42

A more advanced search can be done for any faults, by access-

ing the front rack board and examining the diagnostic LEDs

provided.

The purpose of this board is to allow the operator to regulate

and interact with the machine, and determines all the functions

necessary for it to function, and for the cut to be executed.

The operator interface is in the form of a membrane keyboard

on the front panel, which included diagnostic / functional LED’s

for the machine, and the operating buttons for selecting the cut-

ting mode and activating the air flow test.

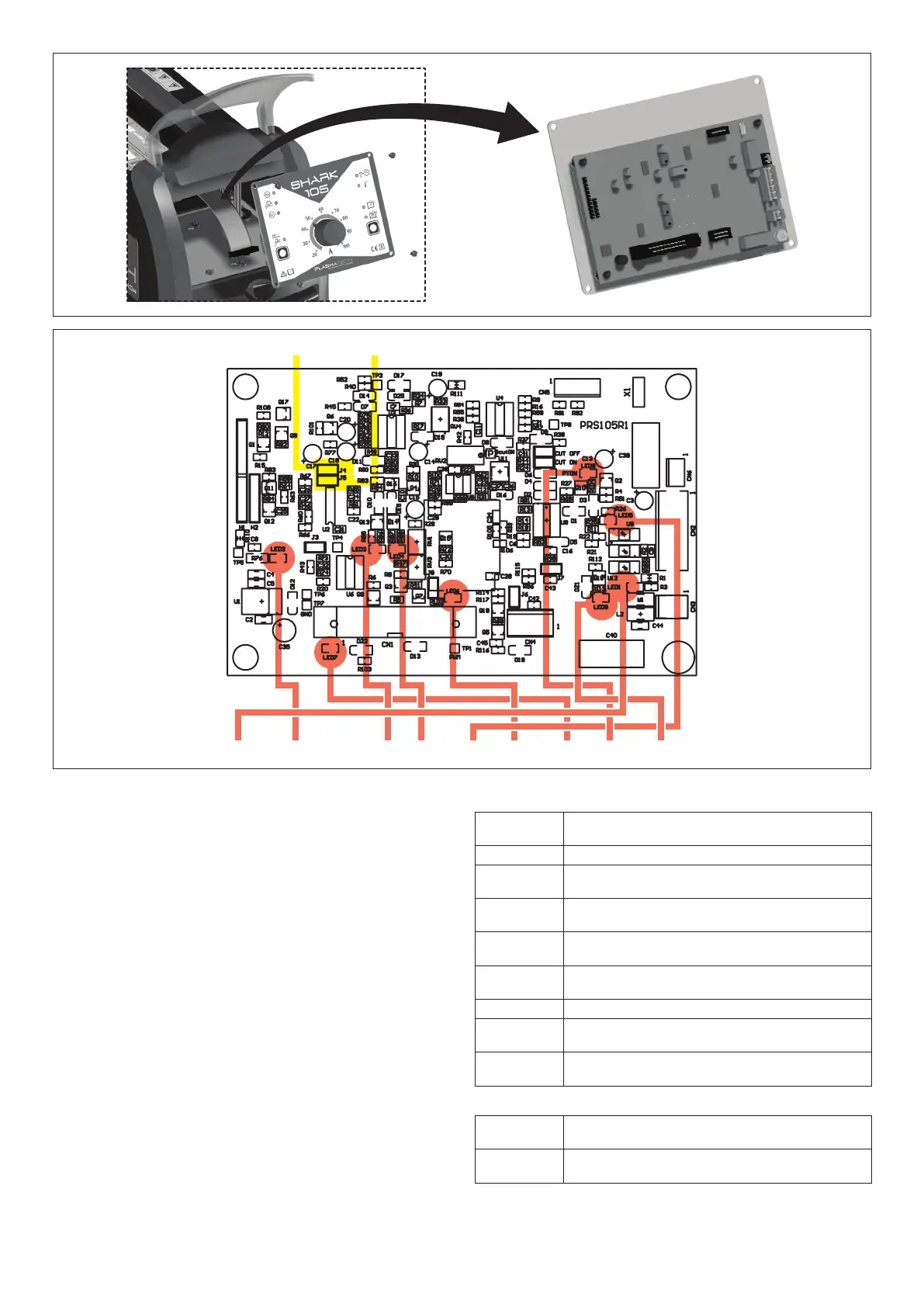

To be able to access the control board, proceed as follows

(Fig. S):

• Unscrew the 4 screws that fix the front rack panel.

•

The control board is fixed to the front rack, removed previ-

ously.

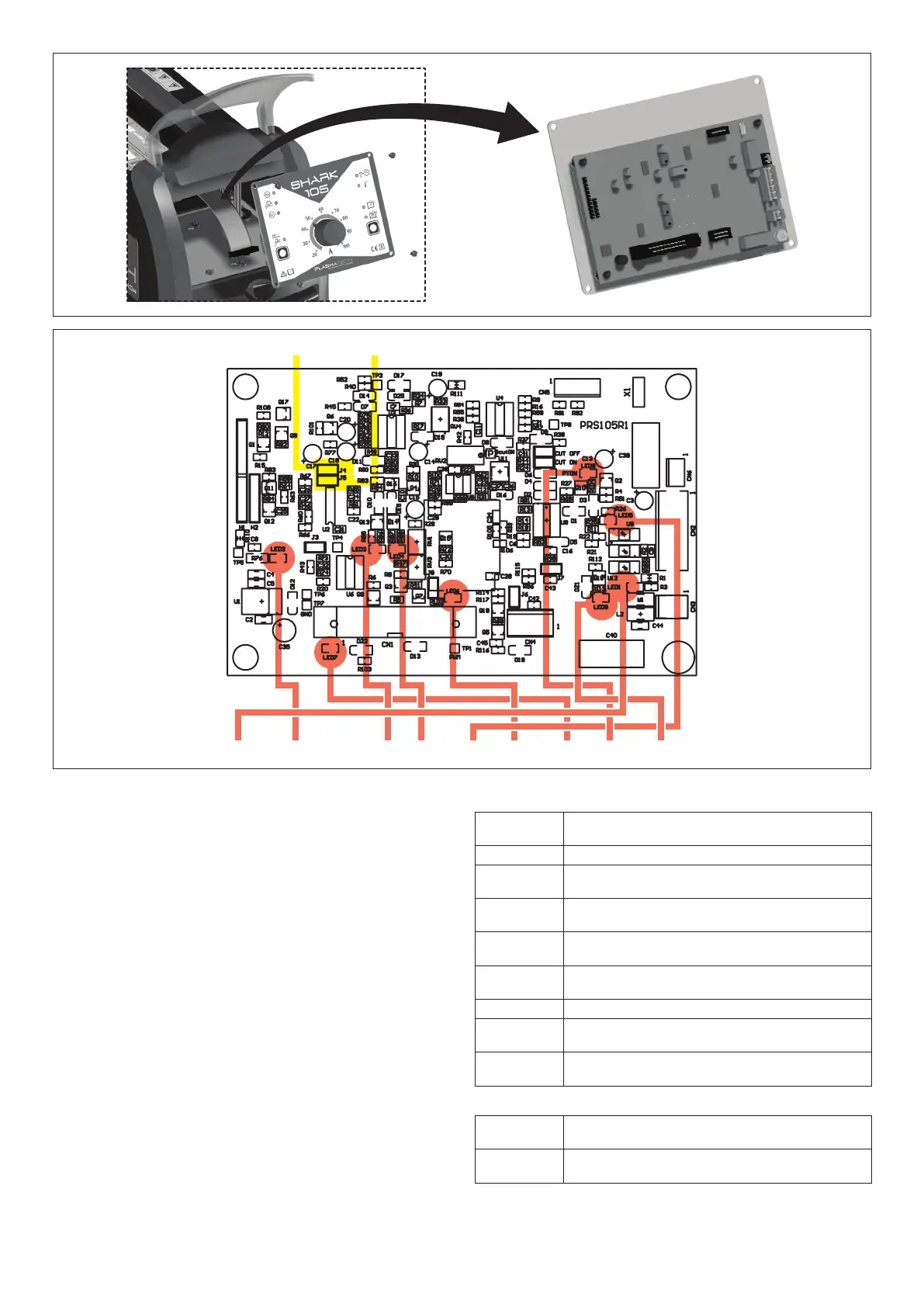

Figure T shows the layout of the front control rack board, high-

lighting the diagnostic LEDs and main trimmers fitted.

FIG. S

List of LEDs

LED1 Green LED, on when the TORCH BUTTON is

pushed.

LED2 Green LED, on when the +24 voltage is on.

LED3

Green LED, on when the inverter board is in an

OVER VOLTAGE state.

LED4 Green LED, on when the inverter board is in an

UNDER VOLTAGE state.

LED5 Green LED, one when the ARC TRANSFERRED

signal is active.

LED6 Green LED, on when the air solenoid valve is

activated.

LED7 Green LED, on when the fan is switched on.

LED8 Green LED, on when the torch button signal is

recognised by the board.

LED9 Green LED, on when the safety optical unit

PT(U12) is switched off (PT OFF).

List of JUMPERS

JP1 When inserted, on switching on the machine will

be in SOLID CUT mode.

JP2 When inserted, on switching on the machine will

be in MESH CUT mode.

J4 J5

LED1 LED2 LED3 LED4 LED5 LED6 LED7 LED8 LED9

FIG. T

Loading...

Loading...