6

Usage norms

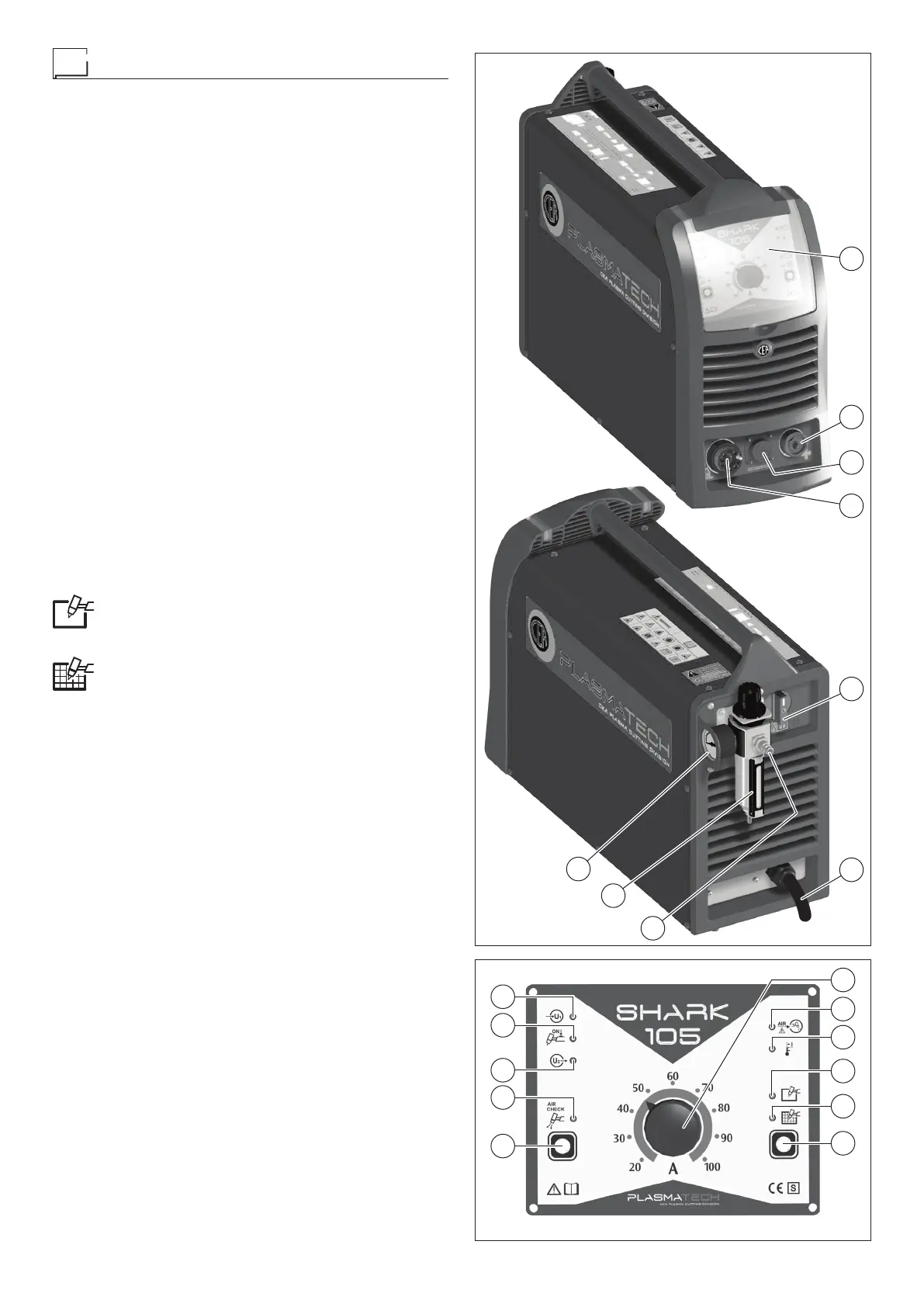

COMMAND AND CONTROL DEVICES (Fig. A)

Pos. 1 Control panel (Fig. B).

Pos. 2 Snap-in connector for ground line.

Pos. 3 Connector, 14 pole, for CNC control interface (option-

al extra).

Pos. 4 Centralised torch attachment.

Pos. 5 Power supply switch.

Pos. 6 Cutting machine power supply cable.

Pos. 7 Fast coupling to connect compressed air tube.

Pos. 8 Filter and cutting air pressure regulator. The air filter

automatically expels impurities.

Pos. 9 Pressure gauge for reading cutting air pressure.

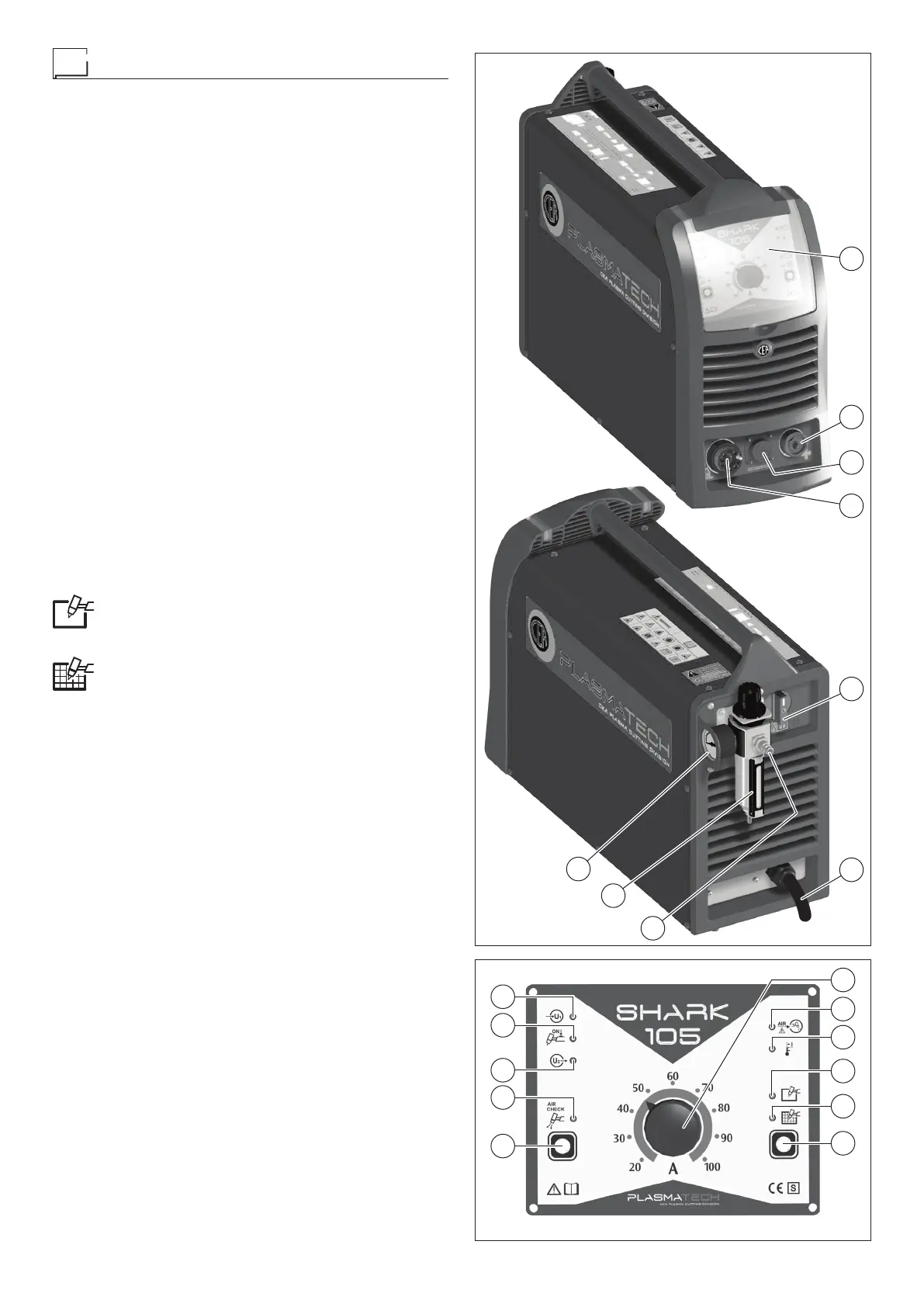

CONTROL PANEL (Fig. B)

Pos. 1 Cutting current adjustment knob.

Pos. 2 Yellow LED: signals lack of compressed air. It lights

up when air pressure is below the set value.

Pos. 3 Yellow LED: signals intervention of overheat cutoff.

This LED shines to indi cate that the overheating pro-

tection has cut in because the work cycle is not being

followed. After several minutes the overheat cut-off

rearms automatically (and the yellow LED turns itself

off) and the welder is ready for use again.

Pos. 4 Green selection LED for full cut mode. When this LED

is switched on, it means that the operator has set the

cutting mode for solid material.

Pos. 5 Green selection LED for mesh cutting mode. When

this LED is switched on, it means that the operator

has set the cutting mode for mesh material.

Pos. 6 Cutting mode selection button.

This can be used to select one of the 2 cutting modes,

as indicated by the corresponding LED that switches

on:

•

Solid material mode (when the torch button is

pushed, when the operator goes out of the work-

piece during cutting, the arc switches off automati-

cally).

•

Mesh material mode (when the torch button is

pushed, when the operator goes out of the work-

piece during cutting, the pilot arc ignites again au-

tomatically, to allow cutting to continue).

Pos. 7 Compressed air button.

When this button is pushed and released, the cutting

air valve opens, allowing the operator to regulate the

compressed air pressure, using the filter / regulator

knob (Pos. 8, Fig. A) located on the back panel.

The pressure gauge (Pos. 9, Fig. A) provides a read-

ing for the cutting air pressure.

The operation is terminated manually by pushing the

cutting torch button, or automatically after a time of

about one minute.

Pos. 8 Green compressed air button LED

When this LED is switched on, this means the oper-

ator is doing the compressed air test.

Pos. 9 Red inverter switch on indication LED. The machine

is “on” and ready for the cutting operation.

Pos. 10 Red LED: signals activation of torch button. When

the torch button is pushed, the LED switches on and

the machine checks correct functioning of the plas-

ma torch connection.

Pos. 11 Green LED - power supply on. When on the system

is powered and ready for use.

1

2

5

6

8

9

3

4

FIG. A

6

5

4

3

2

1

10

9

8

7

11

FIG. B

Loading...

Loading...