BRAKE ADJUSTMENT PART 8: MAINTENANCE AND SERVICE

– 154 – Y53-6007 (R10/06)

• Watch the rate of air pressure drop registered by the

air gauge. The rate of drop should not be more than 3

psi (21 kPa) per minute.

• If you find excessive leakage, a leakage test should

be made at the air line connections and at all air brake

control units. To perform a leakage test, refer to the

detailed instructions in the Peterbilt Maintenance

Manual, or take your vehicle to an authorized Peterbilt

dealer.

Air Disc Brakes

Have brake pads inspected by a qualified mechanic for

wear at regular intervals according to the

“Preventive

Maintenance Schedule” on page 119. In severe service or

off-highway applications inspect the linings more fre-

quently.

Regularly inspect for pad/rotor wear:

• Park on level ground and chock the wheels.

• Temporarily release the parking brakes.

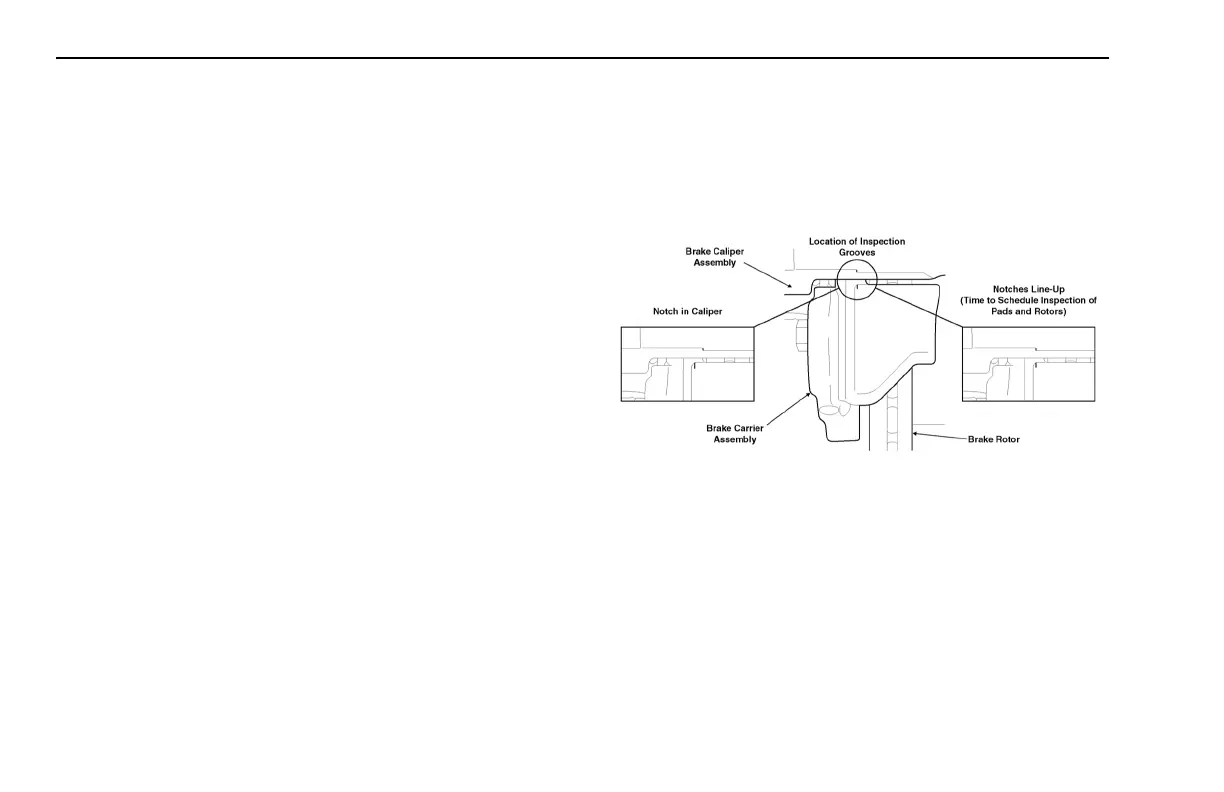

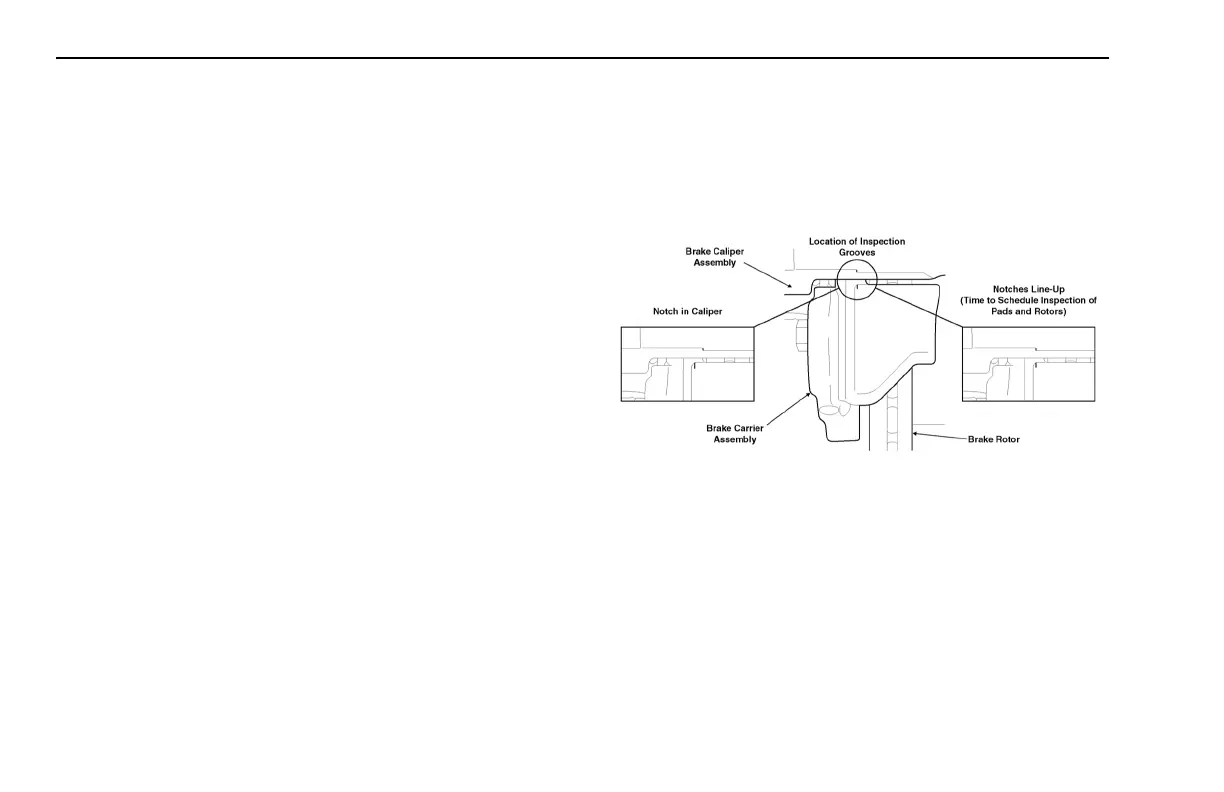

• Compare the relative position of two notches; one

located on the caliper and the other on the carrier.

See the illustration below to determine if the brakes

require a detailed inspection by a qualified mechanic.

• Have a qualified mechanic perform a detailed inspec-

tion if the notches are not found. The pads and rotors

should be measured and compared against the man

-

ufacturers specifications located in the brake manu-

facturer’s service manual.

Regularly inspect caliper for Running Clearance:

• Stop the vehicle on level ground and let the brakes

cool down. Hot brake calipers can burn skin on con

-

tact.

• Chock the wheels.

• Temporarily release the parking brakes.

• Grab the caliper and move it. This movement is Run-

ning Clearance.

Loading...

Loading...