9 Fusion data Operating instructions SG 160

42

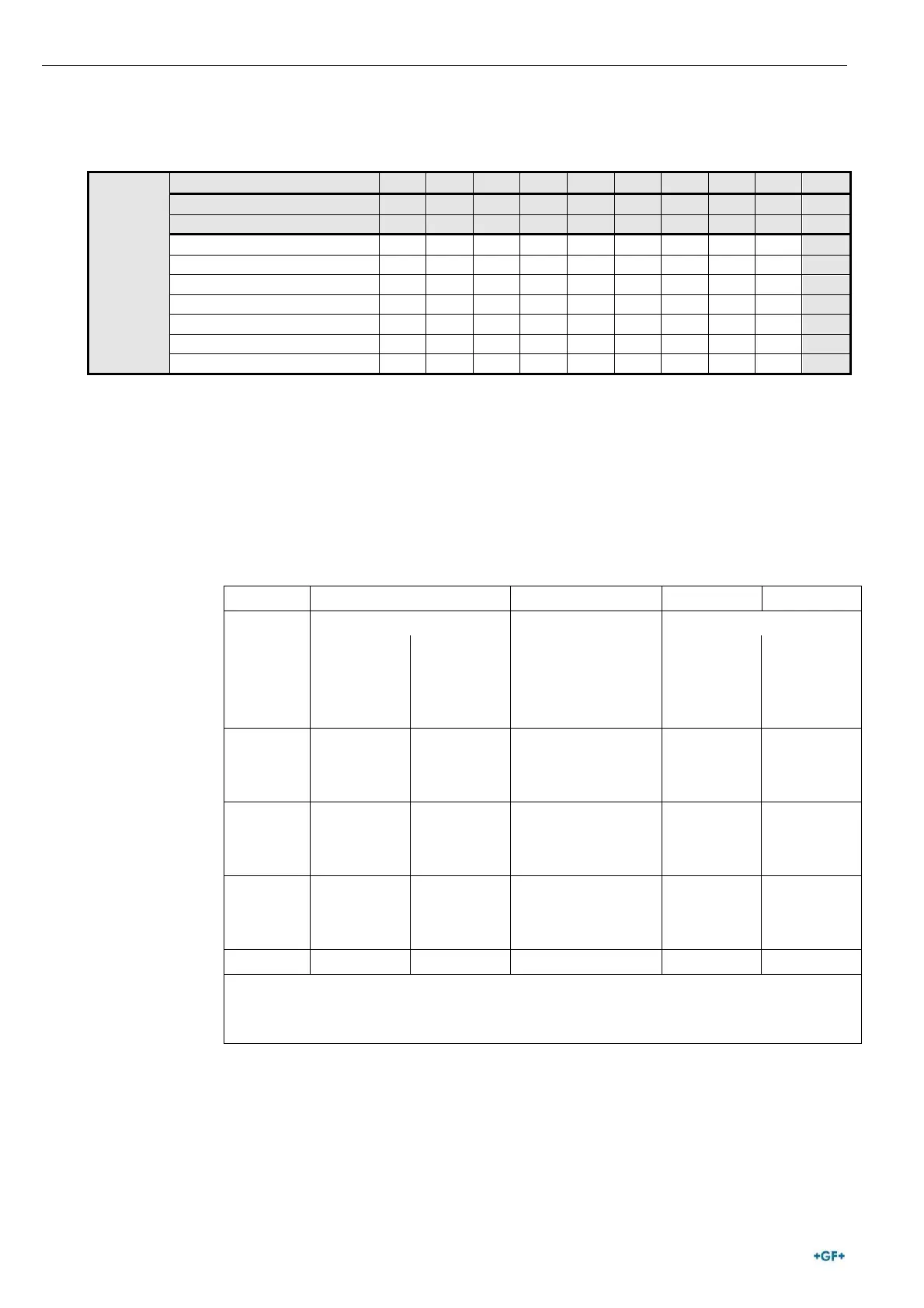

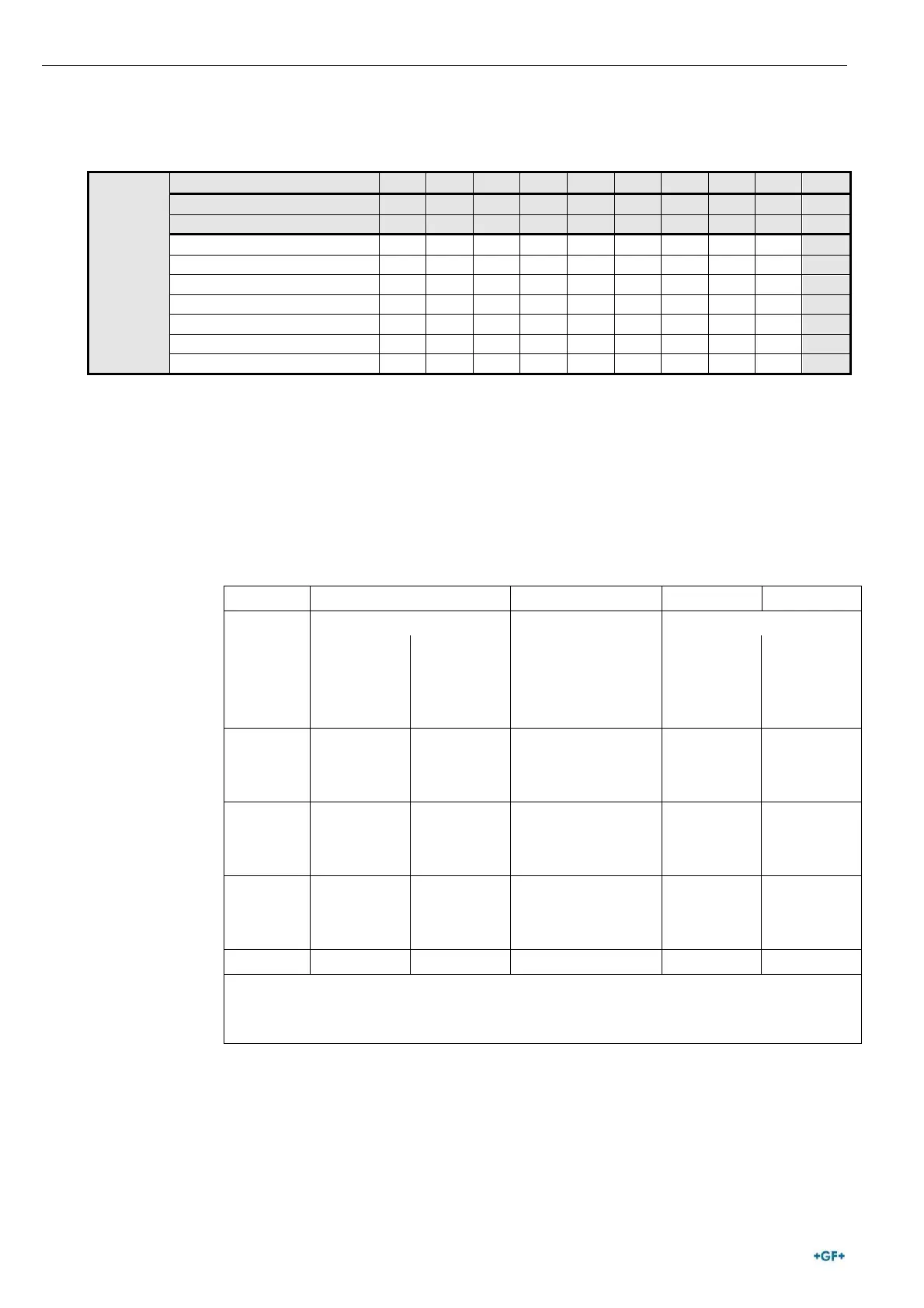

S 3.2

SDR 7.4

t4: Pressure buildup time

Guidelines for heating element socket fusion of pipes and piping

components in PE-HD

at an ambient temperature of 20 °C and

moderate air movement.

Heater temperature 260 °C ±

±±

± 10 °C

outer

diameter

SDR 11

2)

s

SDR

17,666

2)

s

s

s

min

d in mm

16 5 4 6 2

20 5 4 6 2

25 7

4 10 2

32 8

6 10 4

40 12

6 20 4

50 12

6 20 4

63 24

8 30 6

75 30 15 8 30 6

90 40 22 8 40 6

110 50 30 10 50 8

Due to small wall thickness, fusion is not advisable.

Standard Dimension Ratio = d/s (d= pipe outer diameter, s= pipe wall

thickness)

Loading...

Loading...