COMPONENT LUBRICANT FREQUENCY

1. ENGINE SUM LYCOMING) MIL-L-6082 LUBRICATING

PA-28RT-201 ONLY OIL, AIRCRAFT RECIPRO-

CATING ENGINE (PISTON)

GRADE AS SPECIFIED,

SAE 50 ABOVE 60°F AIR

TEMP., SAE 40 30° TO

90°F AIR TEMP., SAE 30

0° TO 70°F AIR TEMP.,

SAE 20 BELOW 10°F AIR

TEMP. 100 HRS

2. CARTRIDGE TYPE OIL FILTERS 50 HRS

3. AIR FILTERS CLEAN AS OFTEN AS

NECESSARY, EVERYDAY

UNDER SEVERE

CONDITIONS

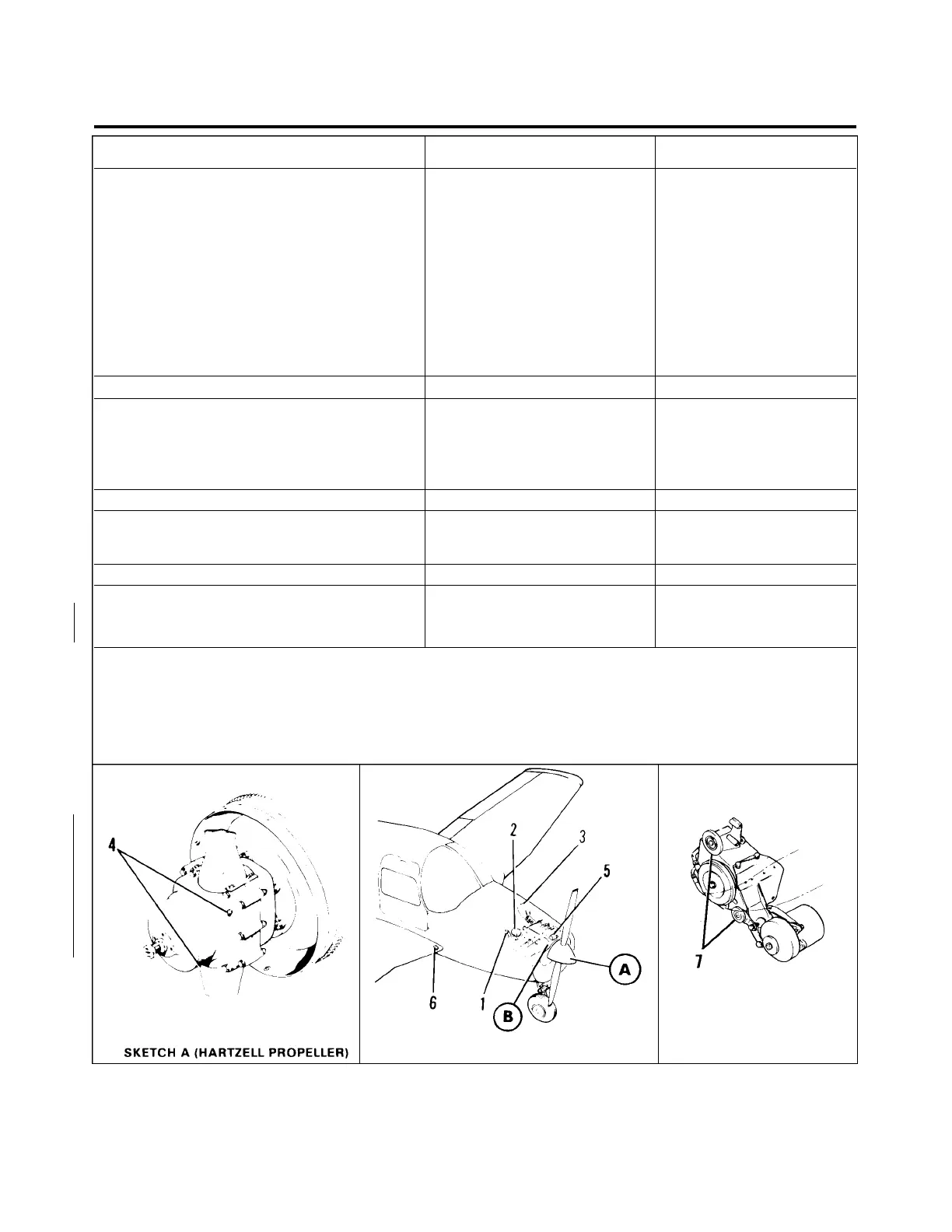

4. PROPELLER ASSEMBLY MIL-G-23827 100 HRS

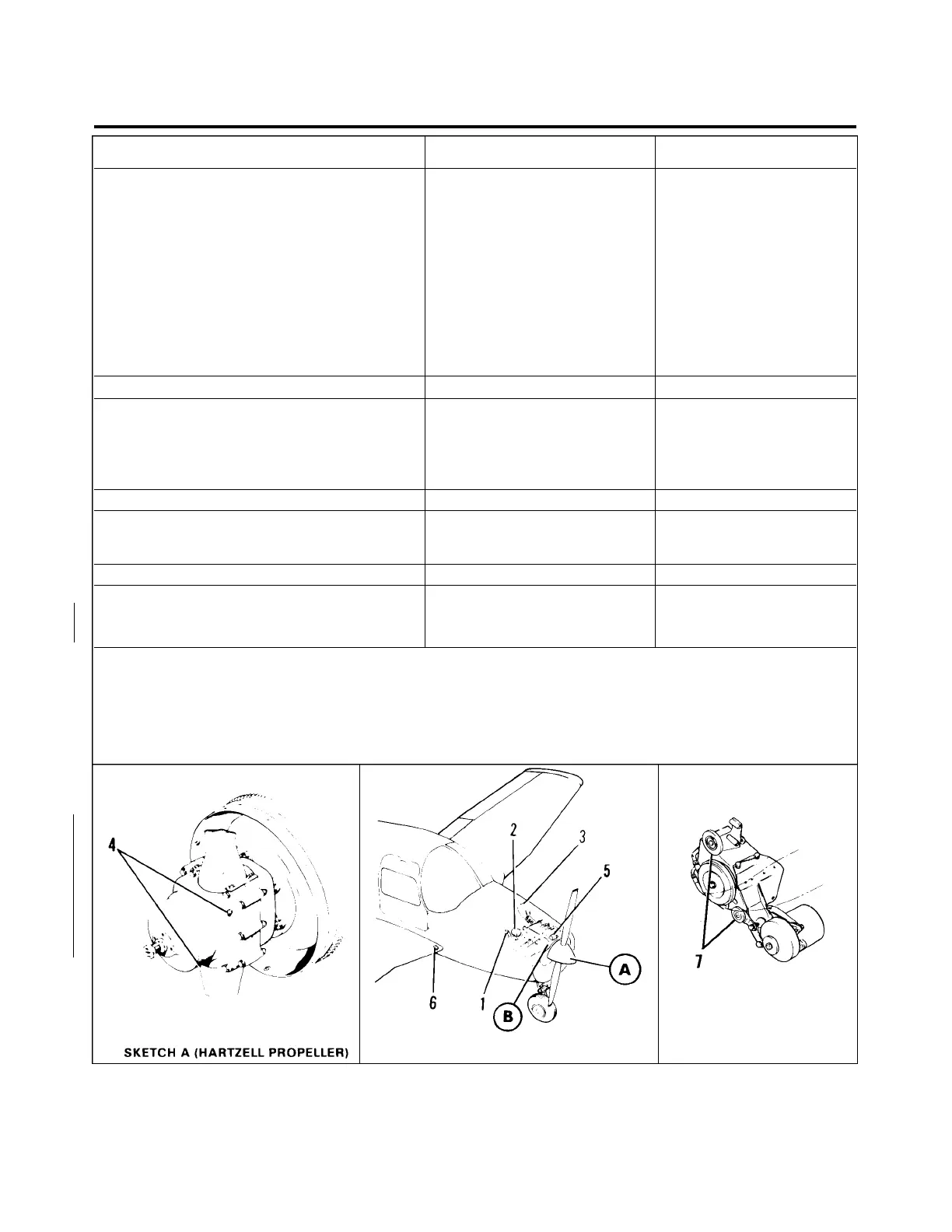

5. ENGINE CONTROL AND ENVIRONMENTAL

CONTROL PIVOT POINTS MIL-L-7870 100 HRS

6. FRESH AIR VENT SHAFTS MIL-G-7711 500 HRS

7. ALTERNATOR AND COMPRESSOR IDLER

PULLEY BEARINGS MIL-G-81322 100 HRS

SPECIAL INSTRUCTIONS

1. Air Filter - To clean filter, tap gently to remove dirt particles. Do not blow out with compressed air or use oil. Replace filter if punctured or

damaged. Air filter is located on left side of engine cowl.

2. Propeller - Remove one of the two grease fittings for each blade. Apply grease through fitting until fresh grease appears at hole of removed

fitting.

NOTE

See the latest revision of Lycoming Service Instructions No. 1014 for use of detergent oil.

Figure 12-8. Lubrication Chart (Lycoming Power Plant, Propeller and Control Pivot Points)

12-20-32

Page 12-25

Revised: February 23, 1979

1E9

PIPER AIRCRAFT

PA-28RT-201 / 201T

*MAINTENANCE MANUAL

Loading...

Loading...