CUSTOM

AIR

CONDITIONING

1A-17

placed Is of great importance. Any attempt to use

COMPRESSOR

REAR

HEAD

ASSEMBLY

makeshift

or inadequate equipment may result In

damage and/or improper operation of compressor.

REMOVE

PRESERVATION

AND

PACKING

SERVICE

PARTS

All

parts required for servicing

will

be protected

by

a preservation

process

and packaged in a manner

which

will

eliminate the necessity of cleaning, wash-

ing

or

flushing

of the parts. The parts can be used

in

the mechanism assembly just as they are re-

moved

from

the service package.

In

addition, some parts

will

be

Identified

on the

piece part to denote its size or dimension. This

will

apply to the piston

shoe

discs and the shaft

thrust

races.

To

provide suitable and

adequate

quantities and

grouping

of parts for servicing the compressor,

kits

are available

which

will

contain

these

neces-

sary parts. The gasket kit should be used whenever

it

is

necessary

to overhaul or

rebuild

entire com-

pressor internal mechanism, or when replacing some

individual

internal part.

OVERHAUL

COMPRESSOR

Anytime

a major overhaul or

rebuilding

opera-

tion

is to be performed on this compressor, obtain

and

install

compressor gasket kit. This kit includes

all

of the

necessary

O-rings and gaskets. Obtain

also, an ample supply of piston rings.

1. Remove compressor oil

plug,

tilt

compressor

and drain oil

Into

clean dry container. It may be

possible to get

only

4 to 6 ozs. of oil

from

the

compressor at this

time.

2.

Attach

J 9396

holding

fixture

to compressor and

mount

in vise.

3.

Remove compressor

pressure

relief

valve.

4.

Remove

four

lock

nuts

from

threaded

studs

welded

to compressor shell and remove rear head.

NOTE:

Some oil may

drain

when the head is

removed.

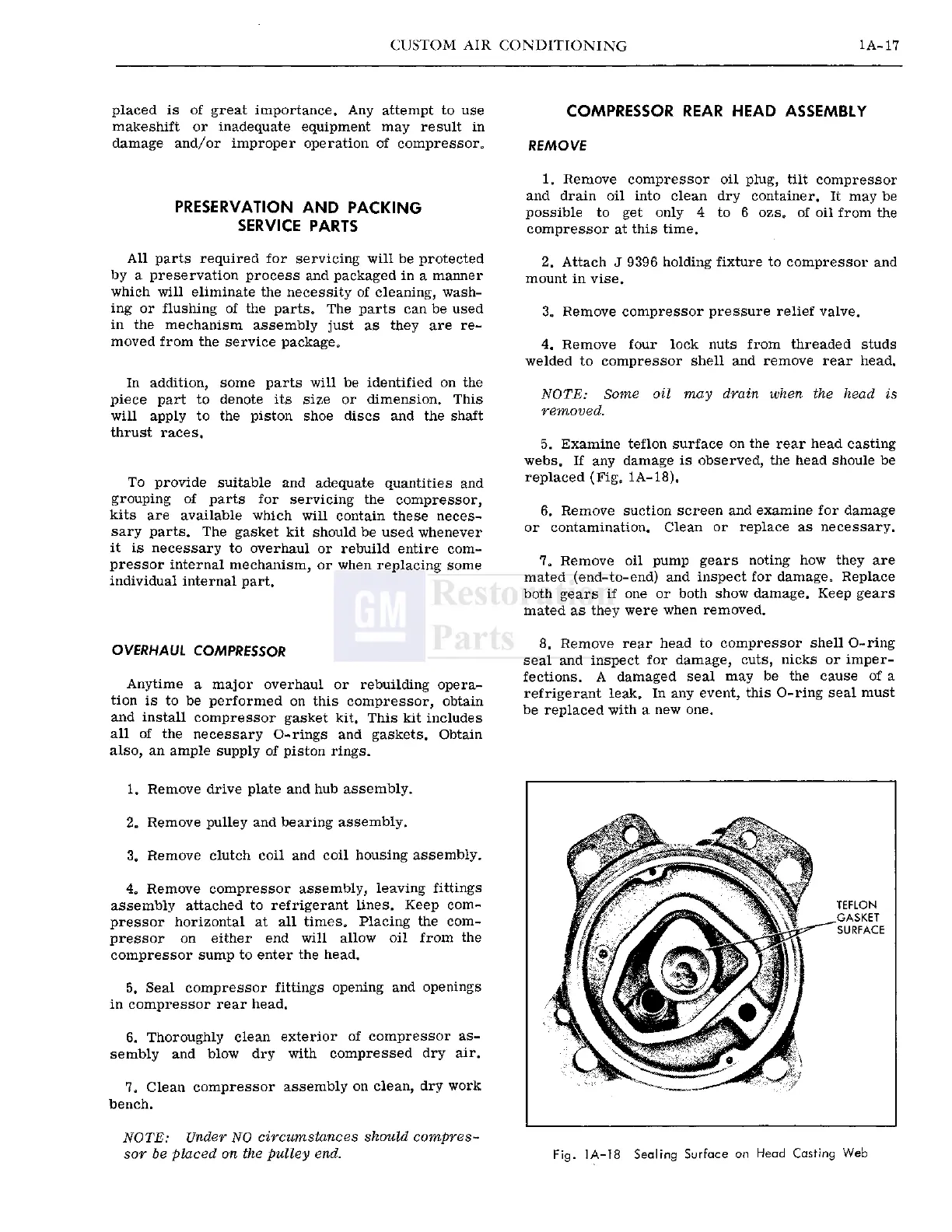

5. Examine

teflon

surface on the rear head casting

webs. If any damage Is observed, the head shoule be

replaced (Fig, 1A-18).

6. Remove suction screen and examine for damage

or

contamination. Clean or replace as

necessary.

7. Remove oil pump

gears

noting how they are

mated (end-to-end) and inspect for damage. Replace

both

gears

if one or both show damage. Keep

gears

mated as they were when removed.

8. Remove rear head to compressor shell

O-ring

seal and inspect for damage, cuts, nicks or imper-

fections.

A damaged seal may be the

cause

of a

refrigerant

leak. In any event, this

O-ring

seal must

be replaced

with

a new one.

1. Remove drive plate and hub assembly.

2.

Remove

pulley

and bearing assembly.

3.

Remove

clutch

coil

and

coil

housing assembly.

4. Remove compressor assembly, leaving

fittings

assembly attached to refrigerant lines. Keep com-

pressor horizontal at all times. Placing the com-

pressor on either end

will

allow

oil

from

the

compressor sump to enter the head.

TEFLON

^GASKET

SURFACE

5. Seal compressor

fittings

opening and openings

in

compressor rear head.

6. Thoroughly clean exterior of compressor as-

sembly

and

blow

dry

with

compressed dry air.

7. Clean compressor assembly on clean, dry

work

bench.

NOTE:

Under NO circumstances should compres-

sor be placed on the

pulley

end.

Fig.

1A-18

Sealing

Surface

on

Head

Casting

Web

Loading...

Loading...