PG.44

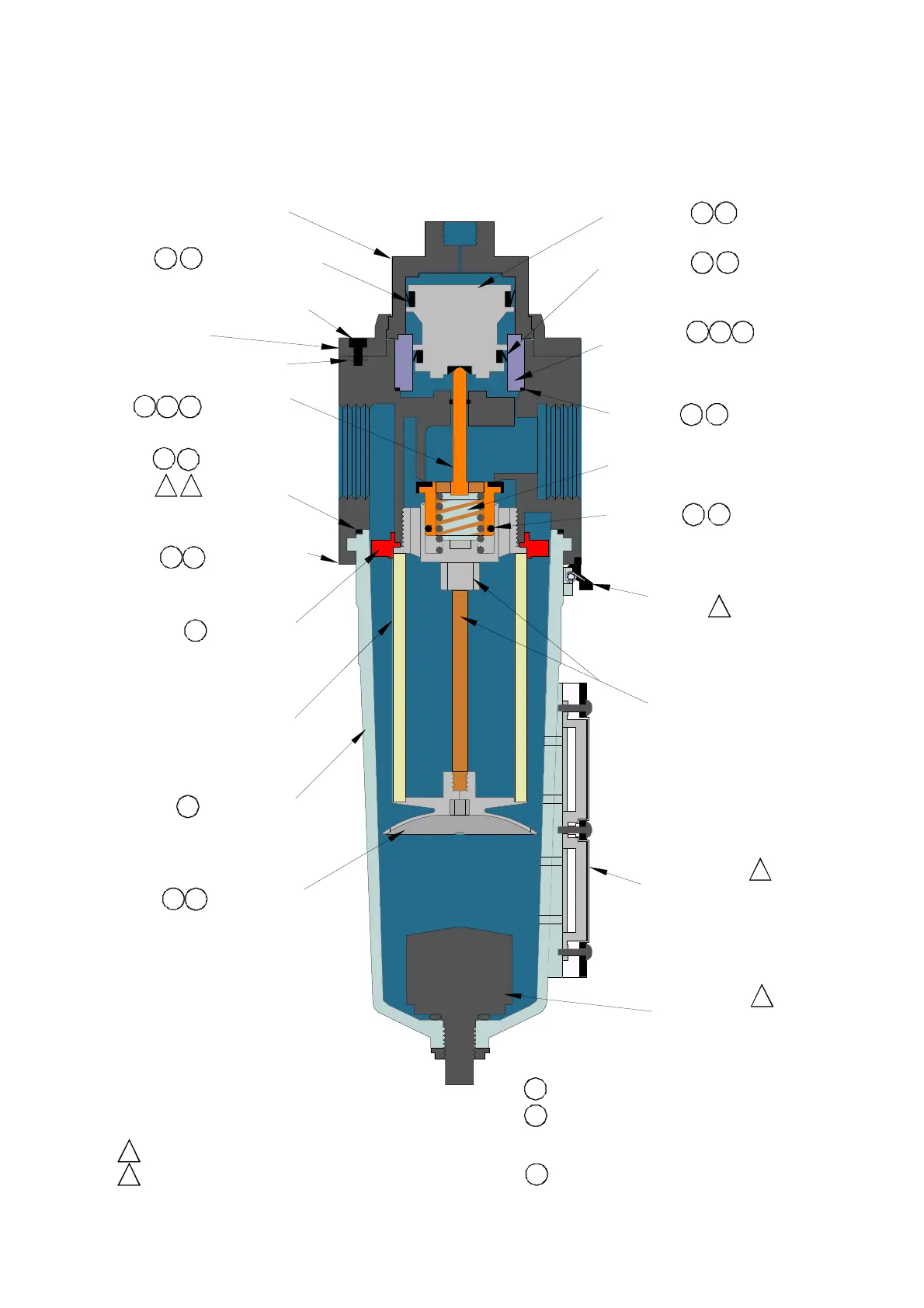

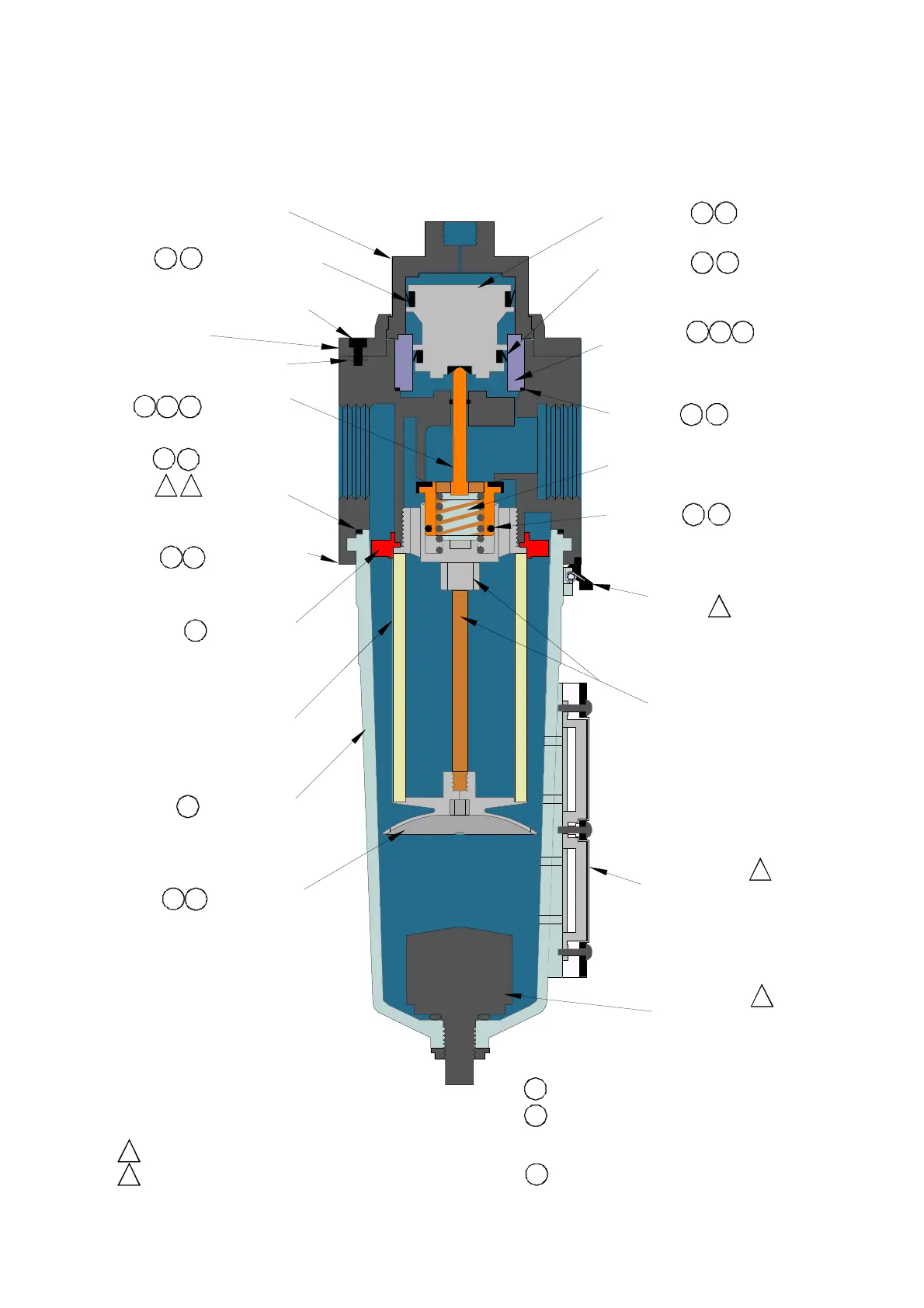

50008-BS1

BOWL SEAL

50008-E01

ELEMENT KIT

50008-AD1

AUTODRAIN KIT

50008-STM

STEM ASSEMBLY

50008-BL1

BOWL LATCH

50008-BK1

BOWL KIT

B

B

E

B

INCLUDED WITH 50008-BK1 BOWL KIT

E

INCLUDED WITH 50008-E01 ELEMENT KIT

50008-DF1

DEFLECTOR

50008-SGK

SIGHT GAUGE KIT

B

30060-001

FILTER/REGULATOR SERVICE INSTRUCTIONS

BONNET

UPPER

PISTON SEAL

10031-001

LOWER

PISTON SEAL

POPPET

ASSEMBLY

30061-001

PISTON

30062-001

SLEEVE

POPPET

SPRING

MAIN BODY

Bowl rotated 90 degrees

for illustration purposes

C

CLEAN WITH A LINT FREE CLOTH

C

LIGHTLY GREASE WITH PROVIDED LUBRICANT

INSPECT FOR NICKS, SCRATCHES, AND SURFACE

IMPERFECTIONS. IF PRESENT, REDUCED SERVICE

LIFE IS PROBABLE AND FUTURE REPLACEMENT

SHOULD BE PLANNED.

C

C

C

C

APPLY LOW STRENGTH

PLASTIC THREADLOCKER

TO NUT

Snap Fit Tab Detent must snap into

groove for proper assembly.

To remove bowl depress tab, turn

& pull bowl down

TORQUE TO 3-5 INCH POUNDS

REFER TO ILLUSTRATION FOR

DISASSEMBLING, SERVICING

AND RE-ASSEMBLY.

MOUNTING SCREWS (4)

TORQUE TO 13-18 INCH POUNDS

50008-BFL

BAFFLE

INSPECT FILTER ELEMENT AND CLEAN BOWL REGULARLY.

A DIRTY FILTER CAN COLLAPSE AND ALLOW

CONTAMINATION OF SYSTEM CONTROLS.

KEEP SPARE ELEMENT ON HAND.

O-RING

O-RING

To remove bowl depress tab,

turn & pull bowl down

BE POSITIVE THAT ALL AIR

PRESSURE IS RELIEVED FROM

SYSTEM AND ALL SAFETY LOCKOUT

REQUIREMENTS HAVE BEEN MET

B

FLANGE

BE SURE THAT ALIGNMENT

NOTCH AROUND SCREW HOLE

IS PROPERLY ALIGNED

Loading...

Loading...