10

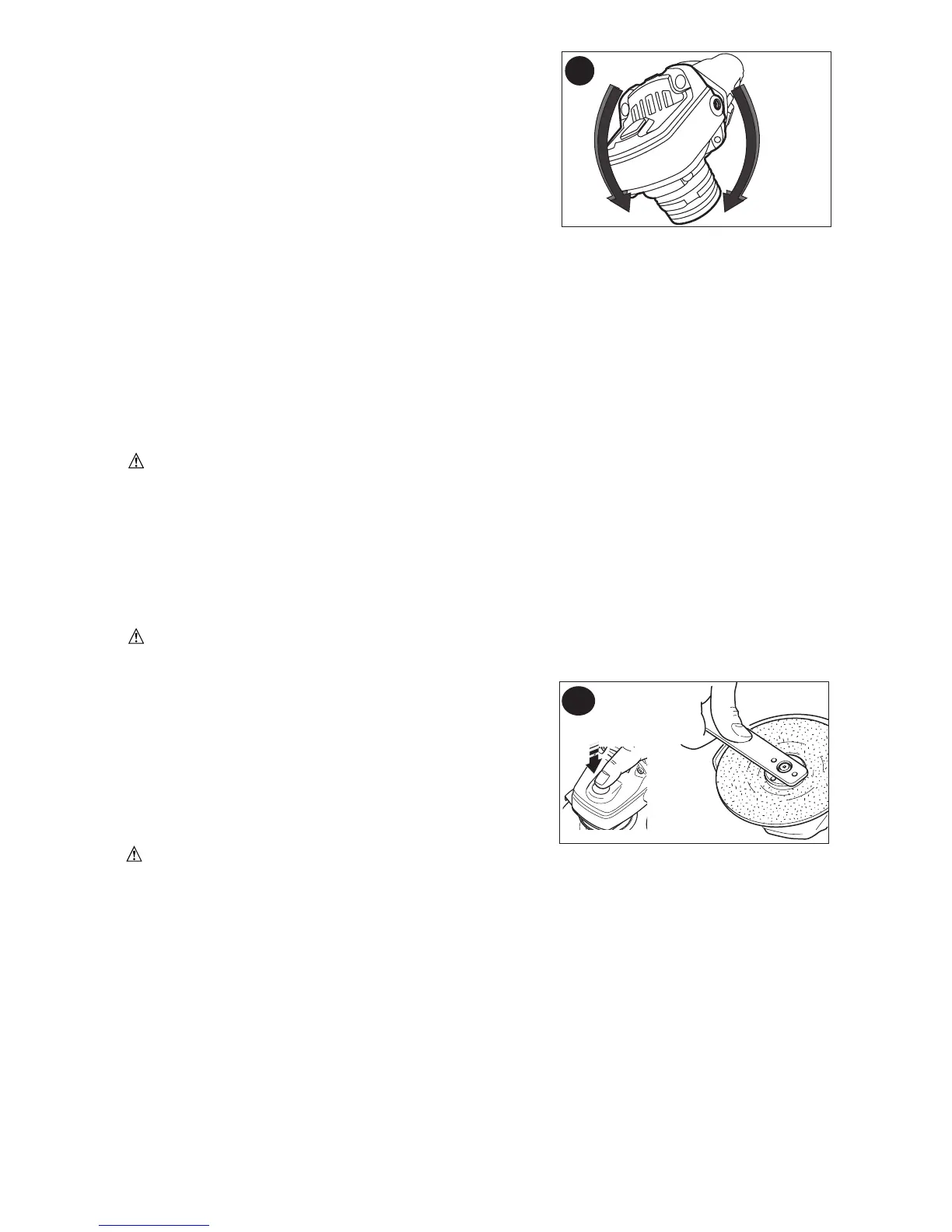

ROTATING THE GEAR CASE (FIG. E)

Turn off and unplug tool before making any

adjustments or removing or installing accessories.

Before reconnecting the tool, depress and release the

trigger switch to ensure that the tool is off.

1. Remove guard and flanges from tool.

2. Remove the four corner screws attaching the gear

case to motor housing.

3. Separating the gear case from motor housing not

more than 1/4 in., rotate the gear case head to

desired position.

NOTE: If the gear case and motor housing become separated by more than 1/4 in., the

tool must be serviced and re-assembled by a Porter Cable service center. Failure to

have the tool serviced may cause brush, motor and bearing failure.

4. Re-install screws to attach the gear case to the motor housing.

Tighten screws to 18 in./lbs. torque. Overtightening could cause screws to strip.

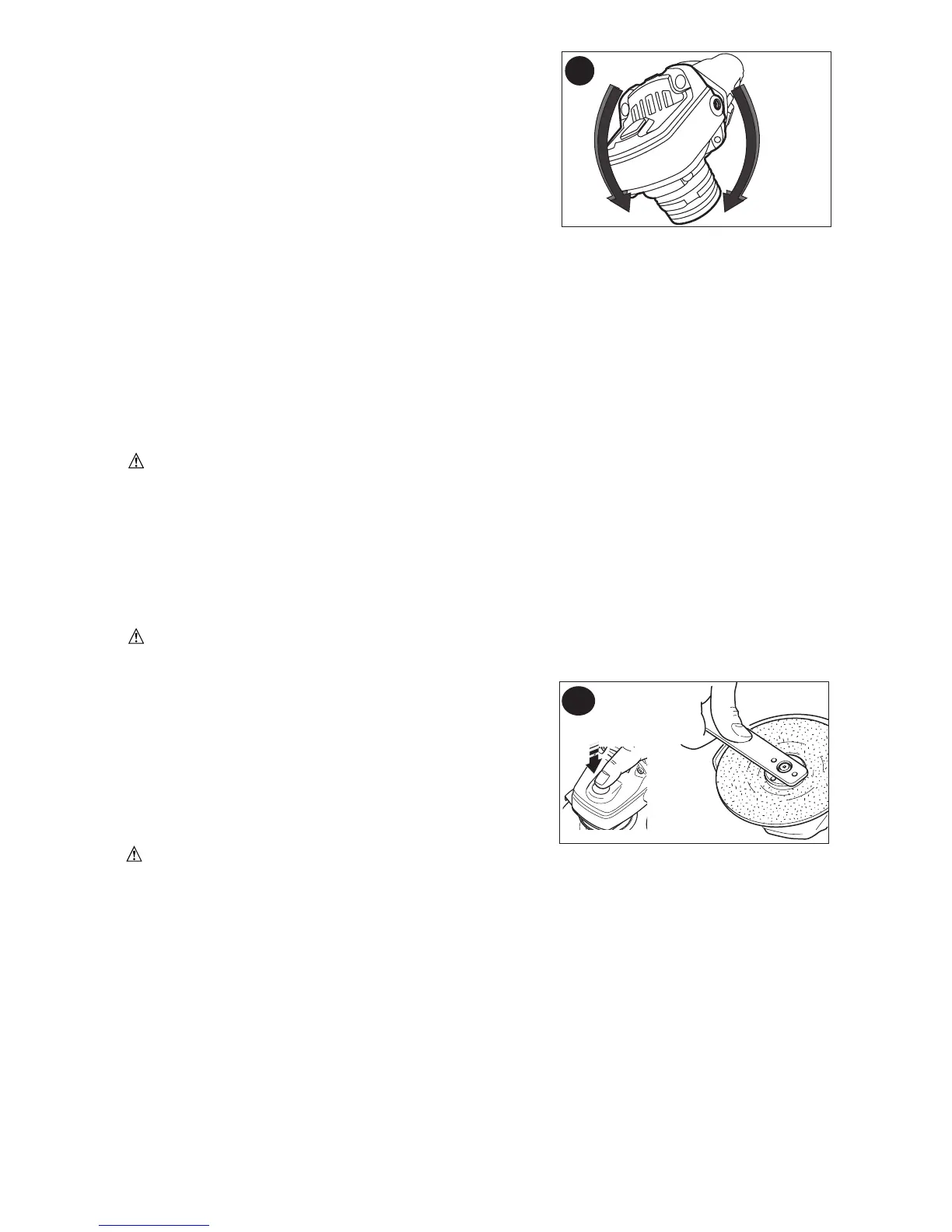

SPINDLE LOCK

The spindle lock button (6) is provided to prevent the spindle from rotating when installing

or removing wheels. Operate the spindle lock only when the tool is turned off and the

wheel has come to a complete stop.

WARNING: Do not engage the spindle lock while the tool is operating. Damage

to the tool will result and attached accessory may spin off possibly resulting in injury.

To engage the lock, depress the spindle lock button shown in figure E1 and rotate the

spindle until you are unable to rotate the spindle further.

MOUNTING AND USING DEPRESSED CENTER GRINDING WHEELS AND

SANDING FLAP DISCS

Mounting and Removing Hubbed Wheels

WARNING: To prevent accidental operation, turn off and unplug tool before

performing the following operations. Failure to do this could result in serious

personal injury.

Hubbed wheels install directly on the 5/8 in.-11

threaded spindle.

1. Thread the wheel on the spindle by hand.

2. Depress the spindle lock button and use a wrench

(figure E1) to tighten the hub of the wheel.

3. Reverse the above procedure to remove the

wheel.

CAUTION: Failure to properly seat the wheel

before turning the tool on may result in damage to the tool or the wheel.

E

90

o

90

o

E1

Loading...

Loading...