15

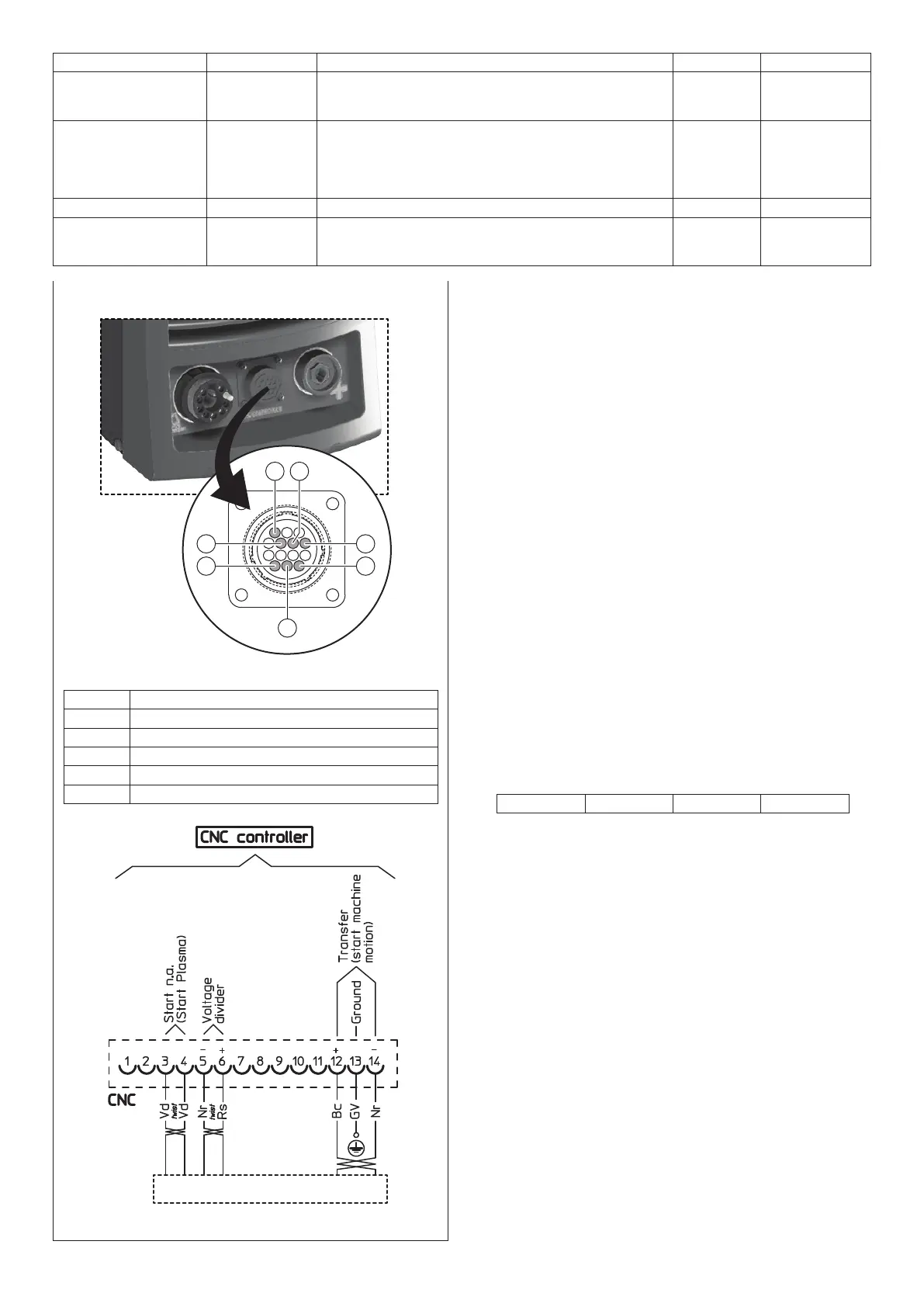

FIG. N

13

12

4

14

6

3 5

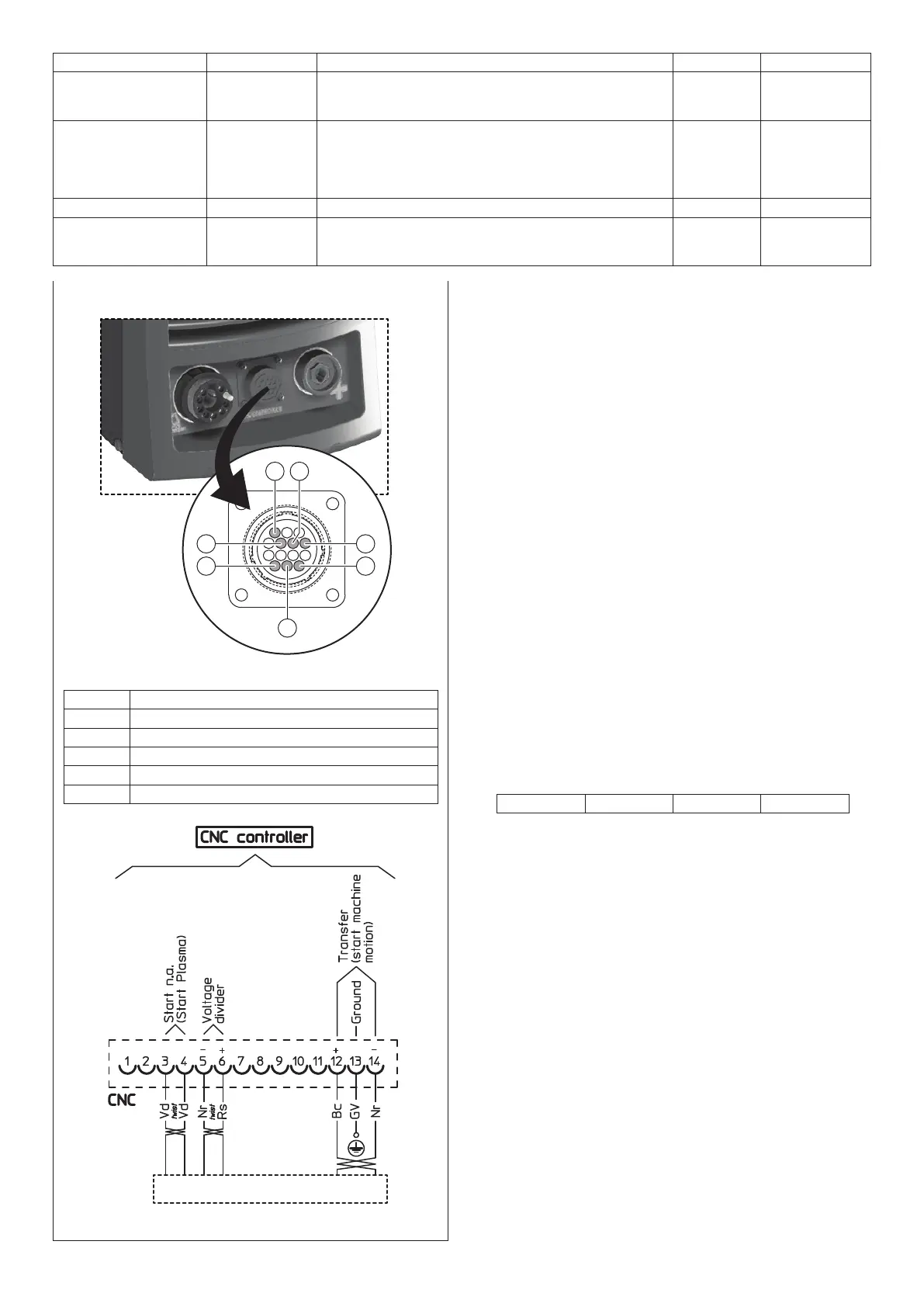

Signal Type Notes Pole n° Wire colour

Start cut Input An isolated contact has to be closed for activation to

occur. The characteristics of this contact are: voltage >

20 Vdc; current > 10 mA.

3

4

Green

Green

Arc transferred

Start machine

movement

Output Closure of isolated photo relay contact. This contact’s

characteristics are as follows:

• Max voltage 60 Vdc

• Max current 400 mAdc

Alternating current (AC) is not allowed.

12 (+)

14 (-)

White (+)

Black (-)

Earth protection (PE) Earth 13 Yellow Green

Reduced cutting

voltage

Output Signal proportional to the cutting voltage, not

galvanically isolated, according to the following ratios:

1:50 (factory setting); 1:20; 1:21; 1:30; 1:40.

5 (-)

6 (+)

Black (-)

Red (+)

SHARK 75/M - SHARK 105/M

CNC Female 14 pole connector

Vd Green wire

Nr Black wire

Rs Red wire

Bc White wire

GV Yellow / green wire

If the cutting bench’s guides and transmission system are

cleaned, checked and optimised, the torch moves easily. Un-

steady movement of the machine can give rise to an undulat-

ing, irregular path on the cutting surface.

Make sure that the torch does not touch the plate while cut-

ting. Contact could damage the shield and nozzle, and affect

the cut surface.

Having connected to the torch to the X-Y-Z bench, screw it to

the centralised connection on the SHARK system generator.

The two-pole cable that sticks out about 2 m from the central-

ised connection for the SKM plasma torch, is in series with the

start cut button.

Depending on the type of X-Y-Z bench and the software used,

the two-pole cable can be used as:

•

An additional emergency stopping unit for the mechanised

cutting machine.

•

A short-circuit for the 2 wires of the two-pole cable, if used as

an emergency stopping unit.

INTERFACE WITH A CNC CONTROLLER PLANT

The special SHARK 75/M and SHARK 105/M plasma versions,

are already complete with an interface for CNC controller equip-

ments, such as X-Y-Z cutting benches, for example.

On the front of the SHARK 75/M and SHARK 105/M machine

there is a 14-pole female connector (CPC TE Connectivity se-

ries) for connecting the CNC interface cable.

This socket makes the following signals available:

•

Arc voltage reduced to 1:50 (factory setting), with a maximum

output of 15 V (NOT galvanically isolated signal). Inside the

SHARK machine there is a dip-switch that can be used to

set other reduced arc voltages:

1:20 1:21 1:30 1:40

• Arc transfer / start machine movement signal

• Start cut signal.

The machine interface cable must be installed by a technician

from an authorised service centre.

To install the machine’s interface cable:

• Disconnect the power supply to the machine, by shifting the

switch to the O position.

•

Connect the machine’s interface cable to the 14-pole CNC

controller socket located on the front panel of the SHARK

75/M and SHARK 105/M machines. The male 14-pole in-

terface connector (CPC TE Connectivity series) is available

from our Company, using order code 460180.

FEMALE 14-POLE MACHINE INTERFACE

CONNECTOR OUTPUTS

On the front of the SHARK 75/M and SHARK 105/M machine

there is a 14-pole female connector (CPC TE Connectivity se-

ries) for connecting a CNC controller cable or a height con-

troller.

The signals available on the machine interface connector, are

indicated in figure N.

Loading...

Loading...