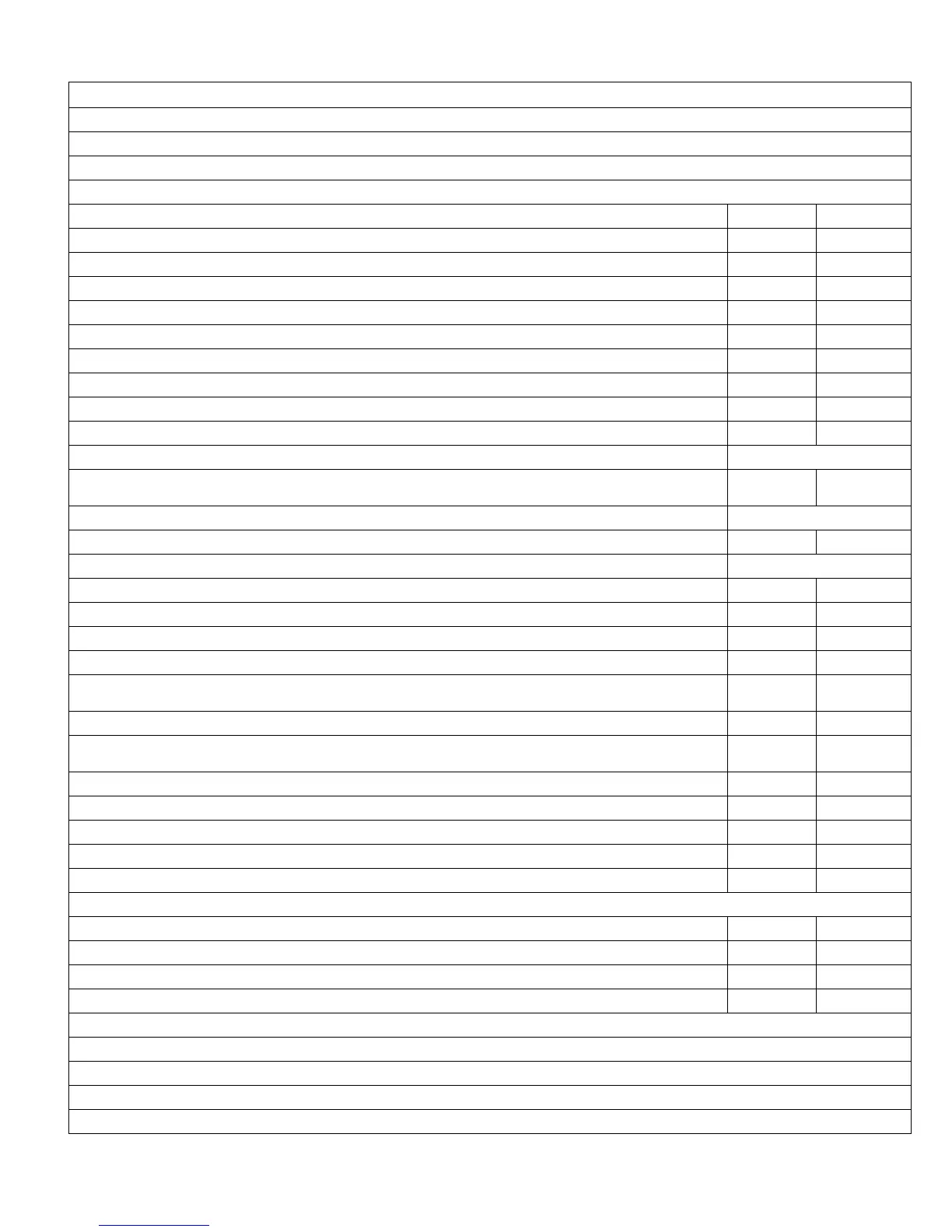

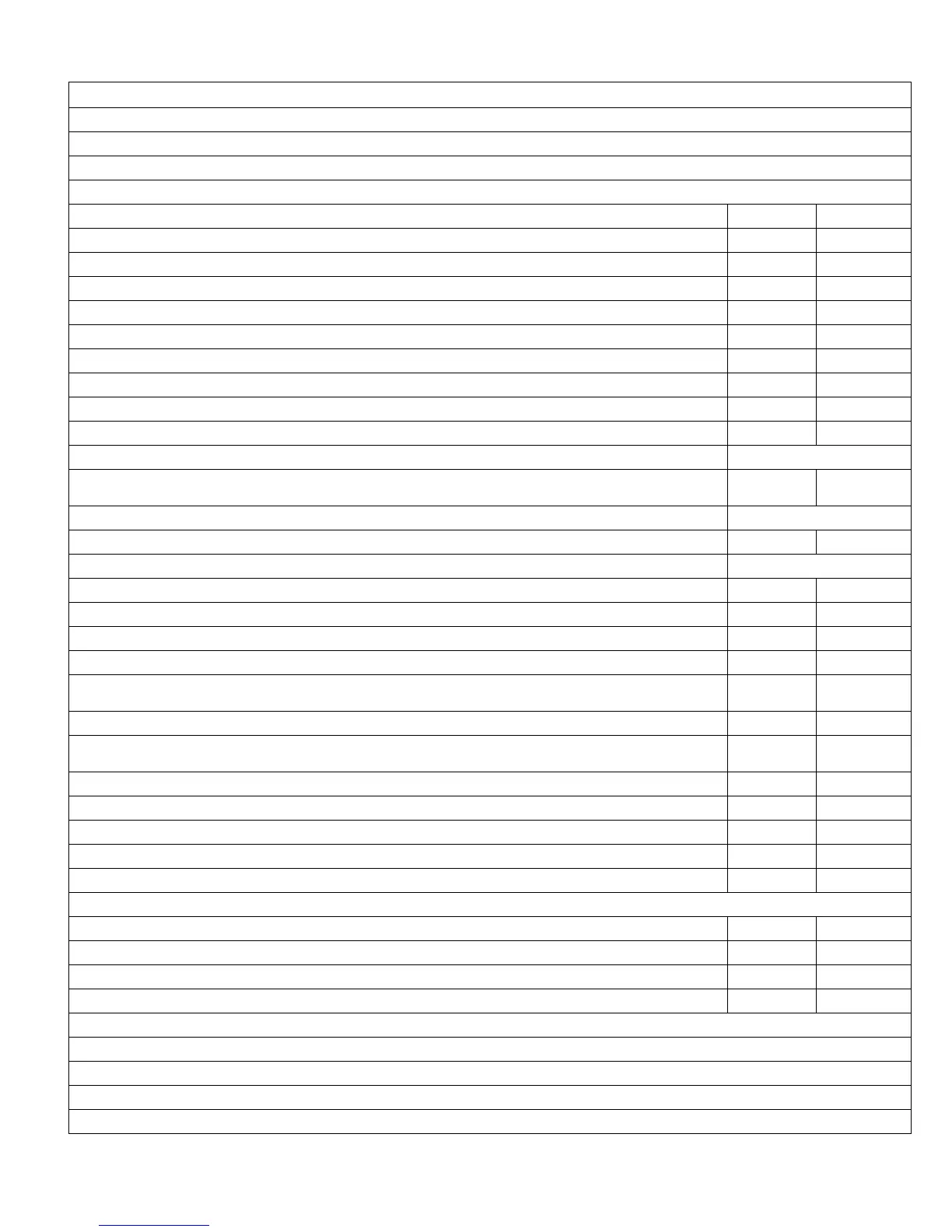

33

Gas connections already installed on site

Chimney connections already installed

Verify all buttons of control panel

RE8-16 = 9A │ RE8-24 = 9 A │ RE8-32=12A

Verify shelve rotation, forward and backwards

Verify ventilator motor rotation; This must turn clock wise.

Verify the connectivity of the wires at the terminal strips and contacts

Verify the door limit switch

Verify sprockets alignment and that the shelves are level

Verify inlet gas pressure when the oven is off: Pressure must be 5 – 14 W.C.

Note the gas line pressure:

Verify inlet gas pressure when the oven is on high fire and all others equipment on the same

pressure regulator are in operation. Pressure must be 5 – 14 W.C.

Note the gas line pressure:

Verify the distributor pressure: 0'' W.C. when the burner is lit on low fire.

Note the distributor pressure:

Verify that the ventilation is installed correctly

Verify air pressure in the system: 16 = 600 CFM │ 24 = 800 CFM │ 32 = 1000 CFM

Verify that the chimney ventilator is installed.

Verify the pressure and the pressure switch

Verify that the burner working well at 400°F and maintain it during 1 hour.

(Verify high and low fire)

Verify that the burner work well at the customer baking temperature.

Verify that there isn't negative pressure while all venting systems in the building are in

operation.

Verify that the baking timer functions correctly

Verify the water flow (

ml/impulsion

) (Steam Option) 16 = 400 │ 24 = 500 │ 32 = 2 x 400

Verify the shelves and the client's moulds

Verify that the manhole is screwed closed

Verify the belt tension and the chain spring tension (compressed to 4 3/8'')

Understand how to use the oven in a proper and secure fashion.

Understand how the digital control panel works.

Understand who to contact for service.

Customer's name (print): Signature:

Installer's name ( print): Signature:

Loading...

Loading...