5

Opening the packaging

The standard composition of this plasma cutting system is

made up of:

• Plasma cutting units.

•

Plasma torch with centralised connection and initial supply

spare parts kit.

• Ground cable.

• Trolley for transportation (optional).

On receipt of the unit, perform the following operations:

• Remove the plasma cutting unit and all relative accessories

and components from the packaging.

•

Check that the plasma cutting unit is in good condition. If it is

not, inform your dealer immediately.

•

Make sure that all the ventilation louvers are open and that

the airflow is not obstructed.

Plasma cutting

The cutting system used by this equipment is a low current sys-

tem that uses compressed air as its plasma equipment as well

as for cooling. The air normally used is a mixture of 79% nitro-

gen and 21% oxygen. These two biatomic gasses have almost

identical enthalpy and form a highly energetic blend. The low

current also makes it possible to use torches with a low air ca-

pacity and moderate cutting speed, that are more suitable for

manual procedures.

CUTTING PARAMETERS

In analyzing the parameters that characterize manual plasma

cutting it is necessary to note that they depend on the material

to be cut, its thickness and the skill of the operator in following

the cutting line. Optimum speed depends largely on the skill of

the operator and amount of material to be cut and is achieved

when the fused material flows through the groove and is not

projected in the direction of the torch. If the latter occurs, cut-

ting speed has to be reduced.

The parameters that affect cutting are:

•

Electric power. Any increase in electric power will permit

higher cutting speed and greater thickness of the material

to be cut

• Compressed air capacity. Increasing the air capacity ena-

bles cutting thicker material and ensures better quality at

any thickness

•

Distance between the nozzle and workpiece. The appear-

ance of the cut and wear of the torch’s working parts, de-

pend on the correct distance between the nozzle and the

workpiece.

NOTE: The width of the cut path is equal to about twice the di-

ameter of the hole in the nozzle.

Respect of the above recommendations ensures greatly redu-

ced thermal alterations of the material due to cutting, that are in

any case always fewer than those caused by oxygen tor ches.

The thermally altered zone is in any case smaller than the zone

on which the weld is effective, so that in welding pieces that

have been cut by plasma it is not necessary to perform any

cleaning or grinding operations.

Installation

The place where the equipment is installed should be selected

with care so as to ensure satisfactory, safe use.

The user is responsible for installation and use of the equip-

ment according to the instructions provided by the manufactu-

rer in this manual.

Temperatures must be between -25 °C e +55 °C. during tran-

sportation and/or storage in stores.

Before installing the equipment the user should take into con-

sideration any possible electromagnetic problems in the work

area.

In particular, we recommend that the equipment not be instal-

led in the vicinity of:

• Signalling, control and telephone cables.

• Radiotelevision transmitters and receivers.

• Computers or controlling and measuring instrument.

• Safety and protection devices.

If the operator wears a pacemaker, hearing aid or other sim-

ilar device, he should consult his doctor before approaching

the equipment while it is running. The environment where the

equi pment is installed must conform with the degree of protec-

tion of the chassis that is IP 23 S (IEC publication 60529). The

system is capable of working in environments where working

condi tions are particularly hard.

This equipment cools water by forced circulation of air and must

therefore be positioned in such a way that the air can easily

be drawn in and expelled through the openings in the chassis.

Connection to the electrical supply

Connection of the machine to the user line (electrical cur-

rent) must be performed by qualified personnel.

Before connecting the cutting equipment to the mains sup-

ply, check that the data on the machine plate corre spond

to the supply voltage and frequency and its main switch

is on the “0” position.

This system has been designed for nominal voltage 400 V -

50/60 Hz.

The connection to the supply, should be made with four core

cable which is supplied with the machine, connecting:

• Three wires the supply.

• The fourth one, YELLOW-GREEN, to ground.

Connect a suitable plug (3p+e) of proper capacity to the

mains cable and fix to a socket fitted with fuses or auto-

matic switch: the proper ground terminal must be con-

nected to the ground connector (yellow-green) of the main

supply.

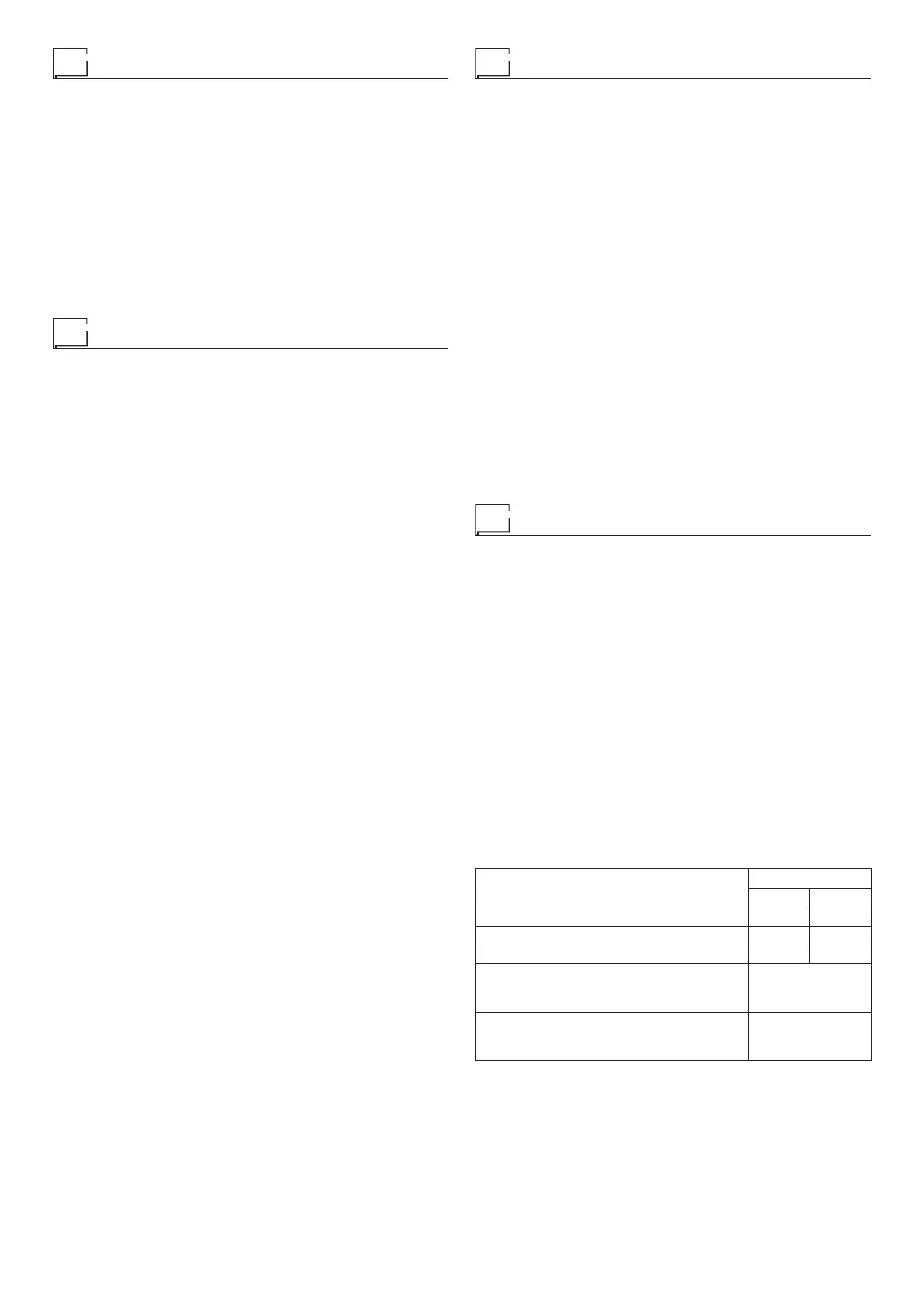

Table 3 shows the capacity values that are recommended for

fuses in the line with delays.

Table 3

Model

SHARK

75 105

Power input @ I

2

Max kVA 11 15

Delayed fuse (I

2

@ 100%) A 16 16

Duty cycle @ 40% (40°C) A 70 100

Mains supply connection cable

Length

Section

m

mm

2

4

2,5

Ground cable

Length

Section

m

mm

2

4

10

NOTE: If extensions of the power supply cable are used, they

must be of adequate cross section and never inferior to that of

the cable supplied.

Loading...

Loading...