4

SHARK 75 technical characteristics

The powerful, compact SHARK 75 model is a plasma unit that

satisfies the needs of medium / light metalwork most fully.

The cuts are always precise and ensure high cutting stand-

ards in any situation.

High quality and cutting speed thanks to the SK 75 torch, with

(HPC) High Performance Cutting technology, which ensures a

concentrated, powerful plasma beam.

Further particular features of this machine include:

•

SK 75 torch with (HPC) High Performance Cutting technol-

ogy and coaxial cable.

• Powerful, compact and light-weight, only 22,8 kg.

• High productivity thanks to high cutting quality and speed.

•

Lower operating costs due to the long lifespan of consum-

ables.

• “Energy Saving” function that starts ventilation of the gener-

ator only when necessary.

•

Electrical protective device on the torch to guarantee the op-

erator’s safety.

•

The possibility of automated CNC cutting, using the SHARK

75-M version, fitted with a straight SKM 75 torch.

The technical data for this equipment is summarized in the ta-

ble 1.

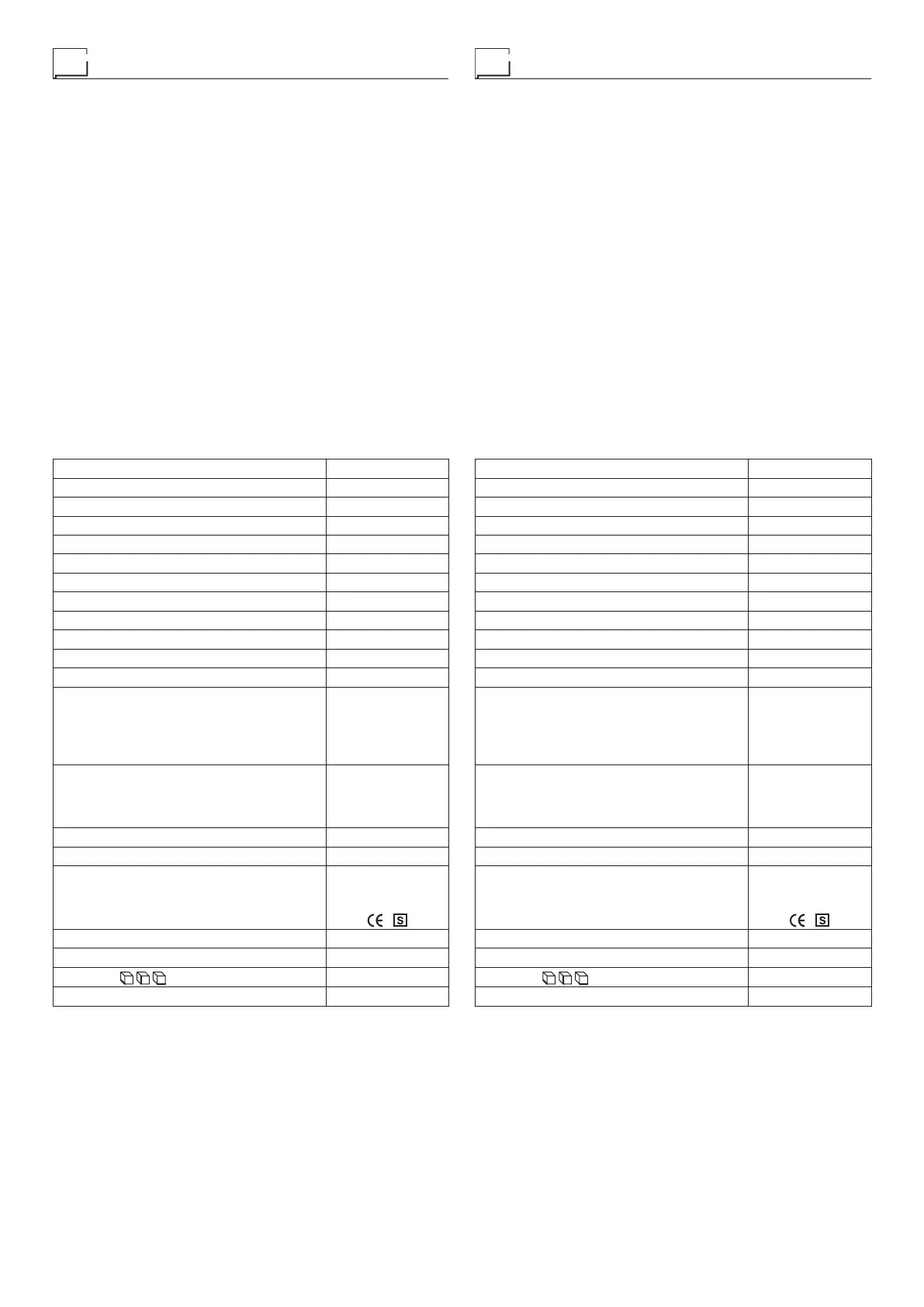

Table 1

Model SHARK 75

Three-phase power supply 50/60 Hz V 400

Mains supply: Z

max

Ω 0,107

Power input @ I

2

Max kVA 11

Delayed fuse (I

2

@ 100%) A 16

Power factor / cosφ 0,87 / 0,99

Efficiency degree η 0,85

Open circuit voltage (peak) V 300

Current range A 20 ÷ 70

Duty cycle @ 100% (40°C) A 55

Duty cycle @ 60% (40°C) A 65

Duty cycle @ 40% (40°C) A 70

Cutting capacity

recommended

maximum

severance

piercing

mm

mm

mm

mm

20

25

30

15

Type of machine intake air/gas

AIR - Clean, dry,

oil-free for ISO 8573-1

Class 1.2.2

N2 - 99.95%

Air pressure 5,0 ÷ 5,5

Air flow 180 ÷ 210

Standards

IEC 60974-1

IEC 60974-7

IEC 60974-10

Protection class IP 23 S

Insulation class F

Dimensions

mm 595-390-185

Weight kg 22,8

WARNING: This equipment complies with EN/IEC 61000-3-12 pro-

vided that the maximum permissible system impedance Z

max

is less

than or equal to 0,107 at the interface point between the user’s sup-

ply and the public system. It is the responsibility of the installer or user

of the equipment to ensure, by consultation with the distribution net-

work operator if necessary, that the equipment is connected only to a

supply with maximum permissible system impedance Z

max

less than

or equal to 0,107.

This system, tested according to EN/IEC 61000-3-3, meets the re-

quirements of EN/IEC 61000-3-11.

SHARK 105 technical characteristics

The powerful, compact SHARK 105 model is a plasma unit

that satisfies the needs of medium / light metalwork most fully.

The cuts are always precise and ensure high cutting stand-

ards in any situation.

High quality and cutting speed thanks to the SK 125 torch, with

(HPC) High Performance Cutting technology, which ensures a

concentrated, powerful plasma beam.

Further particular features of this machine include:

•

SK 125 torch with (HPC) High Performance Cutting technol-

ogy and coaxial cable.

• Powerful, compact and light-weight, only 23,9 kg.

• High productivity thanks to high cutting quality and speed.

•

Lower operating costs due to the long lifespan of consum-

ables.

• “Energy Saving” function that starts ventilation of the gener-

ator only when necessary.

•

Electrical protective device on the torch to guarantee the op-

erator’s safety.

•

The possibility of automated CNC cutting, using the SHARK

105-M version, fitted with a straight SKM 125 torch.

The technical data for this equipment is summarized in the ta-

ble 2.

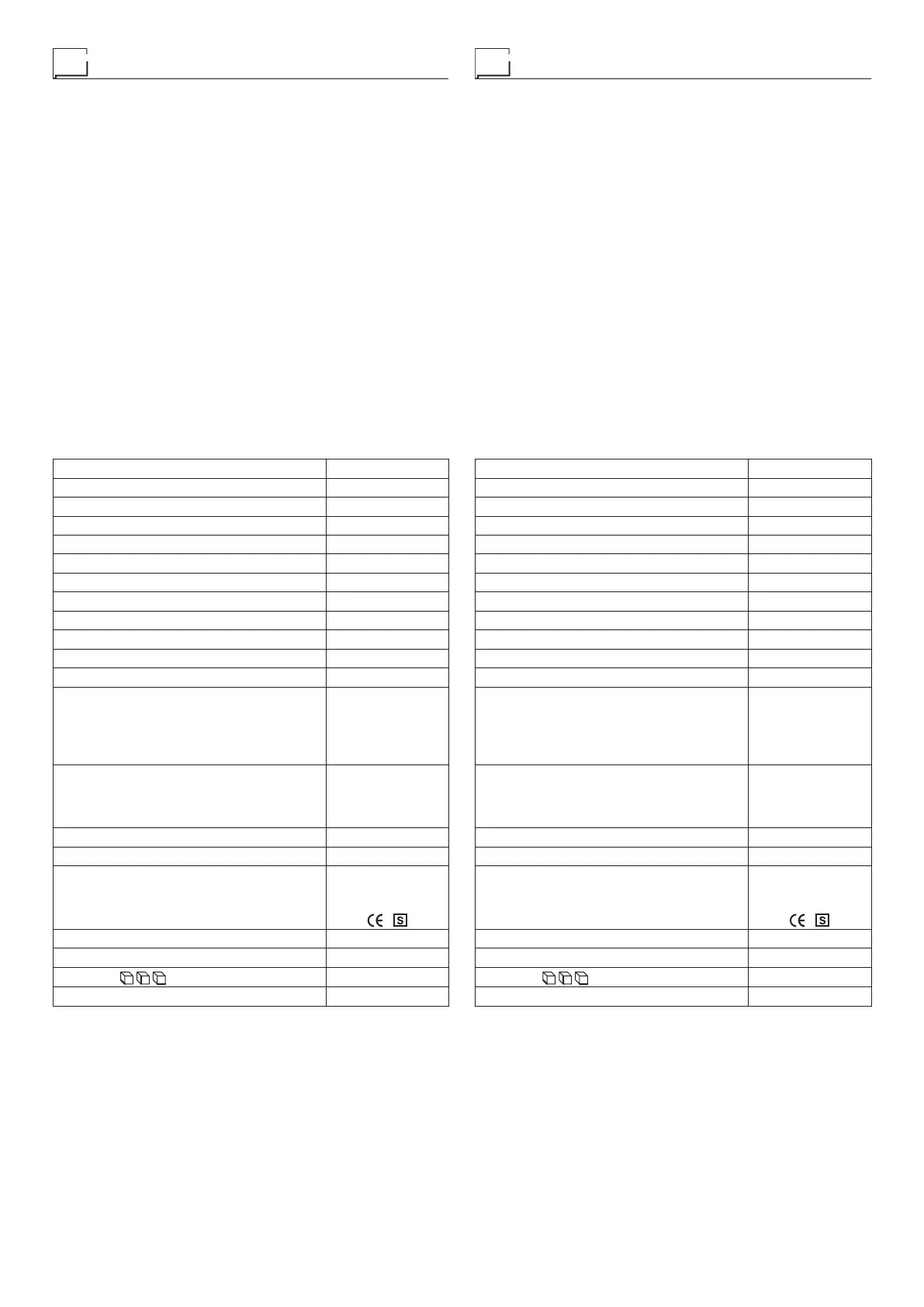

Table 2

Model SHARK 105

Three-phase power supply 50/60 Hz V 400

Mains supply: Z

max

Ω 0,109

Power input @ I

2

Max kVA 15

Delayed fuse (I

2

@ 100%) A 16

Power factor / cosφ 0,90 / 0,99

Efficiency degree η 0,85

Open circuit voltage (peak) V 300

Current range A 20 ÷ 100

Duty cycle @ 100% (40°C) A 70

Duty cycle @ 60% (40°C) A 90

Duty cycle @ 40% (40°C) A 100

Cutting capacity

recommended

maximum

severance

piercing

mm

mm

mm

mm

30

35

40

20

Type of machine intake air/gas

AIR - Clean, dry,

oil-free for ISO 8573-1

Class 1.2.2

N2 - 99.95%

Air pressure 5,0 ÷ 6,0

Air flow 280 ÷ 330

Standards

IEC 60974-1

IEC 60974-7

IEC 60974-10

Protection class IP 23 S

Insulation class F

Dimensions

mm 595-390-185

Weight kg 23,9

WARNING: This equipment complies with EN/IEC 61000-3-12 pro-

vided that the maximum permissible system impedance Z

max

is less

than or equal to 0,107 at the interface point between the user’s sup-

ply and the public system. It is the responsibility of the installer or user

of the equipment to ensure, by consultation with the distribution net-

work operator if necessary, that the equipment is connected only to a

supply with maximum permissible system impedance Z

max

less than

or equal to 0,107.

This system, tested according to EN/IEC 61000-3-3, meets the re-

quirements of EN/IEC 61000-3-11.

Loading...

Loading...