43

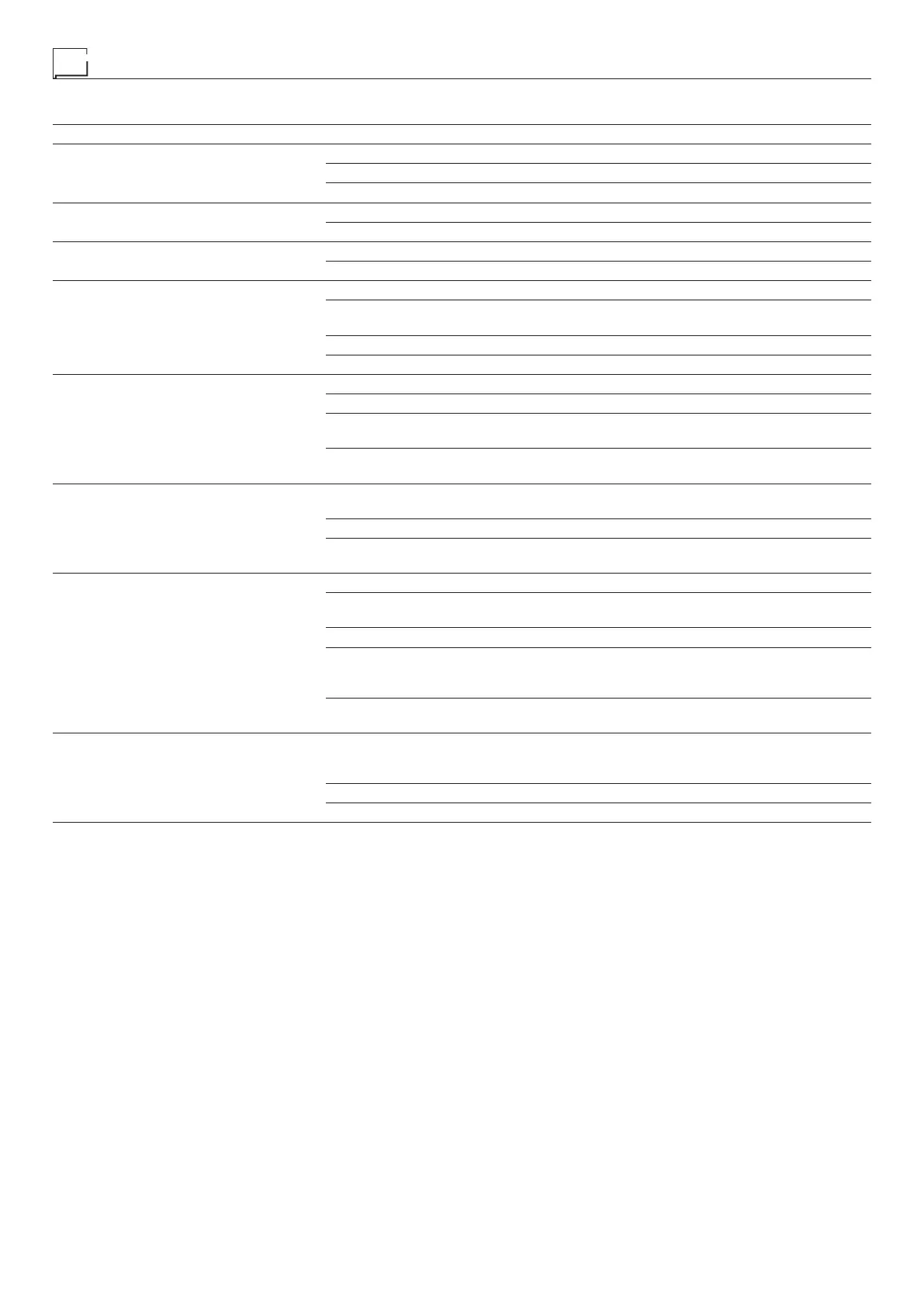

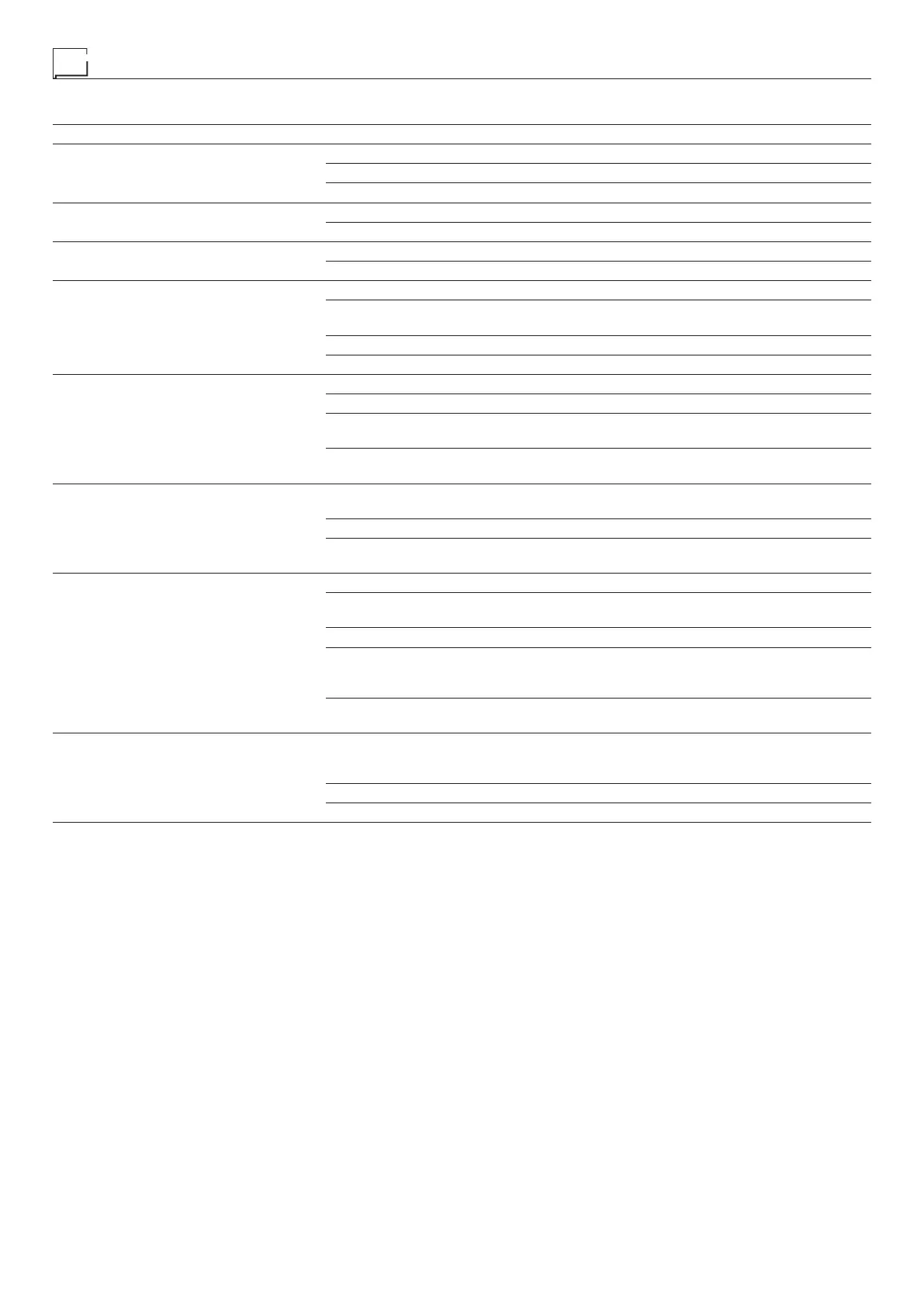

Common cutting defects

The table below provides an overview of common cut defects that can arise when using the machine, and explains how to re-

solve them.

Defect Cause Remedy

Insufficient penetration • Cutting speed too high • Reduce speed

• Current too low • Increase current

• Ground wire connected wrong • Check ground wire connection

Main arc goes out • Cutting speed too slow • Increase speed

• Excessive erosion of electrode • Replace electrode

Excessive residues • Cutting speed too slow • Increase speed

• Electrode hole eroded • Replace electrode

Nozzle overheated or black • Current too high • Reduce current

• Gap between the nozzle and

workpiece too small.

• Increase space

• Air dirty • Clean air filter

• Excessive erosion of electrode • Replace electrode

Pilot arc intermittent or sparking • Air dirty, greasy, wet • Clean air filter

• Pilot arc current too low • Check the equipment pilot arc circuit

• The air filter element is polluted,

replace the element.

• Replace the element.

• Check that there is no

moisture in the air circuit.

• Install or repair the generator's

air filter system.

The arc goes out but ignites again

when the torch button is pushed again

• Consumables worn or damaged • Inspect consumable components

and replace them

• Air dirty and polluted • Replace the air filter element

• Air pressure incorrect • Make sure the air pressure

is at the correct level

The quality of the cut is poor • Torch not used correctly • Check that the torch is used correctly

• Consumables worn or damaged • Check that the consumables are

not worn, and replace if necessary

• Incorrect pressure or poor quality air • Check the air pressure and quality

• Cutting mode selector in

incorrect position

• Check that the cutting mode

selector is in the correct position

for the cutting operations.

• Consumables not correct

or fitted incorrectly

• Check that the correct

consumables are fitted

The arc is not transferred to the plate • Ground wire connected wrong • Clean the contact area between

the earth clamp and the plate,

to ensure a good connection

• Earth clamp damaged • Repair or replace the earth clamp

• Piercing distance too great • Reduce the distance

Loading...

Loading...