16

VOLTAGE DIVIDER SETTINGS

The secondary voltage divider is set in the factory at a value

of 1:50.

Inside the machine there is a dip-switch (SW1) that can be used

to set 4 other secondary voltage values:

1:20 1:21 1:30 1:40

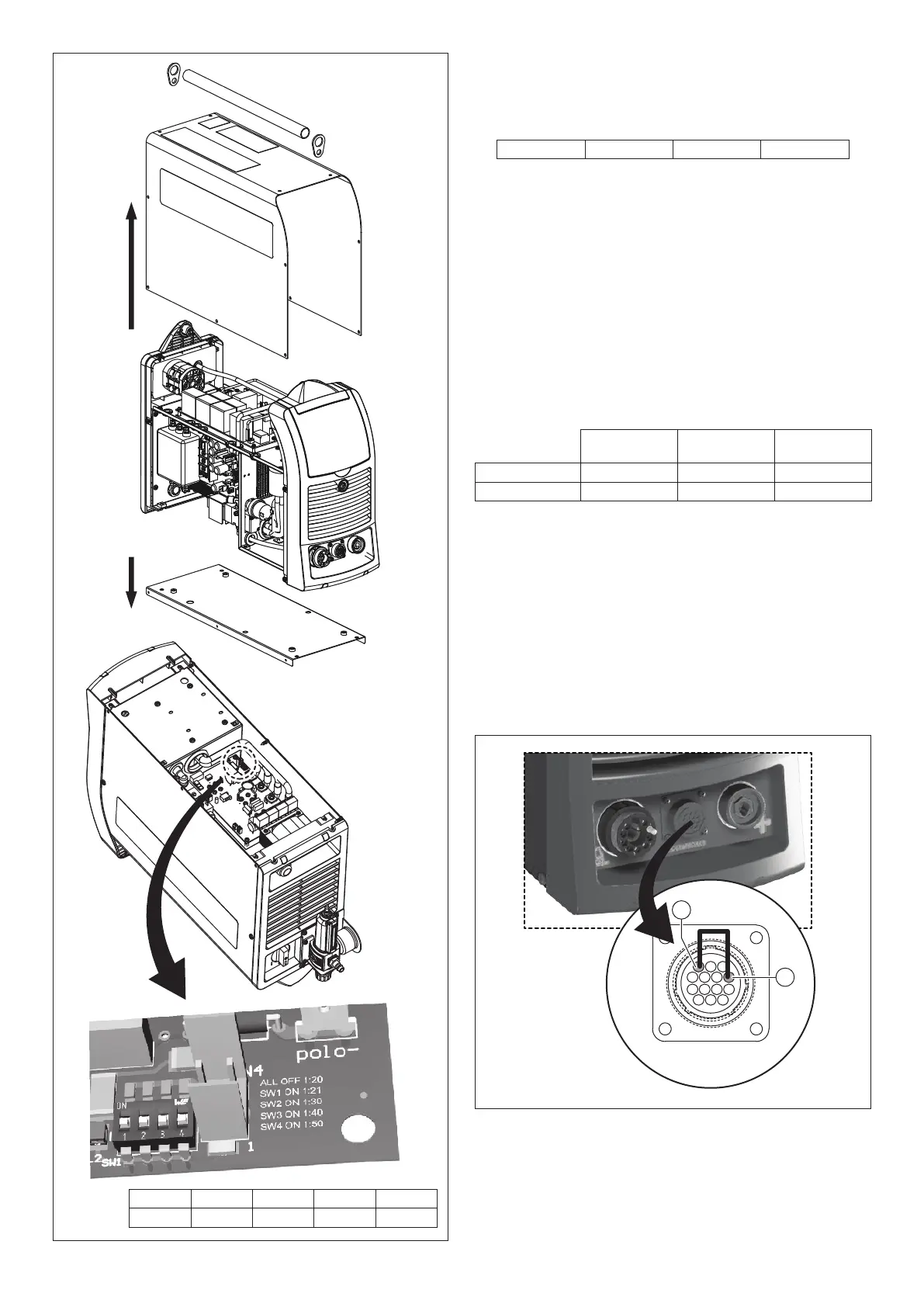

To access the dip-switch (SW1) proceed as follows (Fig. O):

1) Disconnect the power supply from the system by turning

the line switch on the back panel to the O position. Discon-

nect the machine’s power supply cable from the main pow-

er supply socket in the wall.

2) Remove the machine’s metal bottom plate to access the

machine’s secondary board.

3) Set the dip-switch (SW1) to one of the configurations avail-

able.

4) Reassemble the machine, following the points above in re-

verse order.

USING THE MANUAL PLASMA TORCH ON PLASMA

SHARK, “M” VERSION PLANTS

Manual torches can be used on SHARK “M” version plasma

plants for automatic plants as well:

Automatic

cutting torch

Manual torch Length

SHARK 75/M SKM 75 SK 75 6-12 m

SHARK 105/M SKM 125 SK 125 6-12 m

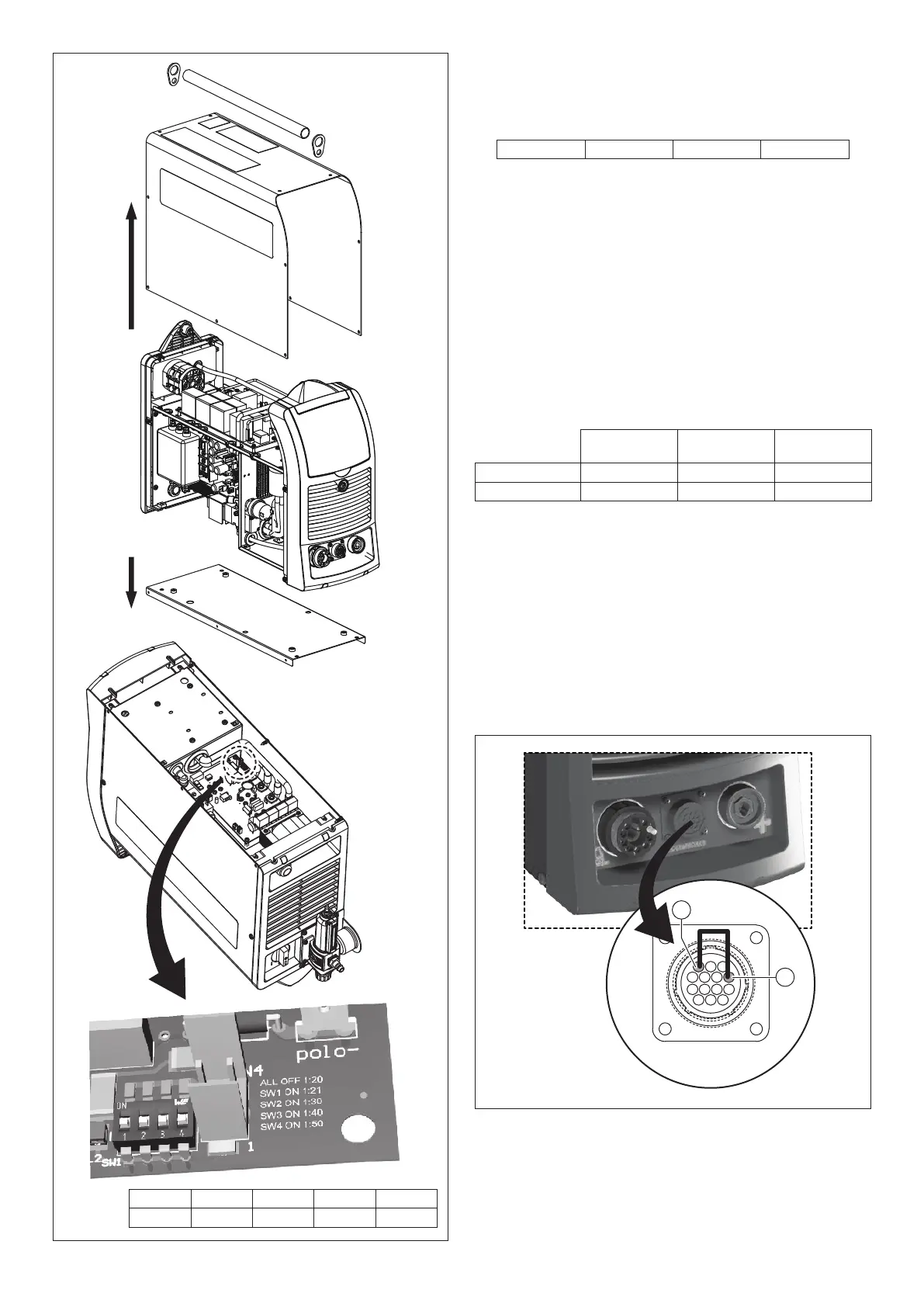

The manual torches can work in SHARK “M” version plants only

if terminals 3 and 4 are short-circuited on the 14 pole male con-

nector used to interface with the CNC controller plants (Fig. P).

Code 460180: buying code for the 14 pole male connector used

to interface with CNC controller plants.

4

3

FIG. P

FIG. O

ALL OFF SW1 ON SW2 ON SW3 ON SW4 ON

1:20 1:21 1:30 1:40 1:50

Loading...

Loading...