Safet Test Reuirements

All units that are returned for service or repair must

pass the oriinal manufactures safet tests. Safet

testin reuires both Hipot and Ground Continuit

testin.

HI-POT TEST INSTRUCTION

1.Application reuirements

1.1 All mains operated products must pass the Hi-Pot

test as described in this instruction.

1.2 This test must be performed aain after the

covers have been refitted followin the repair

inspection or modification of the product.

2. Test method

2.1 Connectin conditions

2.1.1 The test specified must be applied between the

parallel blade plu of the main scord and all

accessible metal parts of the product.

2.1.2 Before carrin out the test reliable conductive

connections must be ensured and thereafter be

maintained throuhout the test period.

2.1.3 The mains switch(es) must be in the ON

position.

2.2 Test Reuirements

All products should be HiPot and Ground Continuit

tested as follows

Condition

Hi-Pot Test for

products where

the mains input

is 220V AC

Hi-Pot Test for

products where

the mains input

is 110V AC

Ground

Continuit

Test

reuirement

Test

voltae

2820VDC

(2000VAC)

1700VDC

(1200VAC)

Test time 3 seconds 1 seconds

Trip

current

(Tester)

Set at 100uA for

Ma limit

Set at 0.1uA for

Min limit.

5mA

Ramp

time

(Tester)

Set at 2 seconds ʳ

Test current:

25A, AC

Test time: 3

seconds

Resistance

required:

<=0.09+Rohm,

R is the

resistance of

the mains

cord.

91 220CW9

LCD

2.2.1 The minimum test duration for Quality Control

Inspector must be 1 minute.

2.2.2 The test voltage must be maintained within the

specified voltage + 5%.

2.2.3 There must be no breakdown during the test.

2.2.4 The grounding blade or pin of mains plug must

be conducted with accessible metal parts.

3. Equipments and Connection

3.1. Equipments

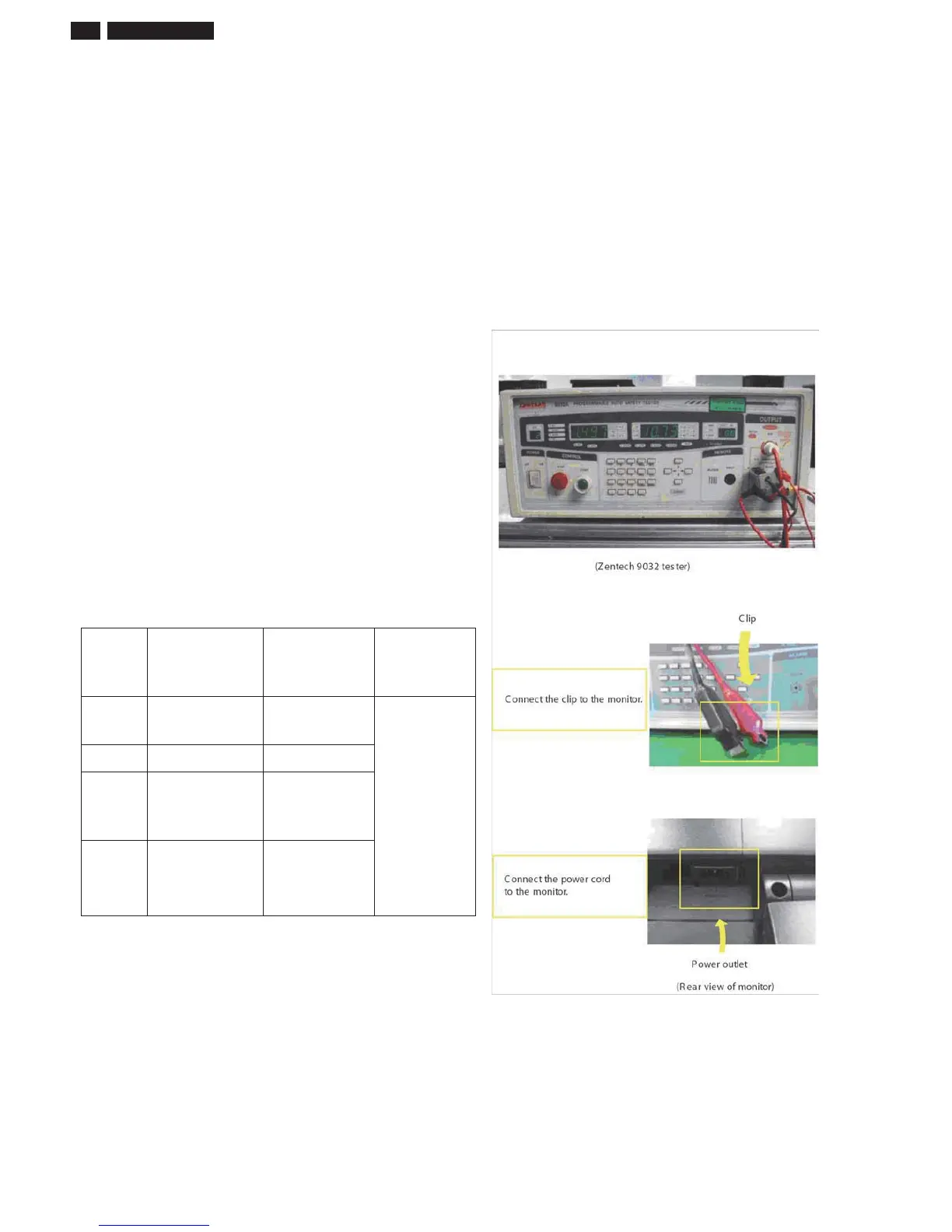

For example :

- Zentech 9032 PROGRAMMABLE AUT O SAFETY

TESTER

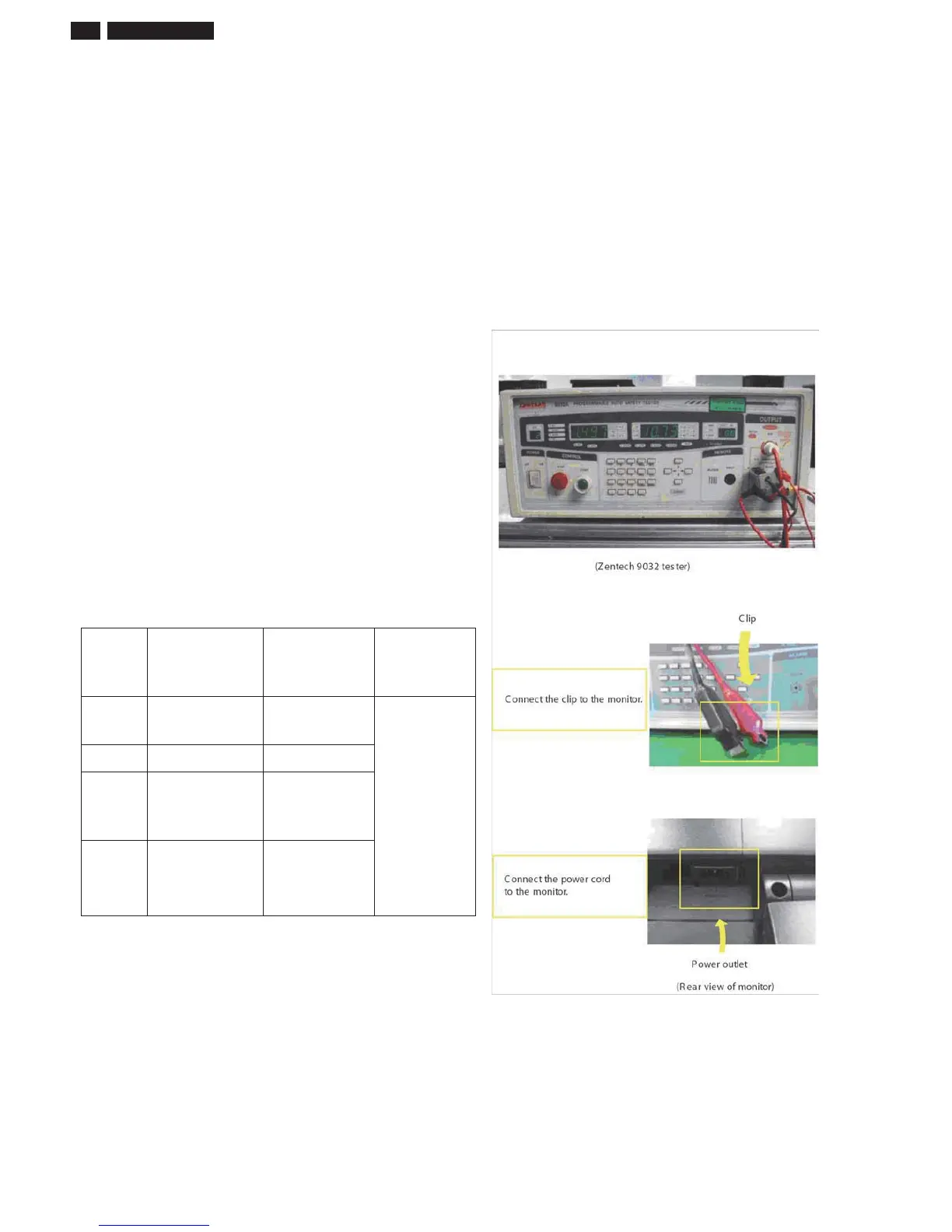

3.2. Connection

* Turn on the power switch of monitor before Hipot

and Ground Continuity testing.

4. Recording

Hipot and Ground Continuity testing records have to

be kept for a period of 10 years.

241%4L3 LCD

Loading...

Loading...