PART 8: MAINTENANCE AND SERVICE

PB1319 (CAT. NO. 5296 ) —138— 22-01691 (R02/02)

Your Vehicle’s Air System

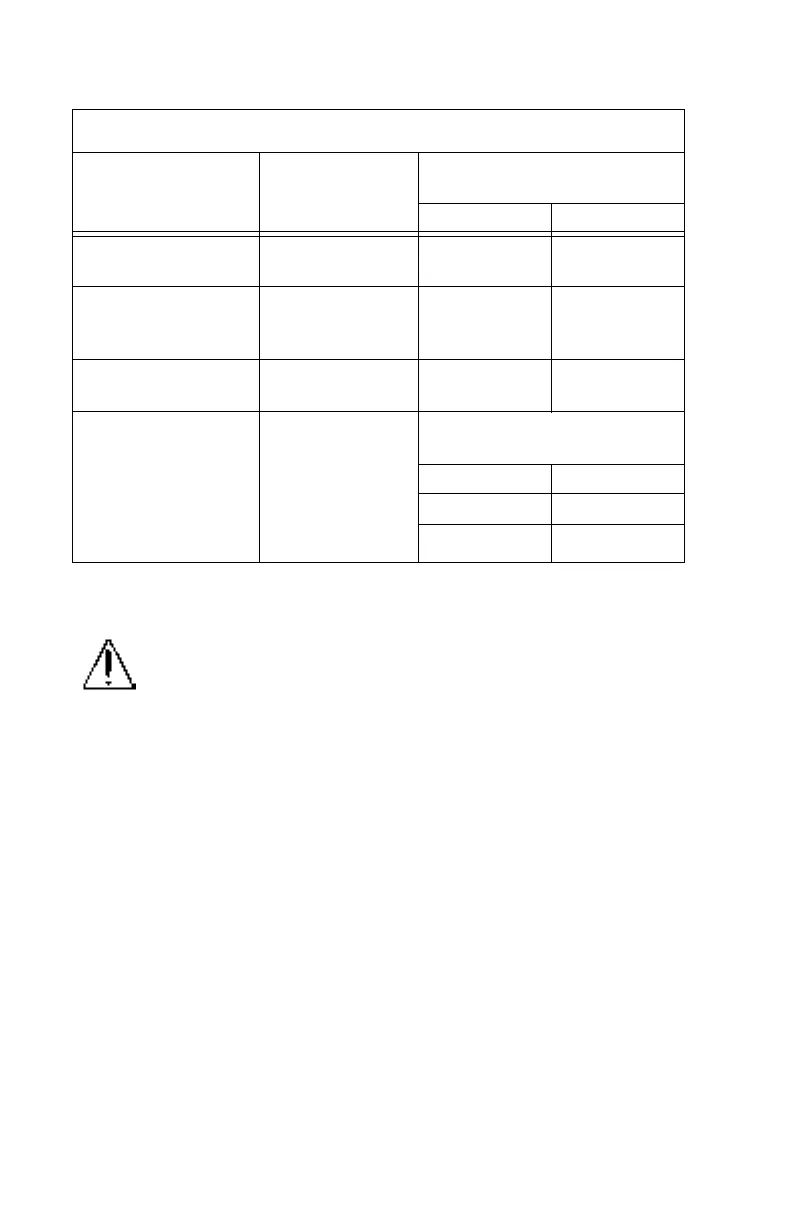

CAP NUT TORQUE SPECIFICATIONS (R12/01)

WHEEL AND NUT

CONFIGURATION

STUD SIZE

TORQUES FOR INNER &

OUTER CAP NUTS

Lb. Ft. N.m

Stud-Piloted Disc

Wheels

3/4”-16 Inner

1 1/8”-16 Outer

450-500 610-680

Heavy Duty Stud-

Piloted Disc Wheels

15/16”-12 Inner

1 5/16”-12

Outer

750-900 1025-1225

PHP-10; Budd Uni-

Mount-10; WHD-8

M22 x 1.5-6H 450-500 610-680

Cast Spoke Wheel

Assembly

1/2” Dia.

5/8” Dia.

3/4” Dia.

Rim Clamp

Nut Torque

80-90 110-120

160-185 220-250

225-245 305-335

WARNING! Prior to the removal of any air system com-

ponent, always block and hold the vehicle by a secure

means other than the vehicle’s own brakes. Depleting

air system pressure may cause vehicle to roll. Keep

hands away from chamber push rods and slack adjust-

ers, they may apply as system pressure drops.

•

After completing any repairs to the air system, always

test for air leaks, and check the brakes for safe opera-

tion before putting the vehicle in service.

•

Never connect or disconnect a hose or line containing

air pressure. It may whip as air escapes. Never remove

a component or pipe plug unless you are certain all

system pressure has been depleted.

•

Never exceed recommended air pressure and always

wear safety glasses when working with air pressure.

Never look into air jets or direct them at anyone.

•

Never attempt to disassemble a component until you

have read and understood recommended procedures.

Some components contain powerful springs and

injury can result if not properly disassembled. Use

only proper tools and observe all precautions pertain-

ing to use of those tools.

Loading...

Loading...