page no. 38 of 68

LX Range Users, Installation & Servicing Instructions Doc Ref M110 issue 1.0 Dec 2020.

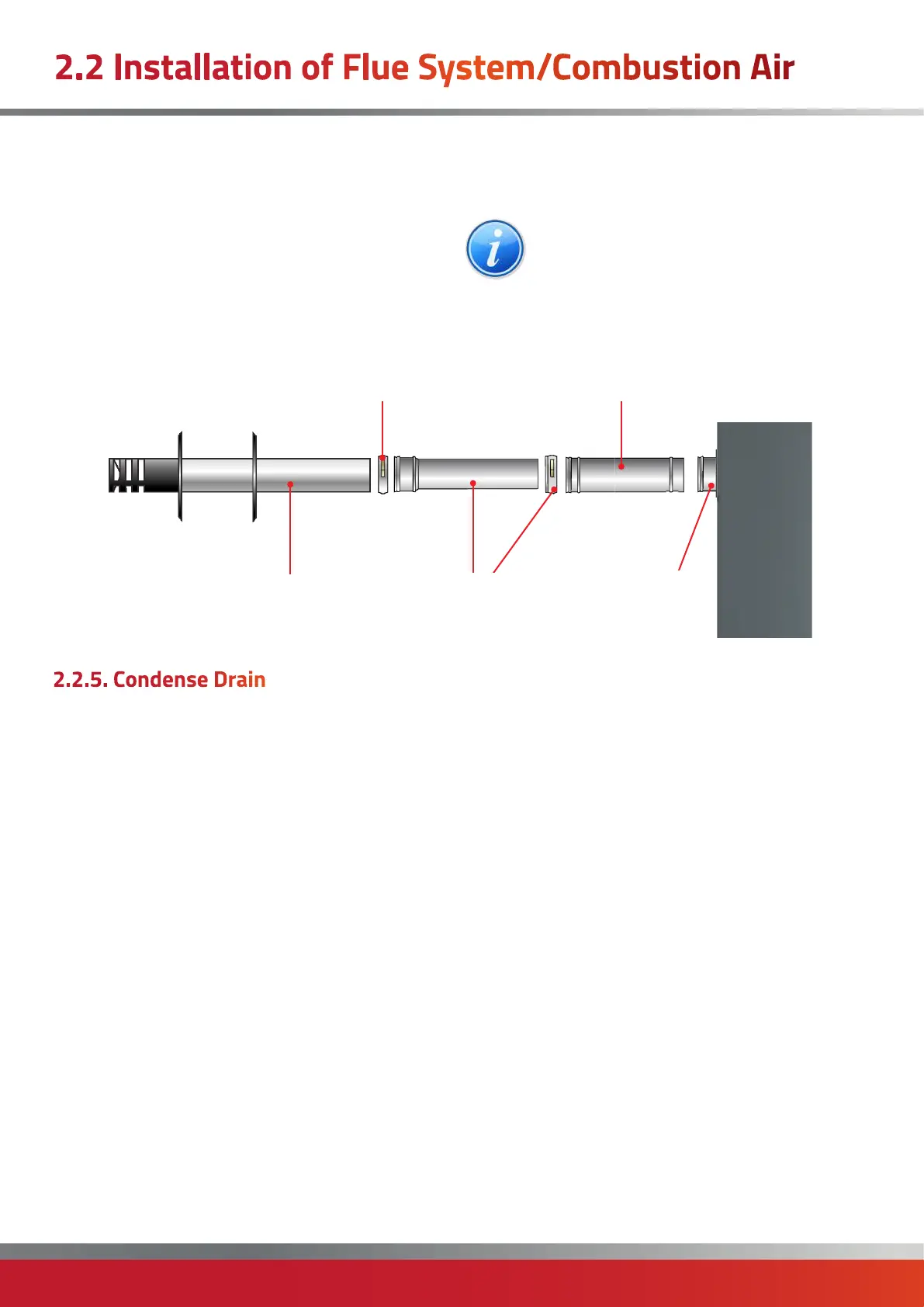

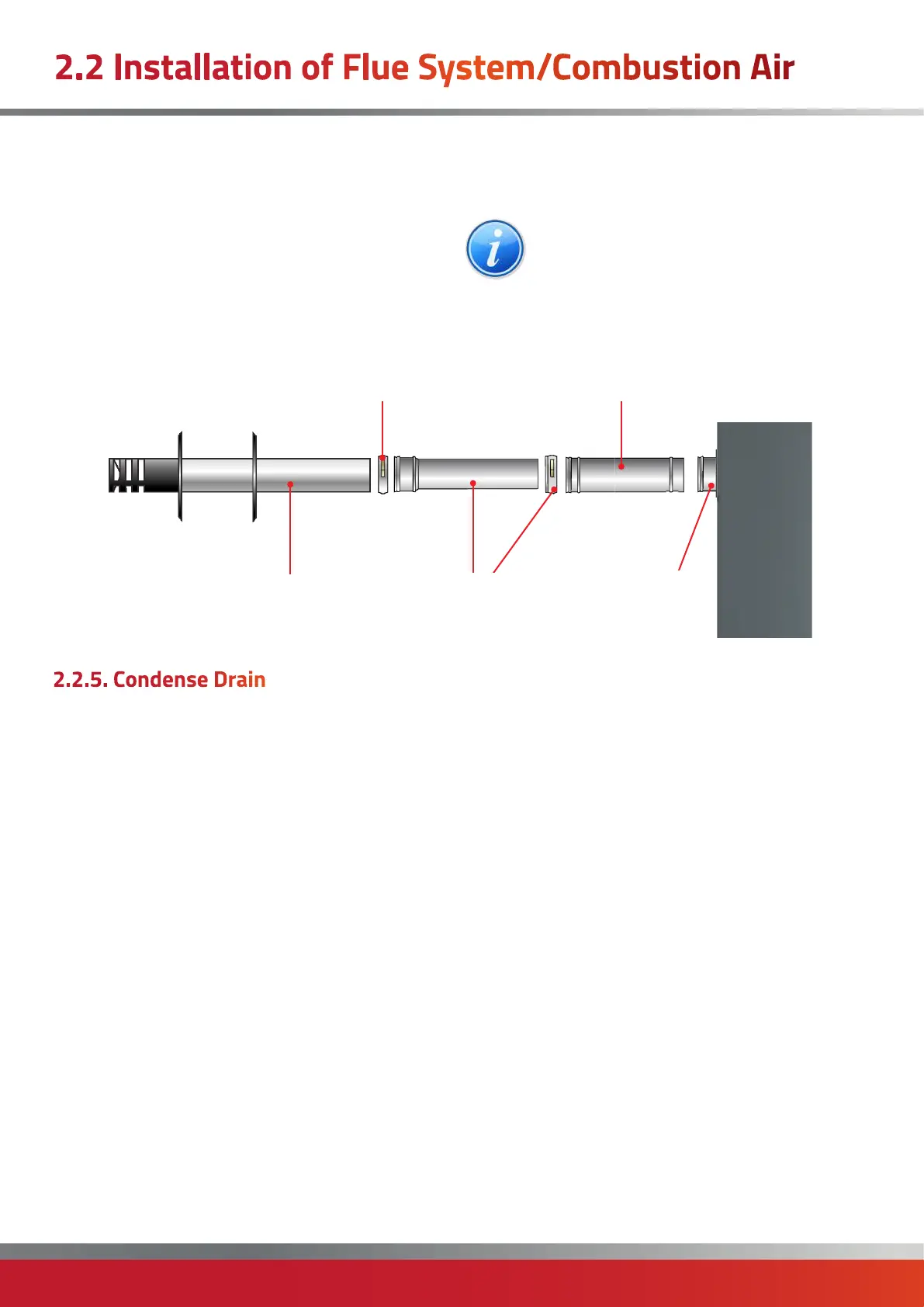

Extra lengths of standard flue can now be added between

the adjustable length and final flue connection. (not shown

on sketch below). Clamp with locking bands.

Prior to connection to the final piece of flue, place a locking

band onto the end of the flue pipe.

Clamp the flue locking band. (This locking band may be

very tight!, see section 2.2.3.1 for correct installation).

Heater

Horizontal Wall Terminal

Locking Band

Adjustable Length

c/w Locking Band

250mm Flue Length

Heater

Spigot

Typical Horizontal Single Flue

type B22 - exploded view

2.2.5. Condense Drain

We recommend installing a Powrmatic inline condense

flue drain when flued vertically, due to the lower flue gas

temperatures experienced when the heater is operating

at low firing rates. Other relevant factors include

installations where significant length of the flue is used

which may cause chilling, or if heater may be exposed to

high winds and heavy rain, which may ingress the flue.

Even if the drain point is capped, should the drain be

required in the future.

The trap and associated pipe work must be protected

from freezing. If drainage under gravity is not possible a

condensate pump should be used and installed following

the manufacturers instructions.

The condensate drainage pipe should be run in one of he

following materials PVC; PVC-U; ABS; PP or PVC-C and,

where necessary, have a fall of at least 2.5° in every 50m.

Any condense pipework must be adequate to prevent

sagging. A maximum spacing of 0.5m for horizontal and

1.0m for vertical sections should be adequate. Bends

should be kept to a minimum. Copper or copper based

alloy must not be used for condensate drains. See BS

6896; BS5440 and IGEM/UP/10.

Condensate may be piped and discharged to a number

of points within a building including:- internal stack pipe,

waste pipe, external drain or rainwater hopper provided

Once all flue components are correctly in place, lock the

adjustable length locking band back at the adjustable

length section.

NOTE: Refer to the following typical

breakdown sketch to aid with the above

procedures.

it is part of a combined system (i.e. sewer carries both

rainwater & foul water). Alternatively, the condensate

can be discharged into a purpose made soakaway. A

neutralizer must be used which is subject to a routine

replacement programme, in line with the manufacturers/

suppliers guidelines.

Where a drain point cannot be reached by gravity, a

suitable condensate pump can be considered. Pump

manufacturer's instructions must always be followed.

If the termination is to be to an external stack then in

addition to the requirements for connecting to an internal

stack, extra care is necessary in order to reduce the risk

of the drain becoming blocked due to the condensate

freezing. A length of pipe external to the building of not

less than 50mm diameter should be kept as short as

possible and not more than 3m. Any trap in the drainpipe

must be fitted within the building. In exposed locations

the pipe should be protected with waterproof pipe

insulation to prevent ice forming within the condensate

pipework.

Building regulations require a trap in the pipe whether it

is terminated directly to the outside or before it connects

to another waste pipe. If the drain pipe is taken directly to

a gully or rainwater hopper, a water seal of no less than

38mm is required. When connected to another waste pipe

the water seal must be at least 75mm, to prevent foul

smells entering the building.

2.2 Installation of Flue System/Combustion Air

Loading...

Loading...