5. Place shop rags under the filter to catch any spilled oil during removal. Using

the your hand, or an Oil Filter Wrench, turn the oil filter counter-clockwise

until oil starts to drain through the slot in the skid plate. Allow the oil to stop

draining before removing the filter completely. Tip the open end of the oil filter

up to minimize oil spill. Ensure all shop rags are removed after cleaning up

any spilled oil.

6. Clean the filter sealing surface on the engine crankcase with a clean rag and

ensure the original oil filter o-ring is not stuck to the crankcase.

7. Lubricate the o-ring on the new oil filter with a film of clean engine oil. Check

to make sure the o-ring is in good condition. Tighten to specification.

TORQUE

Oil Filter:

Turn by hand until filter O-ring contacts sealing surface, then turn an

additional 3/4 turn.

8. Inspect the sealing washer on the drain plug for burrs or nicks. Replace the

washer if it is damaged.

9. Reinstall the engine crankcase drain plug. Torque drain plug to specification.

TORQUE

Engine Oil Drain Plug:

12 ft-lbs (16 Nm)

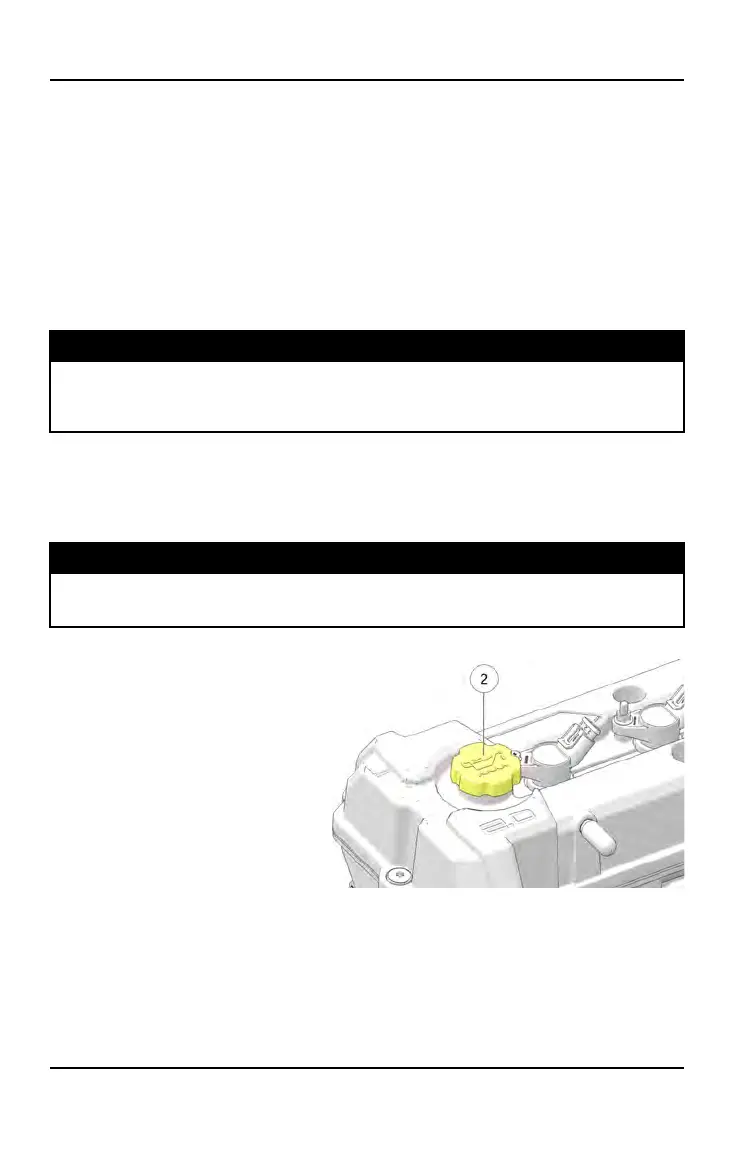

10. Remove the cargo box. Add

engine oil through the oil fill

cap

w

located on top of the

engine valve cover.

11. Fill the engine to the

recommended specification.

See the Specifications

chapter.

12. Start engine and allow it to

idle for two-to-three (2-3)

minutes.

13. Stop the engine and inspect for leaks. Wait at least three (3) minutes before

removing the oil dipstick.

94

MAINTENANCE

Loading...

Loading...