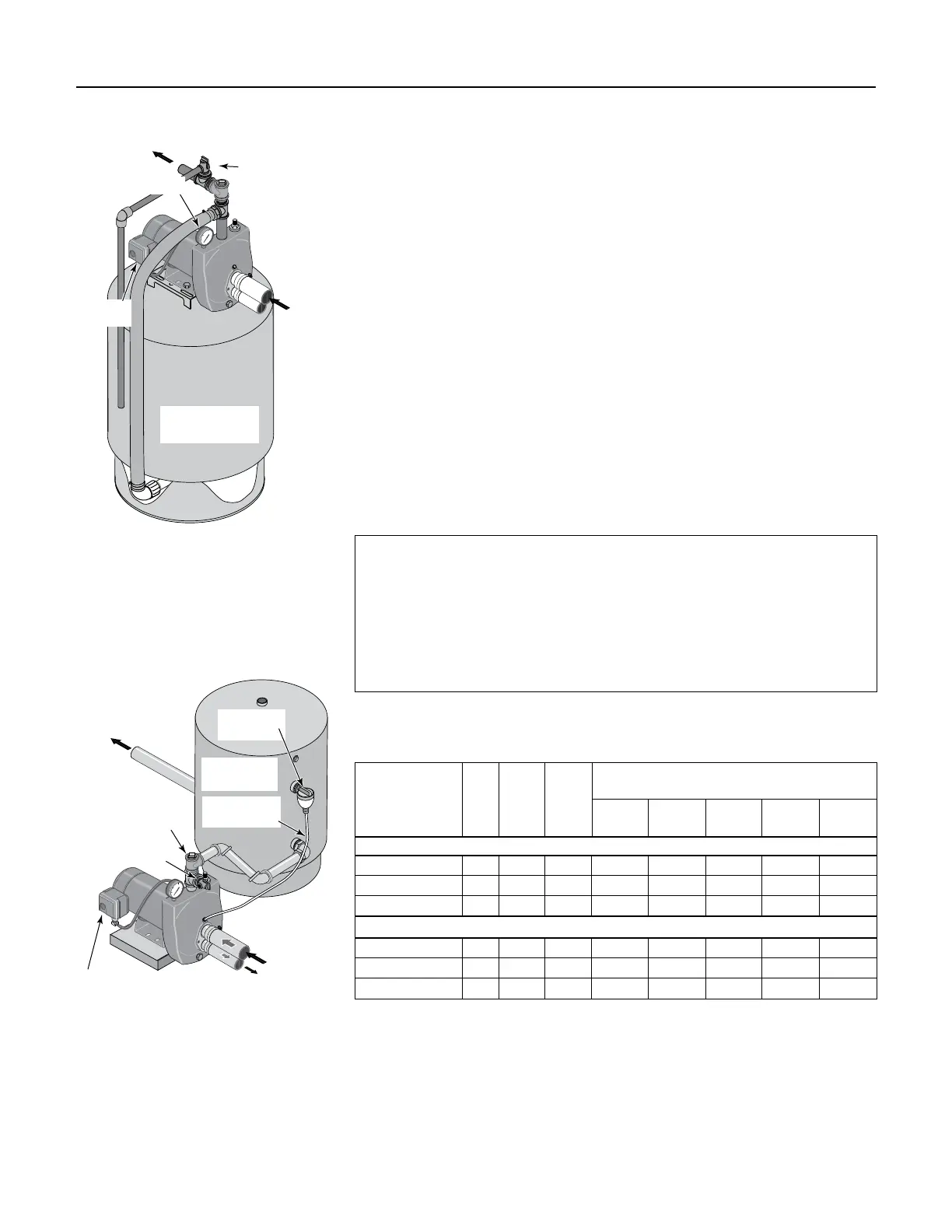

Figure 7: Standard Tank Connections

Table I: Wiring Chart – Recommended Wire and Fuse Sizes

PRE-CHARGE TANK CONNECTION (Figure 6)

If your system uses a pre-charged tank, it should be connected to the pump

as shown in Figure 6. The relief valve must be capable of passing the entire

pump capacity at 100 PSI pressure.

Check the pre-charge of air in the tank with an ordinary tire gauge. the pre-

charge is measured when there is no water pressure in the tank. Disconnect

power to the pump and drain the tank before checking the pre-charge. Your

pump has a 30/50 PSI switch, so the tank pre-charge pressure should be 28

PSI (that is, it should be 2 PSI lower than the cut-in pressure of the pressure

switch.

No AVC is required for a pre-charged tank; the 1/8” NPT AVC port on the

pump body should be plugged.

STANDARD TANK CONNECTION (Figure 7)

If your system uses a standard tank, connect it to the pump as shown in

Figure 7. The relief valve used with a standard tank must be capable of pass-

ing the entire pump capacity at 75 PSI pressure.

Connect the Air Volume Control (AVC) tube to the 1/8” NPT AVC port

on the pump body. Run the tubing from the pump’s AVC port to the AVC

mounted on the tank. See the instructions provided with tank and AVC for

details.

Branch Distance in Feet (Meters);

Max Fuse Wire Size AWG (mm

2

)

Load Rating 0-100 101-200 201-300 301-400 401-500

Model HP Amps Amps (0-30) (31-61) (62-91) (92-122) (123-152)

115Volts:

HNAS-50 1/2 12.2 20 12(3) 10(5.5) 8(8.4) 6(14) 6(14)

HNAS-75 3/4 14.8 20 12(3) 8(8.4) 6(14) 6(14) 4(21)

HNAS-100 1 19.2 25 10(5.5) 8(8.4) 6(14) 4(21) 4(21)

230 Volts:

HNAS-50 1/2 6.1 15 14(2) 14(2) 14(2) 12(3) 12(3)

HNAS-75 3/4 7.4 15 14(2) 14(2) 14(2) 12(3) 10(5.5)

HNAS-100 1 9.6 15 14(2) 14(2) 12(3) 10(5.5) 10(5.5)

Sealing Pipe Joints

Use only PTFE pipe thread sealant tape for making all threaded

connections to the pump itself. Do not use pipe joint compounds on

plastic pumps: they can react with the plastic in pump components.

Make sure that all pipe joints in the suction pipe are air tight as well as

water tight. If the suction pipe can suck air, the pump will not be able to

pull water from the well.

Loading...

Loading...