PART 8: MAINTENANCE AND SERVICE

PB1319 (CAT. NO. 5296 ) —136— 22-01691 (R02/02)

Wheel Cap Nut Torque

At the first 100 miles, have all wheel cap nuts torqued to their speci-

fied value. After that, check wheel cap nuts at least once a week.

Contact the Service Department at your dealership for information on

the proper installation procedure for the wheels on your truck. This is

a job you may not be able to do yourself. You need the right torquing

equipment to do it.

Wheel Bearing Adjustment

For safe, reliable operation and adequate service life, your wheel

bearings must be checked and adjusted properly. The person best

equipped to do this is your authorized dealer’s service mechanic.

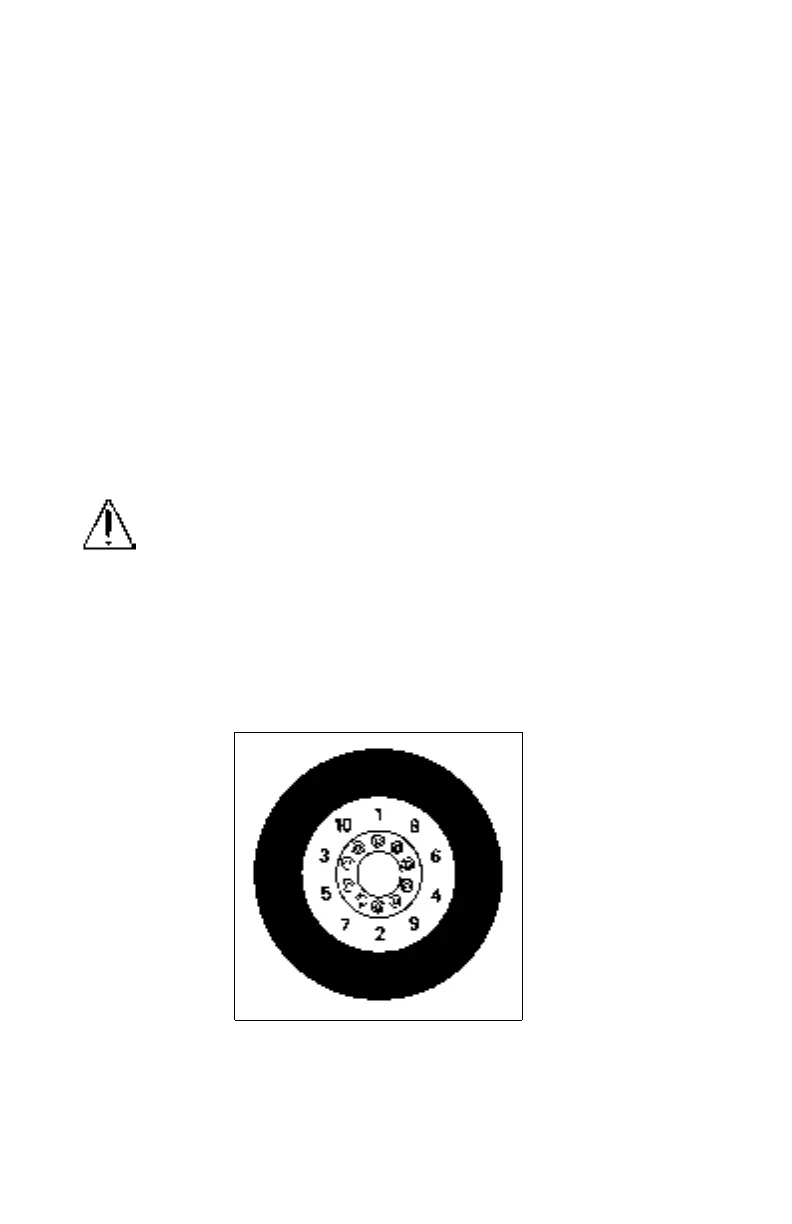

Disc Wheels

To check the torque on disc wheels, follow the crisscross sequence

shown. See the Specifications chart for proper torque specification.

Crisscross Sequence For Disc Wheels

Demountable Rims

To check the torque on demountable rims, follow the crisscross

sequence shown on the next page. See the Specifications chart for

proper torque specification.

WARNING!

•

Grooves in the wheel disc or other damage to the disc

can lead to a serious accident. The disc will be weak-

ened and can eventually come off, maybe causing you

to lose control of your vehicle. Be sure to use the right

components and the right tools.

•

The end of the wheel wrench must be smooth. Burrs

on the end of the wrench can tear grooves in the disc,

especially on aluminum wheels. These grooves may

lead to cracks in the disc, and can cause it to fail.

02950

Loading...

Loading...