PN 350-025004-09

Page | 18

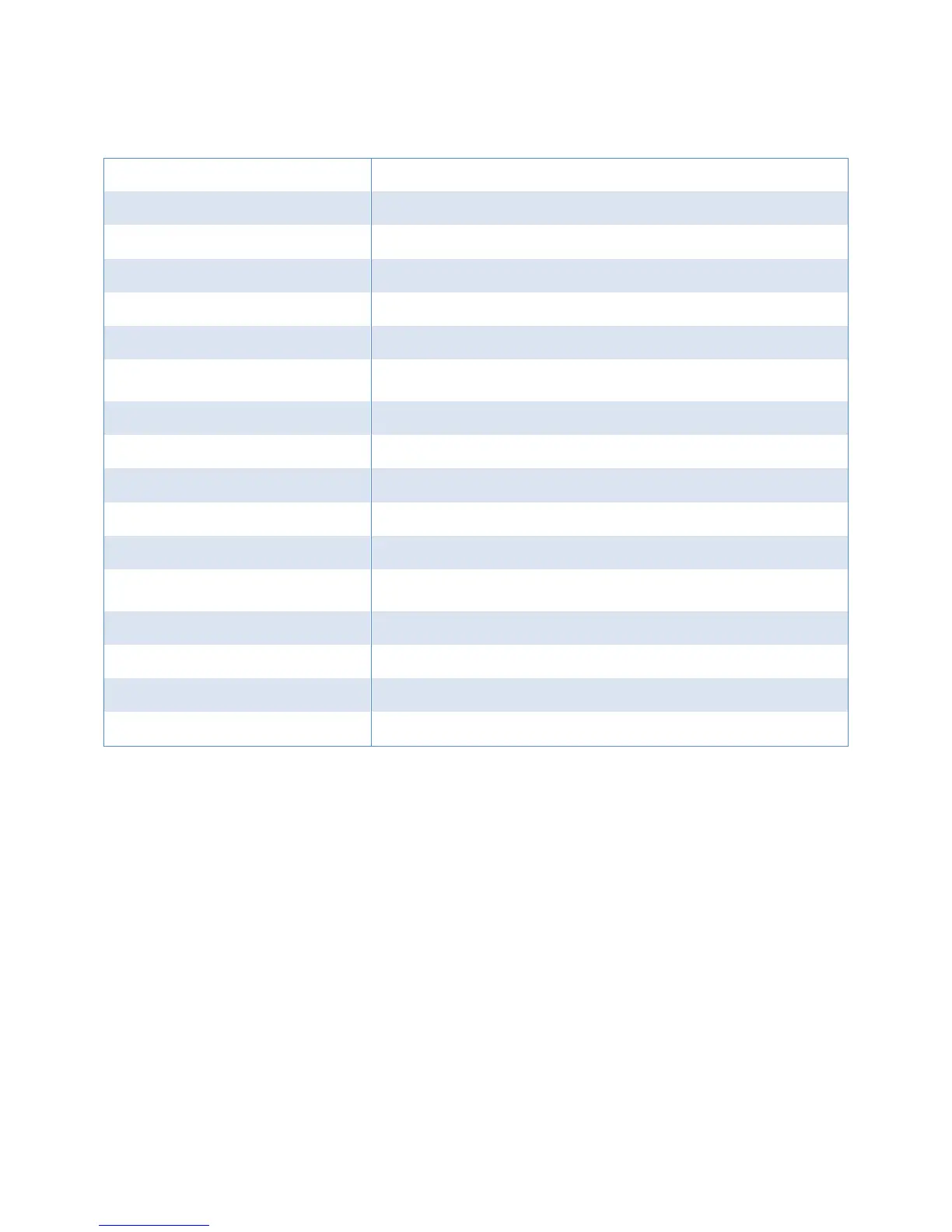

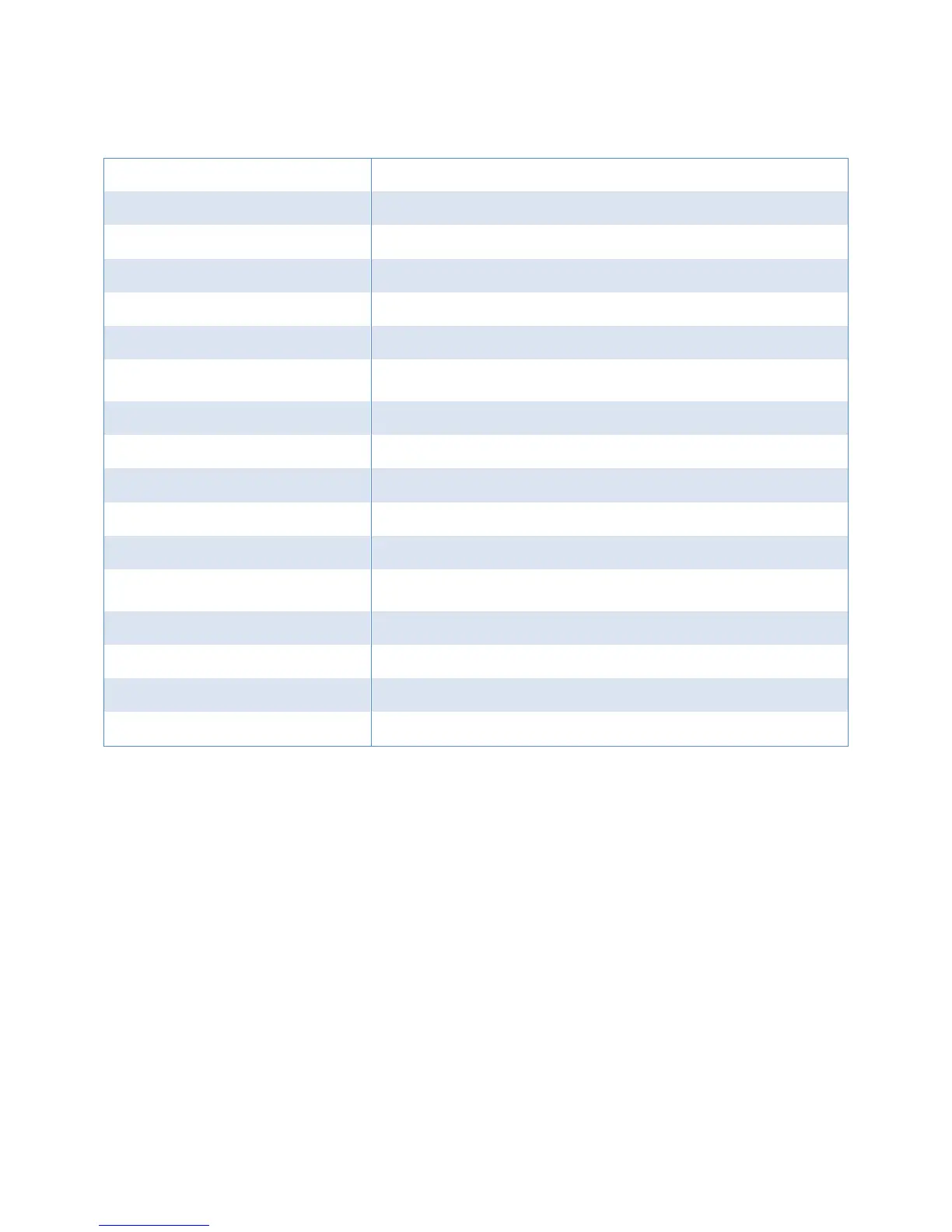

Specifications

ATR Crystal Choices Diamond/ZnSe, Ge, ZnSe, Si

Crystal Plate Mounting User changeable plates

Crystal Plate Mount Stainless steel

Angle of Incidence 45 degrees, nominal

Crystal Dimensions, Surface 1.8 mm (single reflection), 6.0 mm (multiple reflection)

Pressure Device Rotating, continuously variable pressure; click stop at maximum.

Digital Force Adapter (option)

Load cell sensor for precise and reproducible pressure control.

Attaches directly to MIRacle clamp. Digital readout.

Maximum Pressure 10,000 psi (single reflection)

Sample Access 55 mm, ATR crystal to pressure mount

Heating Options Ambient to 60 or 130 °C maximum

Accuracy +/- 0.5%

Sensor Type 3 wire Pt RTD (low drift, high stability)

Temperature Control

Digital or digital with PC control (up to 10 ramps, automated data

collection, USB interface)

Input Voltage 90-264 VAC, auto setting, external power supply

Operating Voltage 2.5 A/24 VDC/50 W

Specular Reflection Option Optional, 45 degree nominal angle of incidence

Accessory Dimensions (W x D x H) 104 x 103 x 210 mm (excludes FTIR baseplate and mount)

Effects of Temperature

The PIKE Technologies MIRacle utilizes a metallic gasket to seal the crystal to its mount. This sealing

mechanism allows some flexibility and hot samples may be placed on the crystal without damaging the

crystal or seal. However, it is recommended that the temperature difference between the sample and

the crystal be no more than 30 °C. So for a crystal at room temperature, the sample may be at a

temperature of up to 50 °C. Do not exceed sample temperature greater than 60 °C when using the

single reflection diamond MIRacle ATR crystal. Apply only room temperature samples to MIRacle

3- and 9-reflection ATR plates. Please contact PIKE Technologies if you wish to place samples of a higher

temperature on the crystal surface. Heated MIRacle plates are also available and can be heated up to

130 °C (60 °C for diamond).

Loading...

Loading...