13

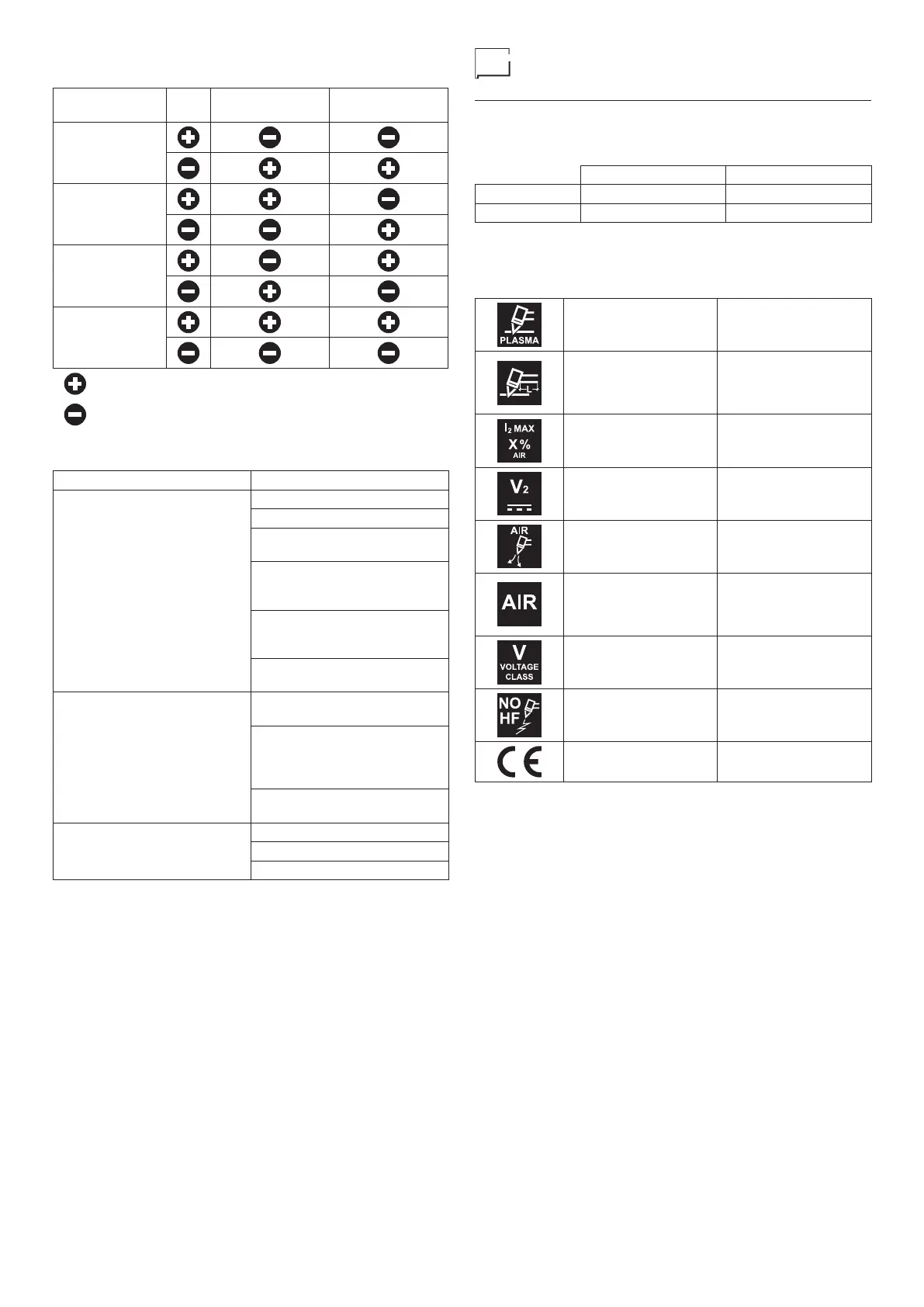

The following actions have the relevant effect on the gouge

profile:

Gouge profile

width

Gouge profile

depth

Torch speed

Distance

between torch

and plate

Torch angle

Generator

current

= increase (or more vertical angle)

= decrease (or less vertical angle)

COMMON ERRORS FOR MANUAL CUTTING

Problem Cause

The torch does not cut the

plate completely.

The cutting speed is too high.

The consumables are worn.

The metal to be cut is too thick

for the voltage selected.

Gouging consumables are

fitted, instead of cutting

consumables.

The earth clamp is not

connected to the plate

correctly.

The gas pressure or flow rate

is too low.

The quality of the cut is poor. The metal to be cut is too thick

for the voltage.

The wrong consumables are

being used (e.g. gouging

consumables are used instead

of cutting consumables).

The torch is being moved too

fast or too slow.

The arc splutters and the

lifespan of consumables is

shorter than envisaged.

Moisture in the gas supply.

Incorrect gas pressure.

Consumables fitted incorrectly.

Configuring the torch for

automatic cutting

INTRODUCTION

These machines are supplied with the following standard torch-

es for automatic cutting:

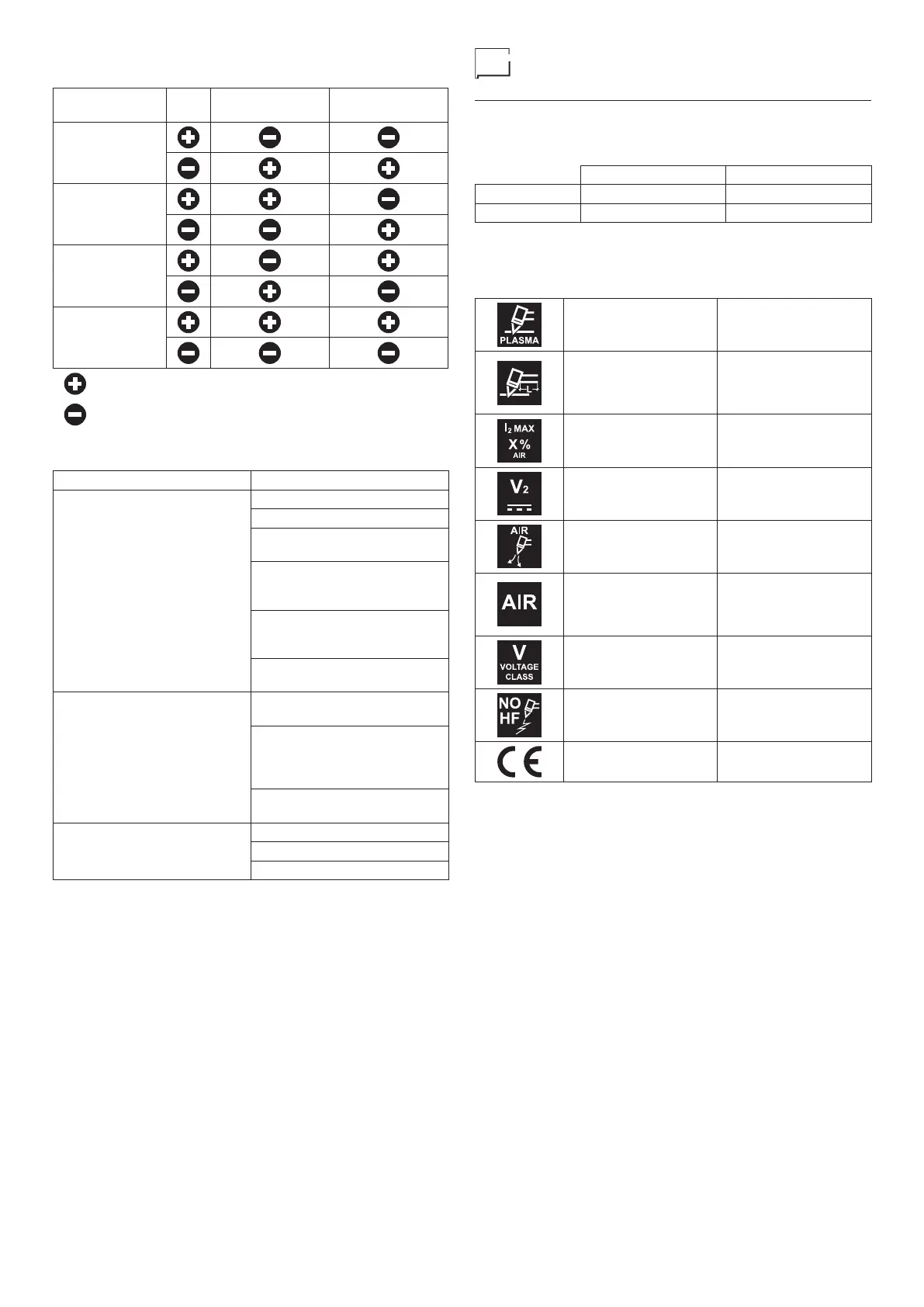

Torch Length

SHARK 75/M SKM 75 6-12 m

SHARK 105/M SKM 125 6-12 m

Other lengths are available by request.

The torches are air cooled, and do not require special cooling.

The main nominal characteristics of the torches supplied, are

as follows:

SKM 75 SKM 125

SKM 75 = 6/12 m

(standard)

(other lengths by

request)

SKM 125 = 6/12 m

(standard)

(other lengths by

request)

70 A @ 50%

(10 min. 40°C)

125 A @ 60%

(10 min. 40°C)

DC DC

5,0-5,5 bar - 72-80 psi

185 l/min - 390 cfh

5,0-6,0 bar - 72-87 psi

295 l/min - 630 cfh

AIR - Clean, dry, oil-

free for ISO 8573-1

Class 1.2.2

N

2

- 99.95%

AIR - Clean, dry, oil-

free for ISO 8573-1

Class 1.2.2

N

2

- 99.95%

M M

Without HF Without HF

IEC 60974-7 IEC 60974-7

WORKING LIFESPAN OF CONSUMABLES

The following factors affect the frequency with which consum-

ables need to be replaced:

• Thickness of the metal cut.

• Average cut length.

• Air quality (presence of oil, moisture, or other pollutants).

• Execution of piercing of the metal or cutting from the edge.

• Correct piercing depth.

•

Cutting done using mesh or solid material cutting mode. Cut-

ting done in mesh mode give rise to more wear of consum-

ables.

Under normal conditions, the nozzle wears out before the oth-

er consumables during cutting operations.

Loading...

Loading...