LIMIT ADJUSTMENT PROCEDURE

▲ WARNING: READ ENTIRE PROCEDURE BEFORE

STARTING. TURN OFF MAIN POWER BEFORE MAKING

ANY ADJUSTMENTS!

▲ WARNING: STAY CLEAR OF ALL MOVING PARTS AND

ELECTRICAL COMPONENTS OF THE OPERATOR WHILE

TESTING!

A CONTROL STATION SUCH AS A THREE BUTTON

STATION (“OPEN”,”CLOSE”,“STOP”) WITH ALL

NORMALLY OPEN CONTACTS IS REQUIRED FOR THIS

PROCEDURE. SEE INSTRUCTIONS BELOW.

456

7

OPEN

CLOSE

STOP

COMMON

1. Connect a wire from the common connection of the

control station to terminal #5.

2. Connect a second wire from the “OPEN” button of

the control station to terminal #6.

3. Connect a third wire from the “CLOSE” button of the

control station to terminal #7.

4. Connect a fourth wire from the “STOP” button of the

control station to terminal #4.

24

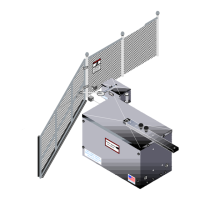

NOTE: Operator should be completely installed,

mechanically and electrically, before attempting to

set limit switch cams (See Fig. 11).

NOTE: For master slave installation, travel time for

the master operator must be set longer than the

slave operator.

OPEN LIMIT SWITCH ADJUSTMENT:

Figure 11

ADJUSTMENT

SET SCREW

LIMIT CAM

OPEN LIMIT CAM

CLOSE LIMIT CAM

DRIVE SHAFT

OPEN LIMIT SWITCH

CLOSE LIMIT SWITCH

LIMIT SWITCH

ACTUATING SCREW

1. Turn on power. Press open button on control station,

gate should stop before full open position is reached. If

gate does not stop when open position is reached,

PRESS STOP BUTTON!

2. To adjust gate for more open travel, loosen open limit

cam set screw and rotate limit cam, in the opposite

direction drive shaft rotates to open gate. Re-tighten set

screw after adjustment (See Fig. 11).

3. If it was necessary to stop gate, adjust open limit

switch cam for less open travel, by rotating the cam in

the same direction that the drive shaft rotates to open the

gate.

4. Press close button and stop gate in mid travel with

stop button.

5. Repeat procedure until desired open setting is

obtained.

Loading...

Loading...