25

Copyright © 2020 Quality Machine Tools, LLCPM-1440GT v9 2020-10

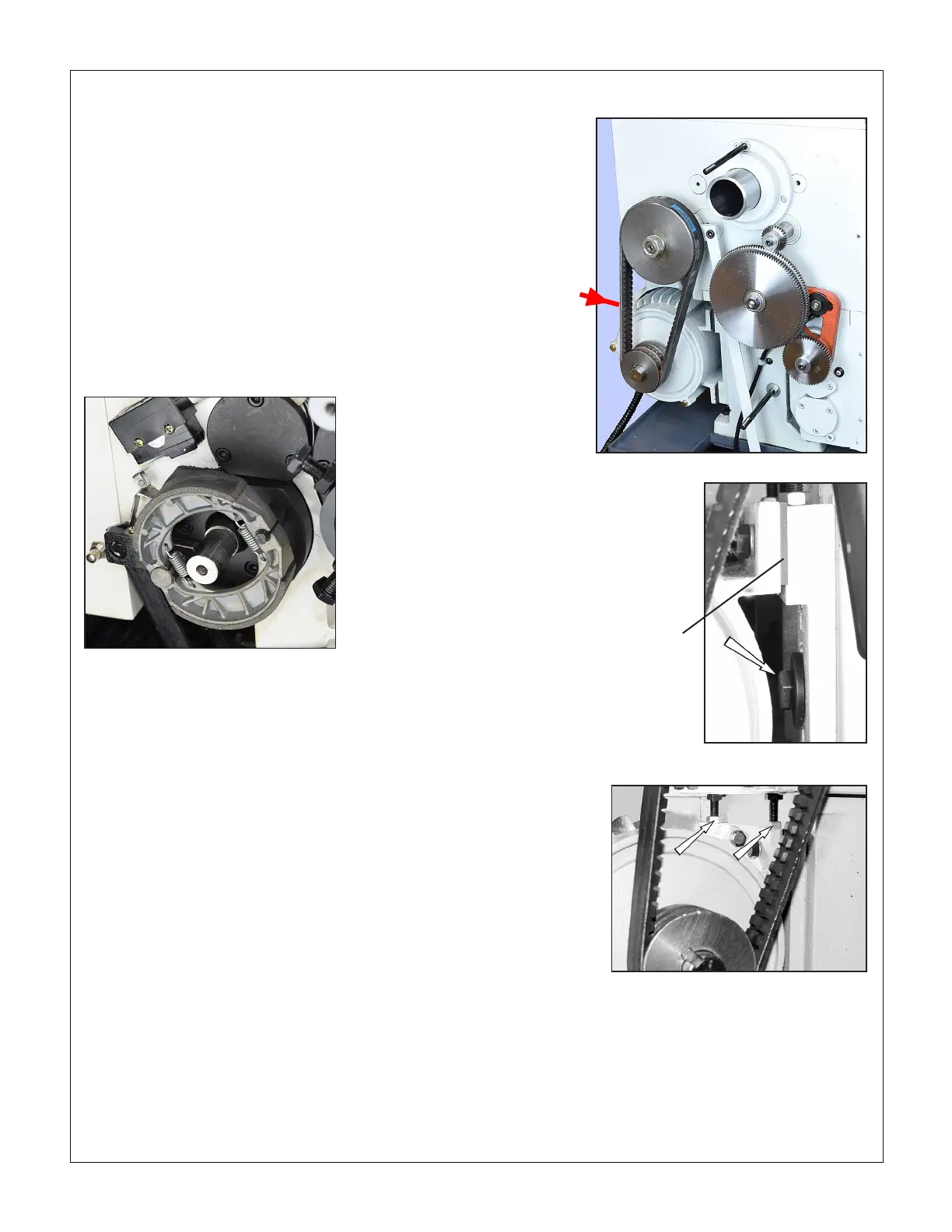

BRAKE ASSEMBLY

The treadle-operated brake does two things: 1. It disconnects

power from the motor, and; 2. It expands brake shoes against

the hollowed-out inboard face of the driven pulley.

Inspection of the brake assembly, Figure 4-16, calls for person

A to lock the driven pulley while person B removes the hex nut

securing the driven pulley.

The inboard face of the driven pulley (the brake drum) should

show no gouging or irregularities. Minor damage may be cor-

rectable by skimming; otherwise consider replacing the item.

The brake pads should be clean, evenly worn, showing no sign

of oil. Minimum pad thickness is 4.5 mm, about 0.18". If nec-

essary replace the pads by separating them — extending the

springs — then lifting them clear of the retaining studs.

Figure 4-16 Brake assembly (representative)

Firm nger

pressure here

should deect

the Vee belt

about 1/4"

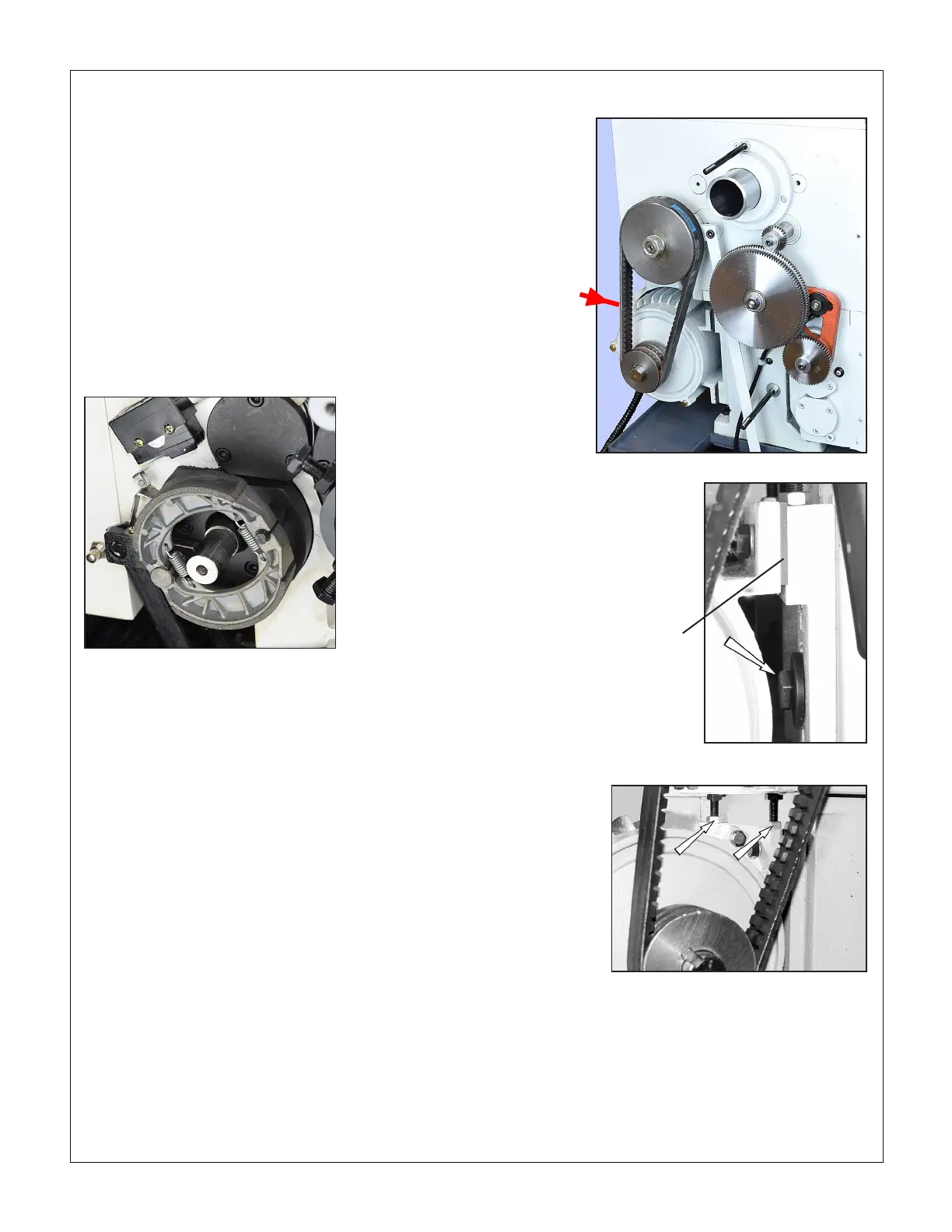

DRIVE BELT ADJUSTMENT

Figure 4-17 Test for belt tension

Figure 4-18 Motor frame bolts

Figure 4-19 Motor frame pusher screws

Vibration

damper

Loosen the two hex-head bolts securing the motor frame to the

headstock, Figure 4-18. Loosen the lock nuts on the pusher

screws, Figure 4-19, then adjust the screws to achieve the de-

sired belt tension. Re-tighten the lock nuts.

Loading...

Loading...