Operating instructions SG 160 9 Fusion data

43

Heating element butt fusion of PP

Fusion chart according to DVS 2207-11

Heating element temperature 210 °C ± 10 °C

thickness

Bead height on the

heating element after

equalization time

(equalization at

0.10 N/mm

2

)

(heat soak

≈ 0.01 N/mm²)

Time until max

pressure reached

Cooling time at fusion

pressure

(p = 0.10 N/mm²

± 0.01)

(min.value)

(max. time)

(min.value)

up to 4.5 0.5 up to 135 5 6 6

4.5 – 7.0 0.5 135 – 175 5 – 6 6 – 7 6 – 12

7.0 – 12.0 1.0 175 – 245 6 – 7 7 – 11 12 – 20

12.0 – 19.0 1.0 245 – 330 7 – 9 11 – 17 20 – 30

19.0 – 26.0 1.5 330 – 400 9 – 11 17 – 22 30 – 40

26.0 – 37.0 2.0 400 – 485 11 – 14 22 – 32 40 – 55

37.0 – 50.0 2.5 485 – 560 14 – 17 32 – 43 55 – 70

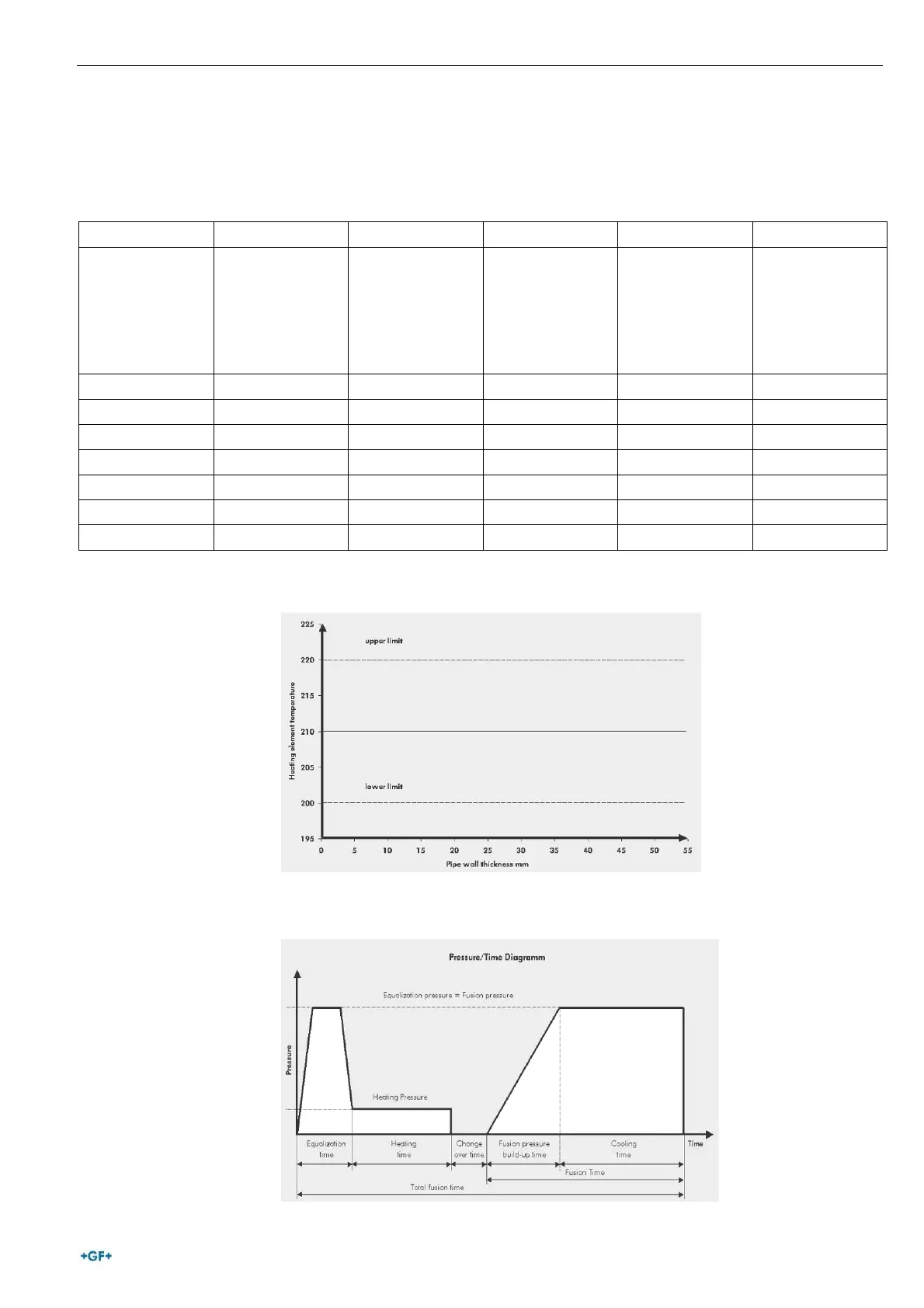

Diagram of standard values for heater temperatures in relation on pipe wall thickness

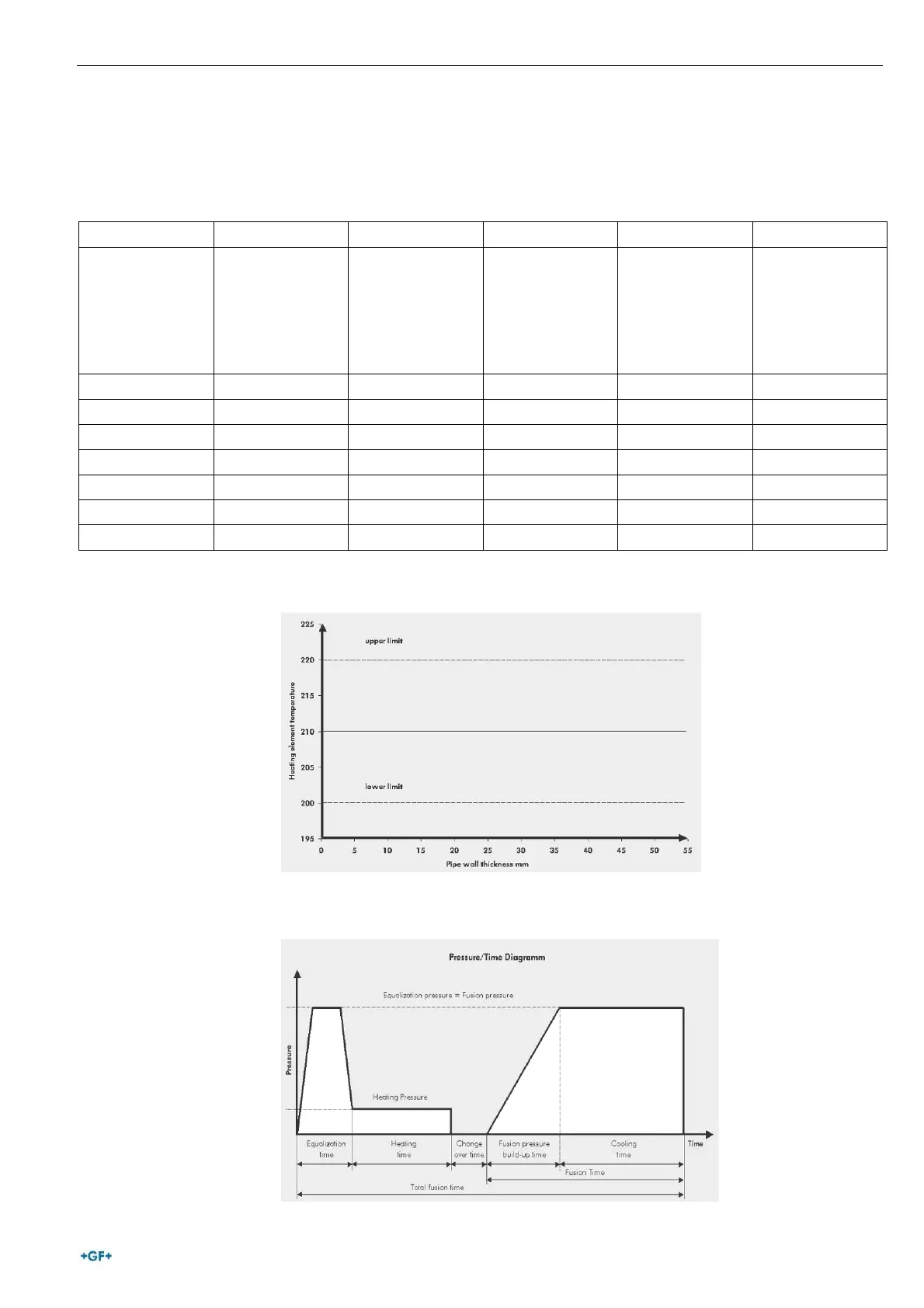

Process steps for heating element butt fusion

1 2 3 4 5

Loading...

Loading...