Etha3 etha3

22 23

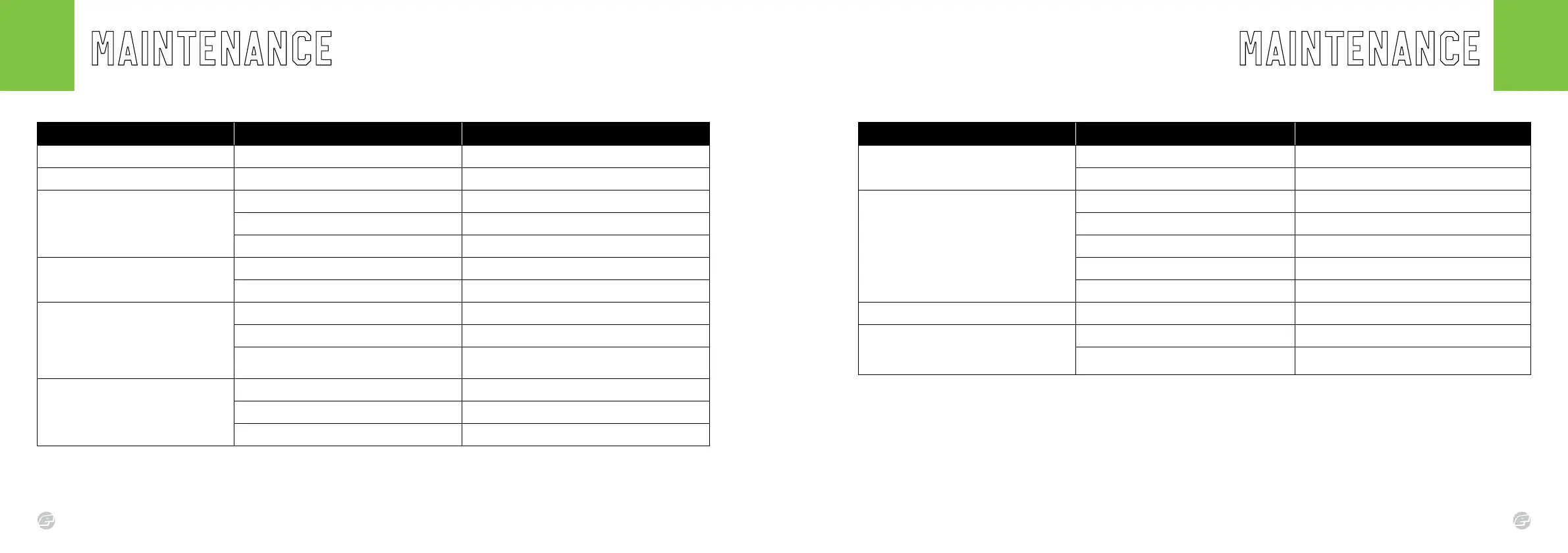

FAULT FINDING TABLES FAULT FINDING TABLES

SYMPTOM POSSIBLE CAUSE SOLUTION

Low constant velocity. The inline regulator output pressure set too low. Increase the output pressure of the inline regulator.

High velocity rst shot. The inline regulator is creeping. Strip and clean the inline regulator, replacing the regulator seal.

Velocity drop-off during rapid re.

The battery quality or charge level is low. Install a new high quality alkaline or lithium battery.

Air system regulator does not have high enough ow. Try another air system and get your current one checked out

Dirty/partially blocked inline regulator. Strip, clean, lubricate and rebuild the inline regulator.

The trigger is very ‘bouncy’.

Incorrect lter settings. Check that the DEBOUNCE settings suit your trigger set-up.

The trigger pull is too short and return strength too low. Refer to the manual’s Trigger Adjustment page to rene.

The breech sensor is not reading correctly.

The breech sensor light pipes are dirty. Keep the breech sensor light pipes clean for correct readings.

Breech sensor cover(s) are not tted correctly. Check, remove and re-t the covers correctly.

Breech sensors are damaged or bent on the PCB.

Check that the breech sensors are pointing outwards.

Make sure the sensor legs are not broken.

The breech sensor turns itself off after ring and the

display shows a breech sensor fauly.

The sensors or light pipes are dirty. Clean the breech sensors and light pipes.

The sensors are faulty. Replace the main circuit board.

The sensors are out of place. Make sure the breech sensors are pointing outwards.

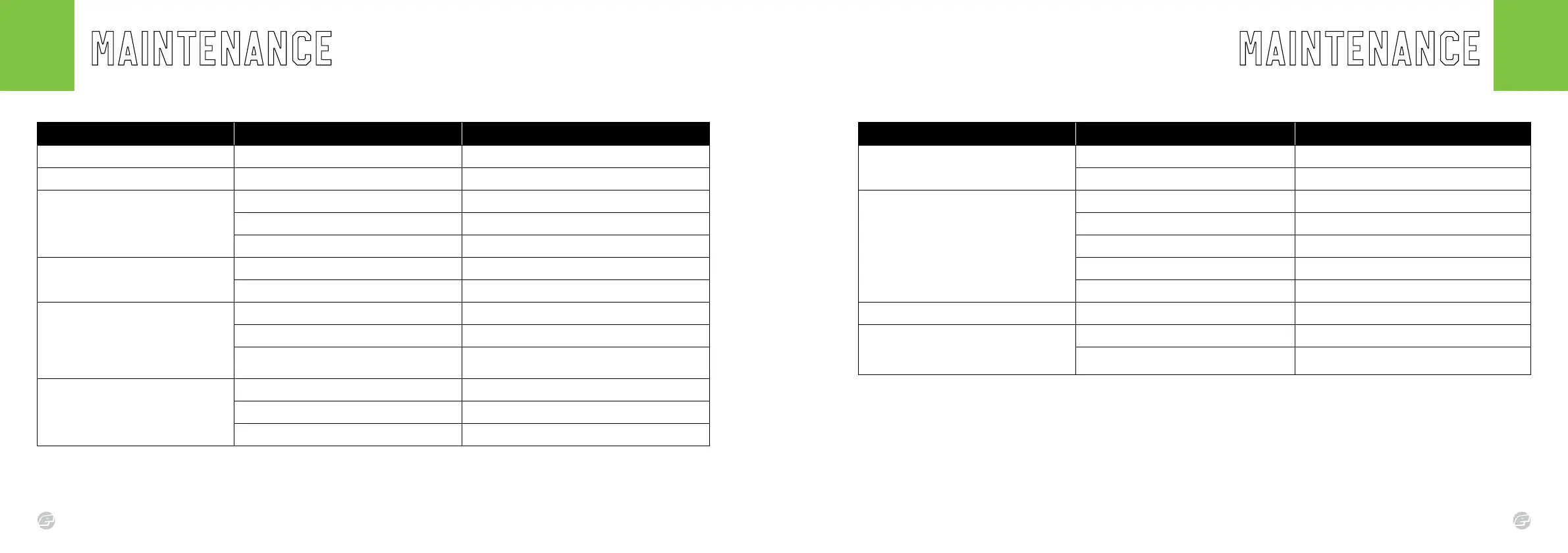

SYMPTOM POSSIBLE CAUSE SOLUTION

Two or more paintballs are being fed into the breech.

Worn, damaged or missing ball detents. Change the rubber ball detent(s).

The loader’s force setting is too high (where applicable). Reduce the loader’s force feed setting.

The marker is inconsistent.

The inline regulator is dirty. Strip and clean the inline regulator, replace seal accordingly.

The DWELL is too low. Increase the DWELL setting.

Using poor quality paintballs. Use higher grade paintballs.

Poor paintball size to barrel bore match. Find a better barrel bore size.

Inconsistent air supply from the air system. Service the air system.

The marker is inefcient. Poor paintball size to barrel bore match. Find a better barrel bore size.

Powering up, the status indicator shows WHITE or RED.

The trigger is being pulled. Release the trigger before powering up the marker.

Microswitch is permanently depressed by an incorrectly

set-up trigger.

Adjust the trigger so that it’s not being activated at rest.

Loading...

Loading...