FUEL SYSTEM/CARBURETION

4.10

CARBURETOR INSPECTION

1. Inspect the inlet needle tapered surface for any

sign of wear or damage. Be sure the spring

loaded pin is free moving and returns freely when

pushed. The inlet needle and seat should be

pressure tested after assembly.

Good Condition

Worn, Deposits

Wear areas

Seat

Needle

CARBURETOR ASSEMBLY

Pilot Screw

1. Install the pilot mixture screw , spring, washer, and

O-ring as an assembly. Lubricate the O-Ring with

oil or light grease before installation. CAUTION:

Do not damage the O-ring during installation.

Turn t he screw in until it lightly contacts the seat.

Back out the specified number of turns. NOTE:

The final pilot (idle) mixture must be adjusted with

the engine running. Refer to Page 2.15.

Pilot Mixture Screw Base Setting

(Set at Factory)

Refer to Specifications in Chapter 1

FLOAT HEIGHT

ADJUSTMENT

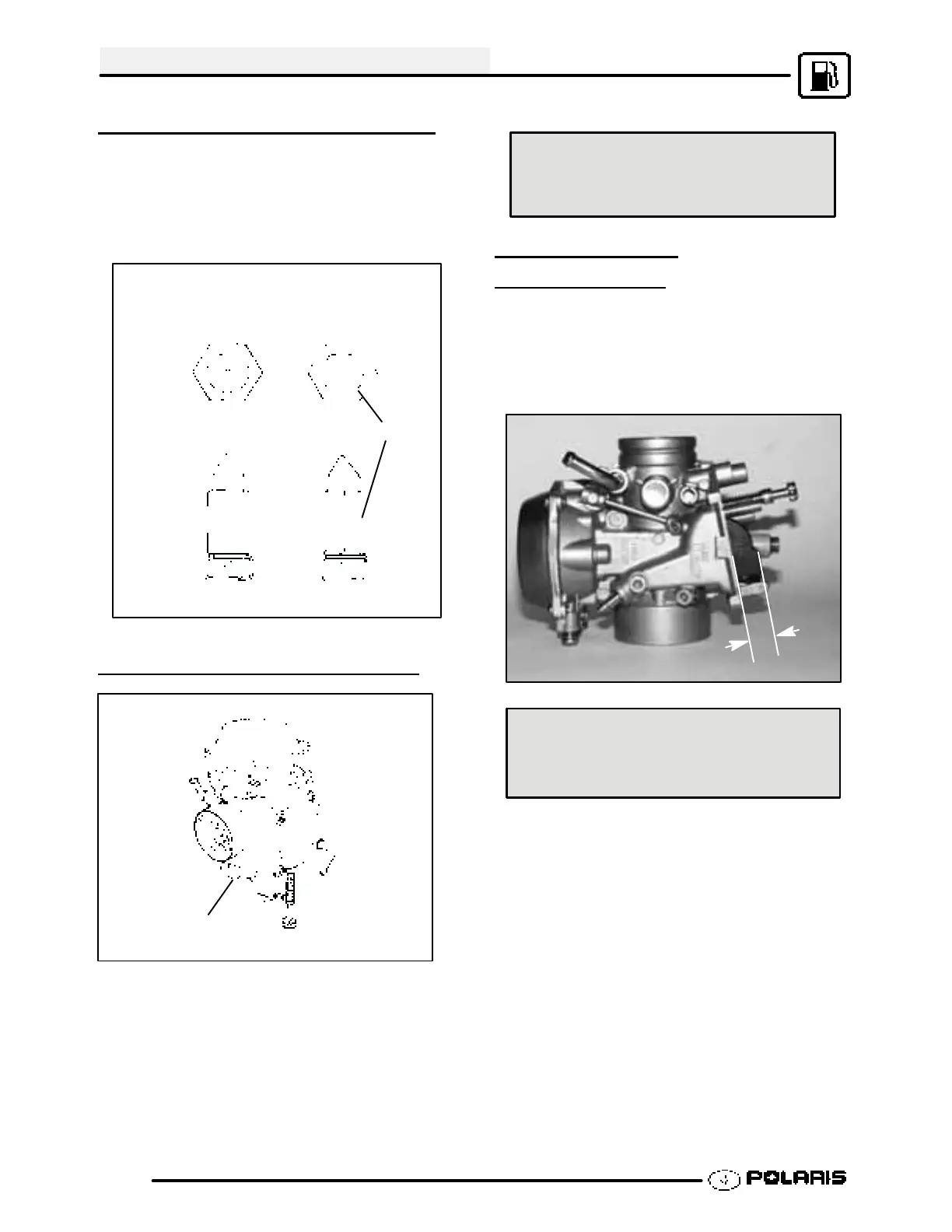

1. Place the carburetor on a level surface as shown

at right to remove weight from float arm. In this

position, the float tongue will rest lightly on the

inlet needle valve pin without compressing the

spring.

Float Height:

Std: BST 34 13--14 mm (.51--.55 inches)

2. Measure the height from the float bowl mating

surface to the top of step in float as shown. Both

sides of float should be parallel to each other. The

measurement should be made at the mid-point on

the top of the float using Float Adjustment Tool

(PN 2872314) or a vernier caliper. When

measuring the height be sure the inlet needle

valve spring is not compressed.

Loading...

Loading...