15

EVD-2 • 5401042 • REV L • 03/05

SENSITIVITY ADJUSTMENTS

1. Adjust the EVD-M’s internal pickup sensitivity control, RV1, to 1/2 scale (12 o’clock

position). Refer to Figure 1 for adjustment location.

2. If remote pickups are installed, adjust the EVD-M’s remote pickup network

sensitivity control, RV2, to the minimum setting listed in Table 2. If no EVD-R’s are

installed, adjust RV2 to the minimum setting, fully counter-clockwise. Refer to

Figure 1 for adjustment location.

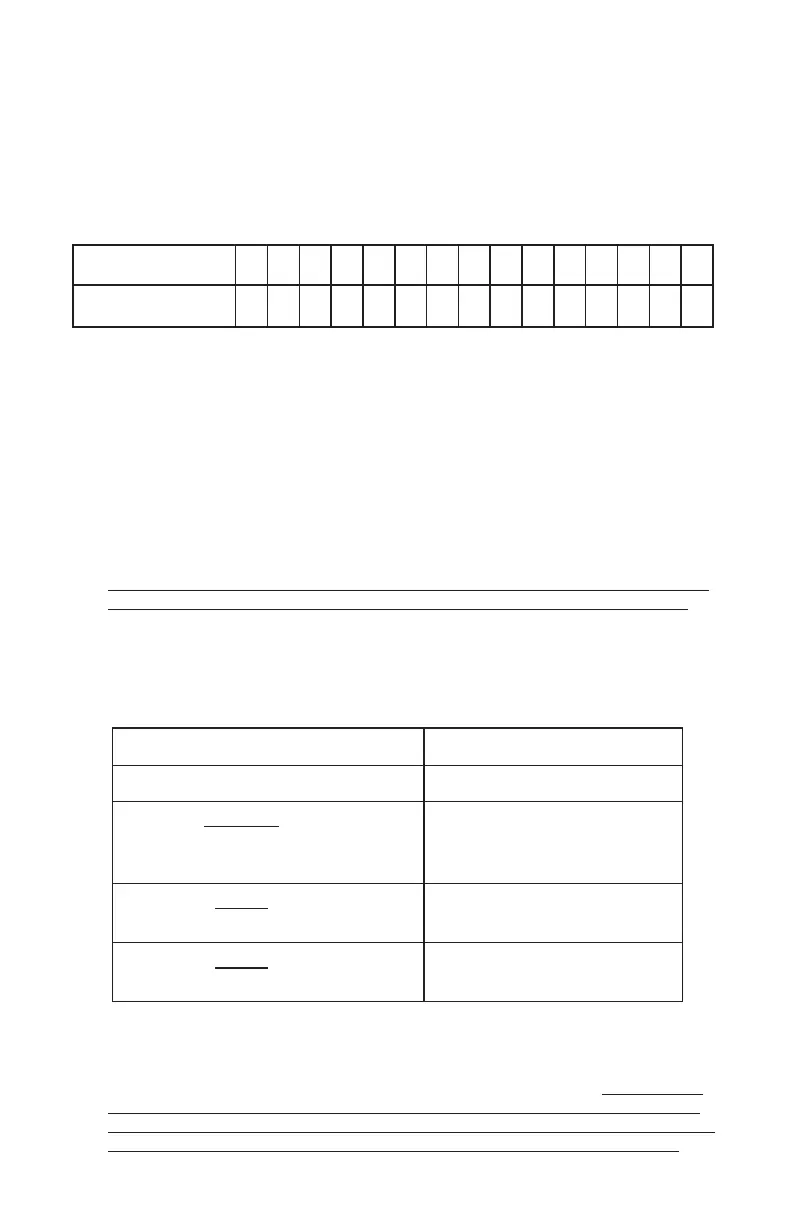

Table 2.

spukciPetomeRforebmuN 123456789 011121314151

krowteNetomeRmuminiM

gnitteSytivitisneS

000 4/14/14/14/14/12/12/12/12/12/14/34/3

3. Adjust accumulator rotary switch, S1, to desired setting. A setting of zero disables

the accumulator function. Refer to Figure 1 for adjustment location.

4. Perform simulated attack tests on all accessible surfaces that are protected by the

EVD-M and EVD-R’s. Strike the protected surfaces using a plastic mallet or the

plastic handle of a large screwdriver. An alarm condition (as indicated by the

status LED turning RED) must occur. Lightly scrape the blade of a screwdriver

next to the EVD-M and each EVD-R. After 15 seconds of continuous scraping,

an alarm condition (as indicated by the status LED turning RED) must occur. Be

sure the scraping generates a test point voltage greater than the

minimum constant noise level shown in Table 3. Adjust sensitivity settings

to the minimum needed to achieve desired level of response.

NOTE: Extreme care should be exercised so that the protected surfaces

are not marred or damaged while performing simulated attack tests.

A voltmeter can be connected to the analog test point and pin 2 of the field wiring

terminal block to aid the installer in adjusting the sensitivity controls. Refer to

Figure 1 for analog test point location.

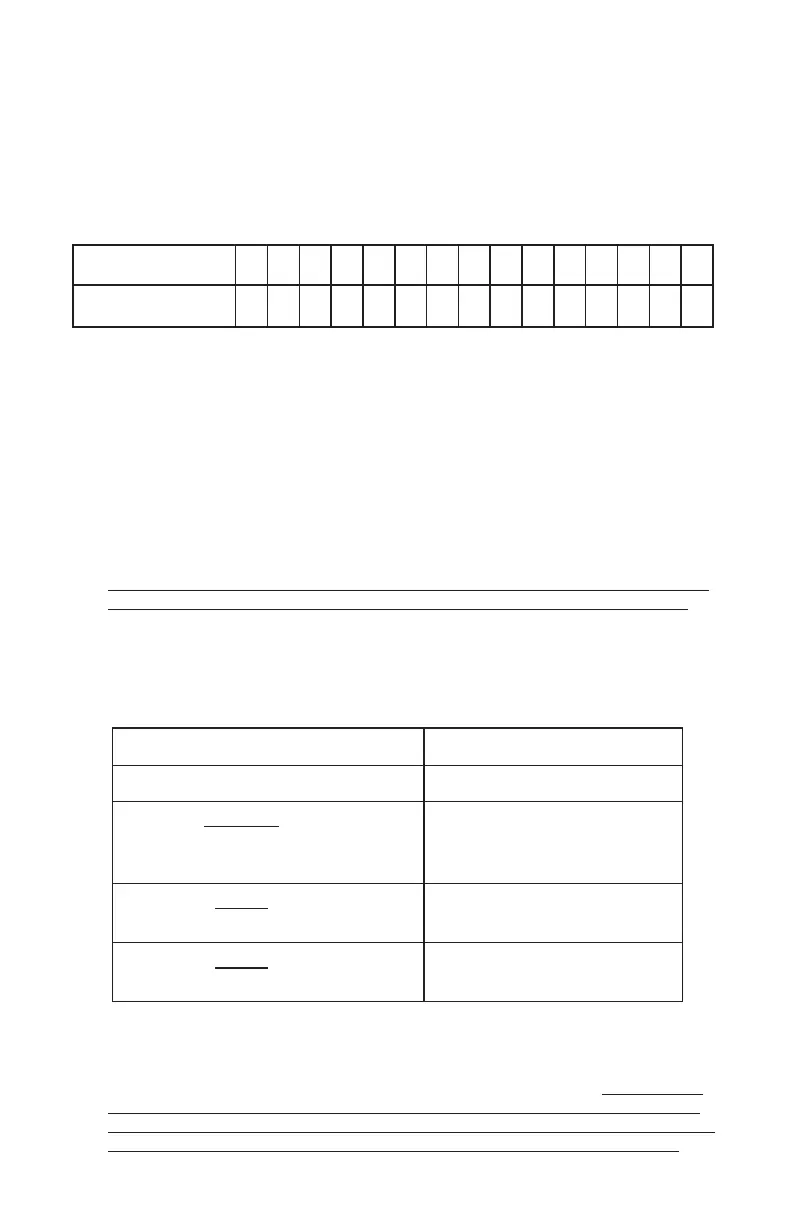

Table 3. ANALOG TEST POINT LEVELS

noitpircseDlangiSleveLtnioPtseTgolanA

leveLesioNtneibmAmumixaMCDV02.0

muminiMtnatsnoC

mralArofesioN

)gnillirDtpecxe(

)noitarud.ces51.nim(

CDV52.0

muminiMelgniS

mralArofesioN

)nOrotalumuccA(

CDV07.0

muminiMelgniS

mralArofesioN

)ffOrotalumuccA(

CDV52.1

5. With the system operating in a non-alarm state, verify the operation of all tampers.

A tamper condition is indicated by the status LED turning AMBER. If the system

is in alarm when a tamper condition occurs, the status LED will remain

RED, identifying the alarm condition. The tamper alarm remote annuncia-

tor and the tamper alarm contact always identify a tamper condition.

Loading...

Loading...