10

Copyright © 2020 Quality Machine Tools, LLCPM-1440GT v9 2020-10

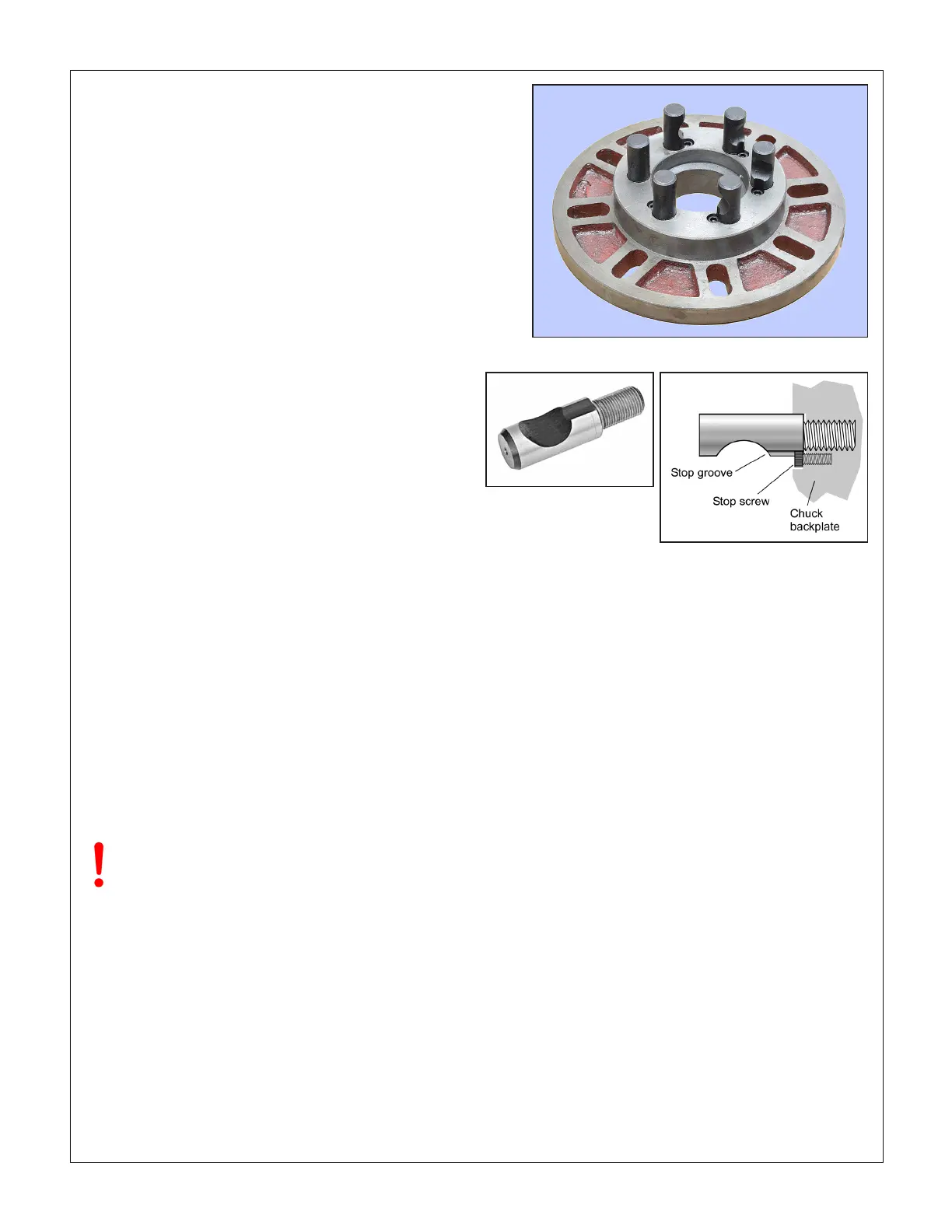

CHUCKS & FACEPLATE

The spindle nose on the PM-1440GT accepts D1-5 Camlock

chucks, faceplates and other work holding devices.

A D1-5 chuck or faceplate is held by six threaded studs, each

with a D-shape crosscut to engage a corresponding cam in

the spindle nose, Figures 3-4, 3-5. The function of the cams is

to pull the chuck backplate inward to locate its internal taper

rmly on the spindle nose.

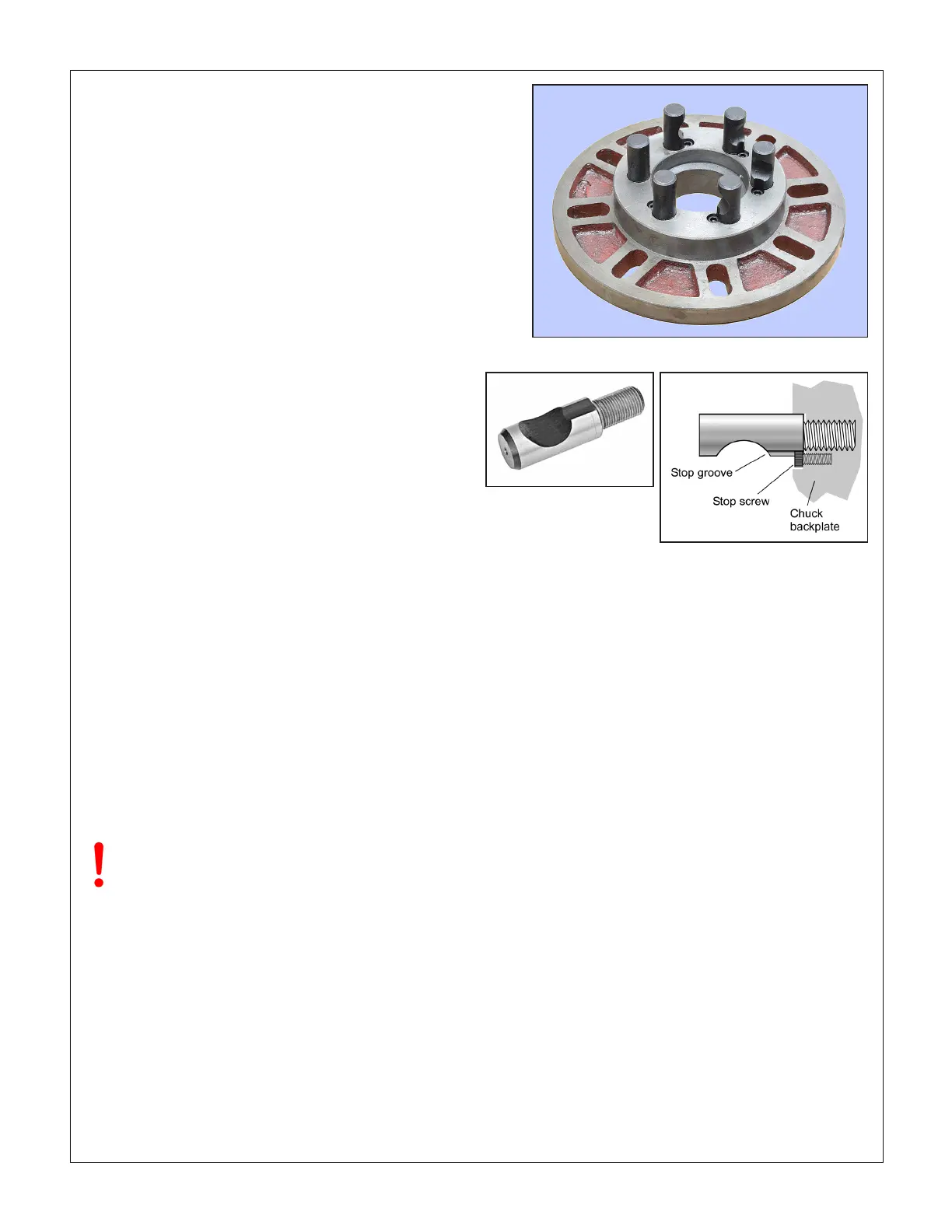

Alongside each stud is a stop screw, the head of which ts

closely in a groove at the threaded end of the stud. The func-

tion of the stop screw is not to clamp the stud in place, but

instead to prevent it from being unscrewed when the chuck is

out on the bench.

Figure 3-5 Camlock stud

TO INSTALL A CHUCK

Disconnect the 220V supply from the lathe!

D1-5 chucks and faceplates are heavy, some more than 30

lb. They will cause serious damage if allowed to fall. Even if a

chuck is light enough to be supported by one hand, the lathe

bed should be protected by a wood scrap, as Figure 3-6. Some

users add packing pieces, even custom-made cradles, to as-

sist “straight line” installation and removal.

Before installing make certain that the mating surfaces of the

chuck/faceplate and spindle are free of grit and chips.

The cams on the spindle are turned with a square-tip wrench

similar to the chuck key (may be same tool in some cases).

Recommended procedure:

1. Disconnect power from the machine. Then, select the high-

est spindle speed (2000 rpm) to allow easier hand rotation

of the spindle. (Alternatively, try moving the speed selec-

tion levers between detents to nd a “between teeth” con-

SADDLE FEED DIRECTION

The control knob with pointer below the speed selectors, Figure

3-1, determines whether the saddle feed is right to left — the

usual direction for turning and thread cutting — or reversed.

The selected direction applies to both the leadscrew and the

saddle/cross-slide power feed. Power feed is OFF when the

knob is at 12 o'clock position, as in the photo.

Before changing feed direction, STOP THE MOTOR. Hand-

turn (jiggle) the spindle while feeling for the mesh, as above.

To disengage the power feed, set the Saddle Feed lever to its

mid-position.

More information on the power feed system is provided later in

this Section, see Saddle Feed Gearbox.

Figure 3-4 D1-5 faceplate

All stop screws must be present & fully tightened!

Camlock action can jam any stud lacking a stop

screw — a serious problem.

JOG FEATURE

"Jog" is momentary-type push-button, active only if the Motor

Control lever is in the mid-travel (OFF) position, Figure 3-2.

Press the button briey to "nudge" the spindle forward by a

few degrees. Jog can be used to reposition the chuck and/or

workpiece, especially useful when low spindle-speed gearing

makes hand rotation dicult.

The control system can be rewired for "Reverse Jog", see the

electrical diagram, Section 5.

Loading...

Loading...