14

100A

125A

100-125A

45A

85A

45A

85A

45-85A

100A

125A

100-125A

105A

105 A CONTACT CUT

SKM 125

SKM 75

486029

486026

487636 408612 425023 482136

486049

486027

487629

408610 (70 A)

408609 (50 A) 482134 425022

45-85A

45-85A

45A

45A

45A65A85A

45A

85A

45 A max CLEAN-CUT

486028482030 408613 425023 482135

408614 (45 A)

408615 (65 A)

408616 (85 A)

425023 482135

45-85 A CONTACT CUT

45A

85A

486028

486025

486025

487635

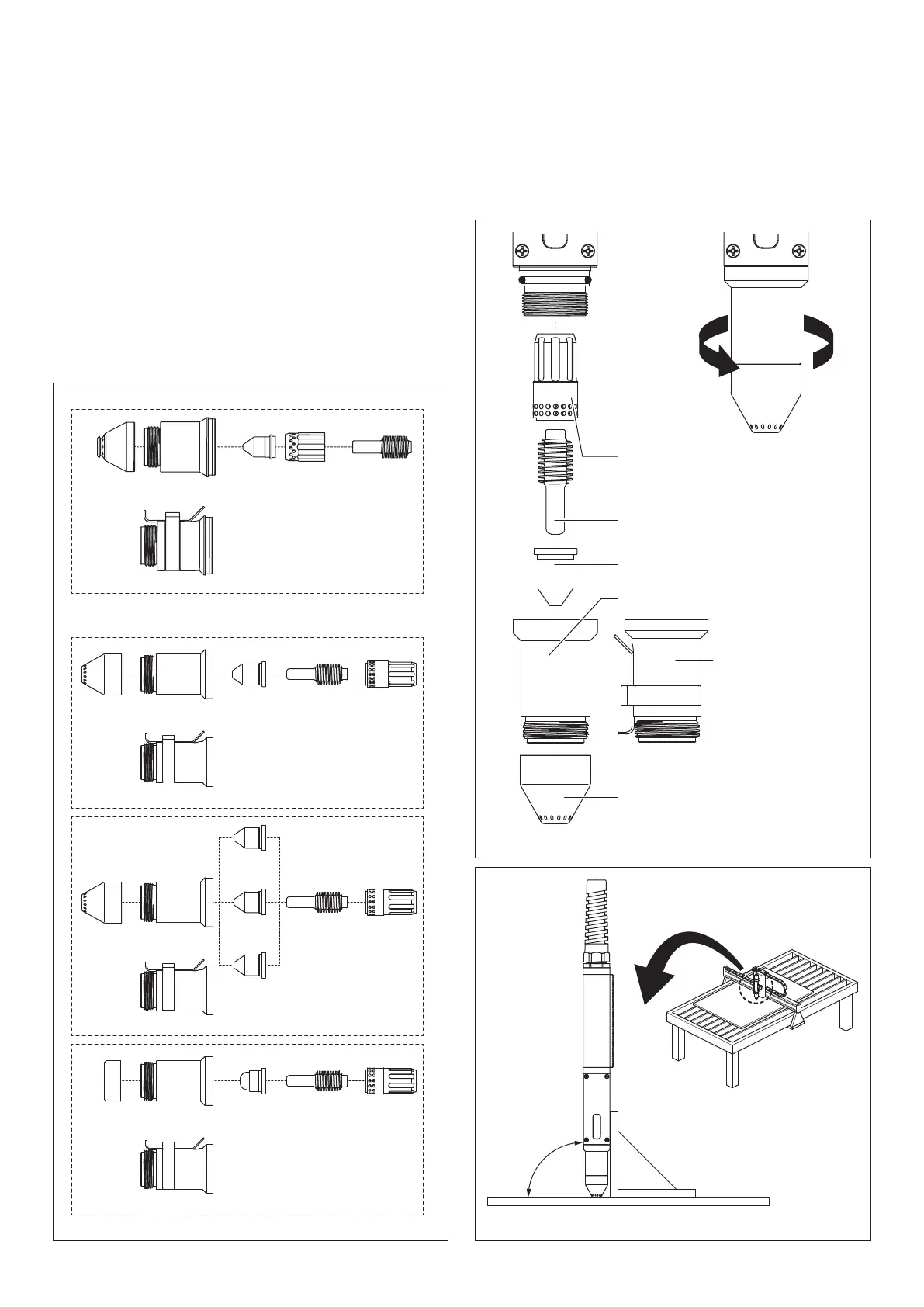

90°

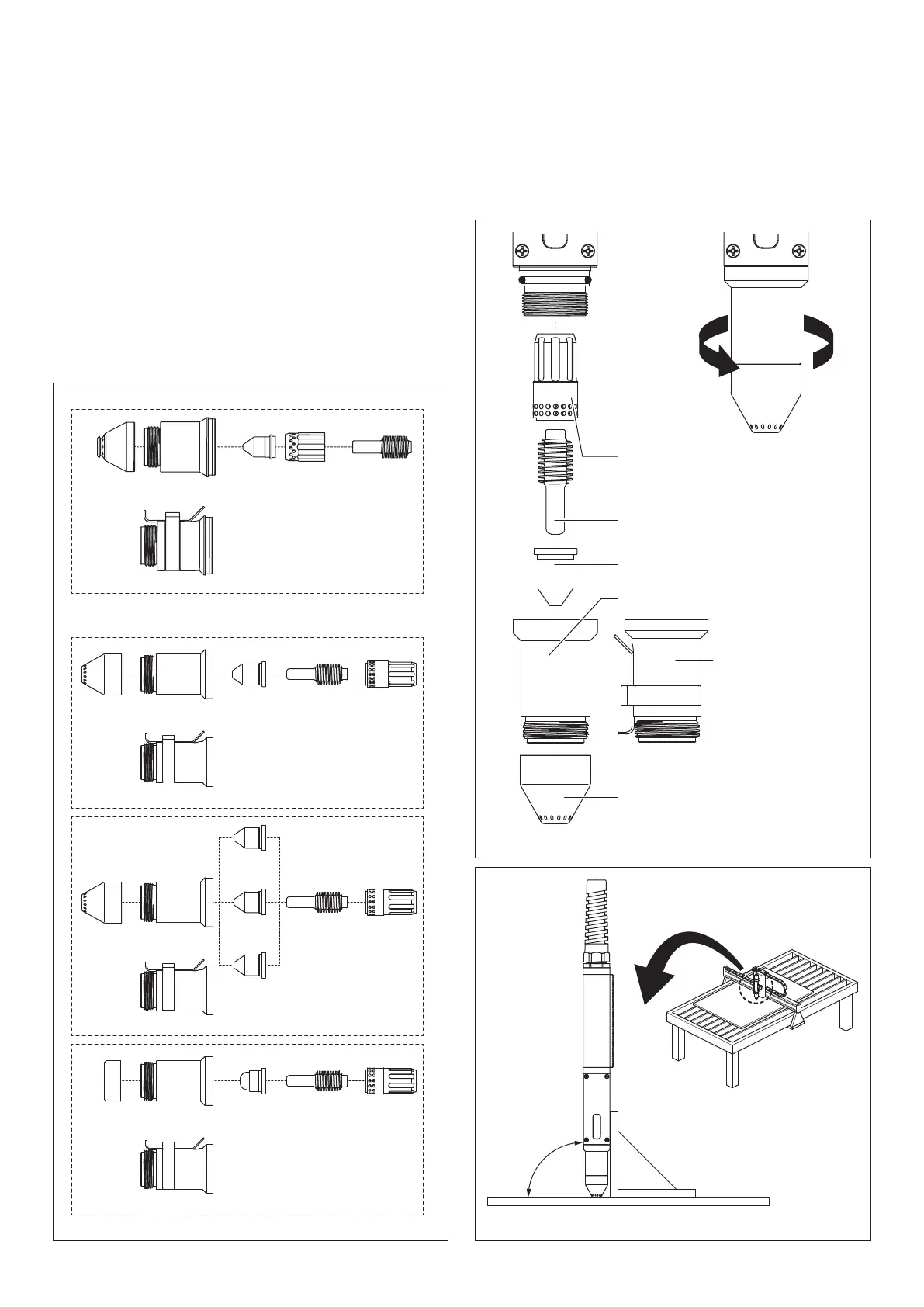

FIG. I FIG. M

FIG. L

Air diffuser

Electrode

Nozzle

Outer nozzle holder

Outer nozzle holder

with Ohmic sensor

Shield

CONSUMABLES FOR AUTOMATIC CUTTING

Figure I shows the consumables used for the plasma torches

supplied, complete with the CEA order codes.

To improve the quality of cuts for thin metals (about 2 mm or

less) CLEAN-CUT consumables should preferably be used,

with maximum cutting currents of 45 A (only for SKM 125 torch).

FITTING CONSUMABLES ON THE TORCH FOR

AUTOMATIC CUTTING

WARNING: Before changing consumables, check that the ma-

chine’s main switch is in the O position.

To use the torch for automatic cutting, a complete set of con-

sumables must be fitted, as shown in figure L. An outside noz-

zle holder is available with an Ohmic sensor, which is to be

used with shielded consumables.

EQUIPPING THE TORCH FOR AUTOMATIC CUTTING

The SKM series of torches for automatic cutting can be fitted on

a wide range of X-Y-Z benches, motorised equipments, bevel-

lers for tubes, and other equipment. Install the torch according

to the manufacturer’s instructions.

Fit the SKM torch perpendicular to the plate, to achieve a verti-

cal cut. Use a square to align the torch at 90° (Fig. M).

Loading...

Loading...