9

Copyright © 2020 Quality Machine Tools, LLCPM-1440GT v9 2020-10

Section 3 USING THE LATHE

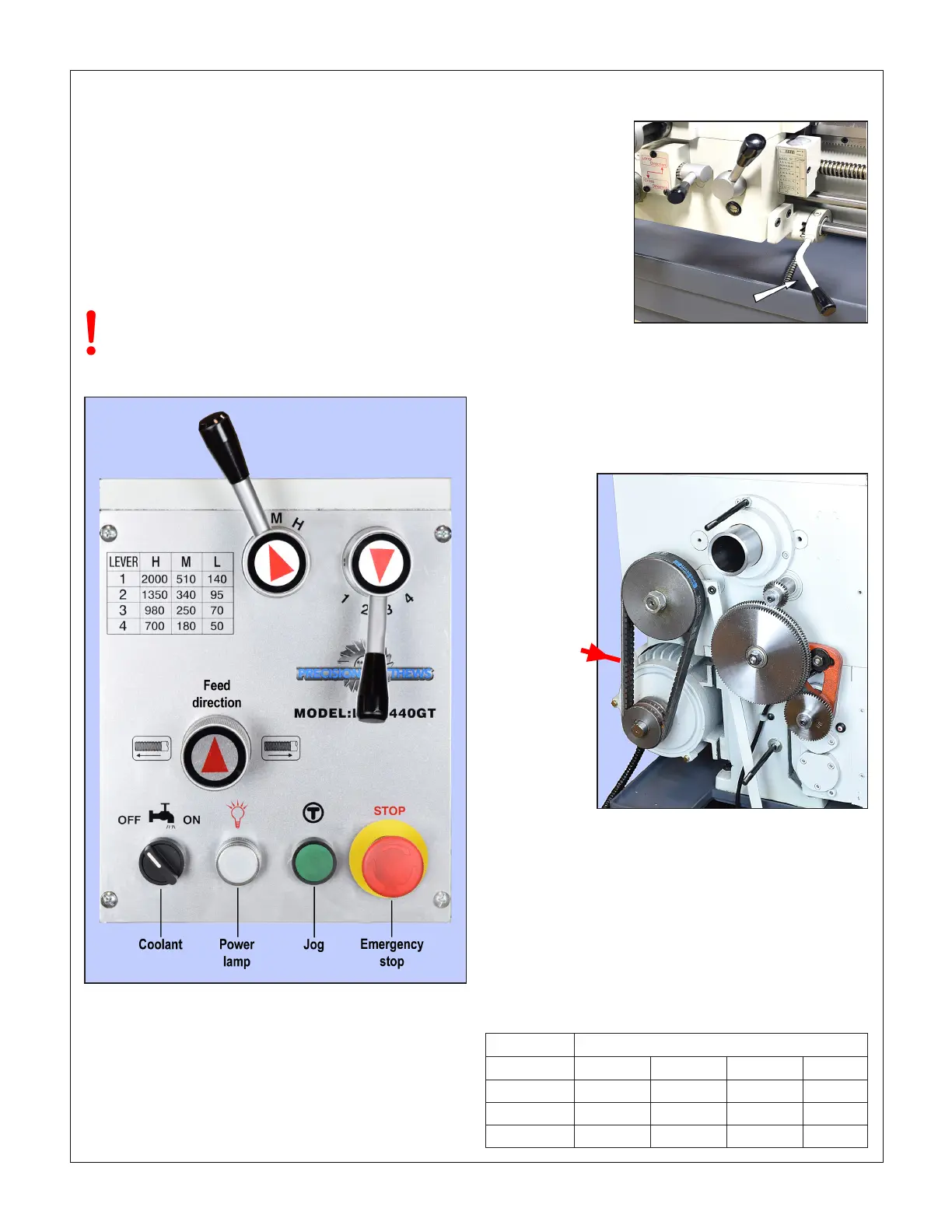

DRIVE TRAIN

Double-groove pulleys connect the motor to the gearbox, Fig-

ure 3-3. Belt tension will not usually require attention. If adjust-

ment is necessary, see Section 4.

What is not in this section ...

The PM-1440GT is a conventional engine lathe that requires

little explanation except for details specic to this particular

model — speed selection, thread cutting, and the saddle/

cross-slide power feed system. Because the user is assumed

to be familiar with general purpose metal lathes, this section

contains very little tutorial.

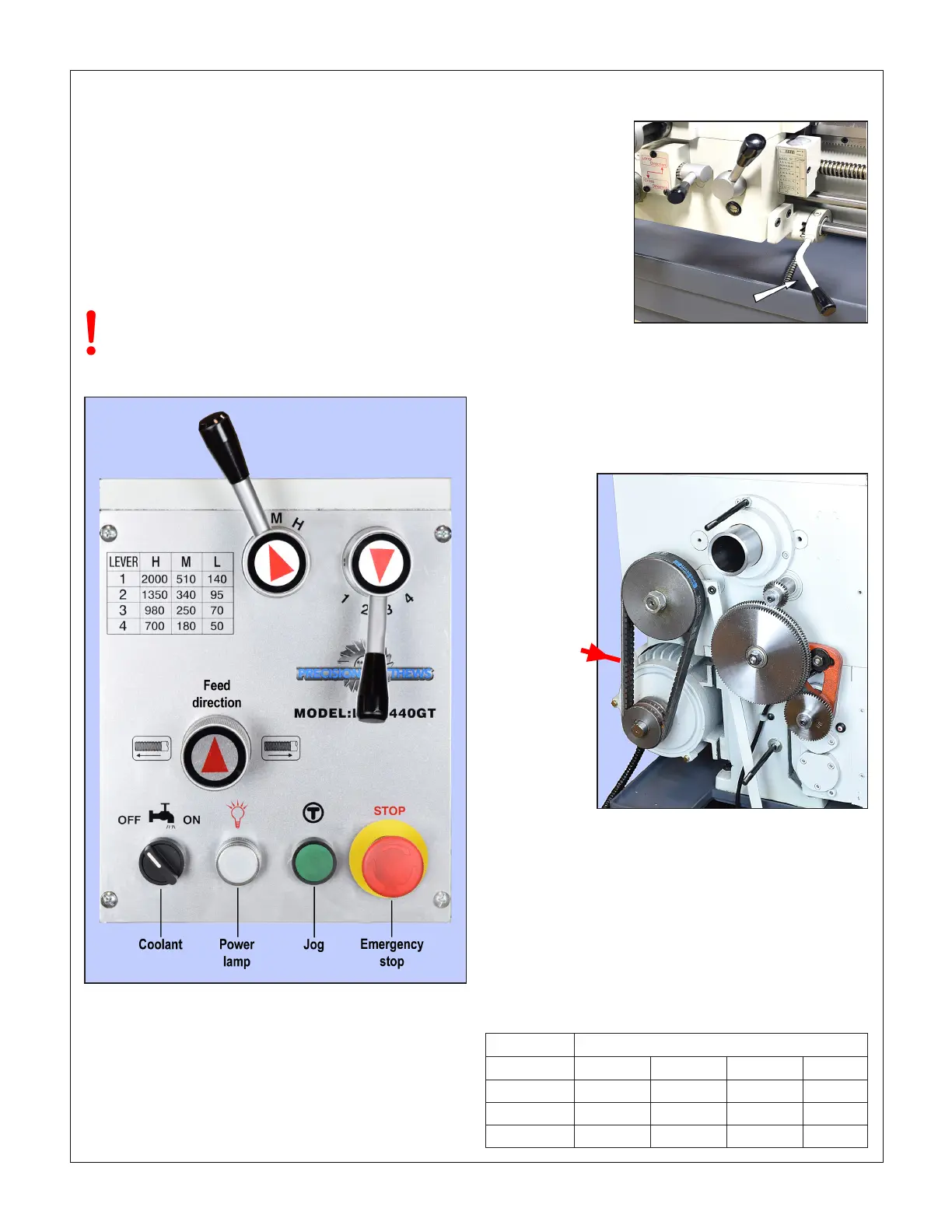

MOTOR CONTROLS Figure 3-1

Figure 3-1 Main control panel

Before doing ANYTHING, check the installation

instructions and power-up procedure in Section 1

STOP the motor before changing speed

Don't use JOG unless the gears are fully meshed

Figure 3-3 Vee belts & external change gears

Figure 3-2 Motor control lever

Mid-travel OFF, Down FORWARD, Up REVERSE

Before connecting power to the lathe, be sure the Motor Con-

trol Lever on the apron is set to OFF, Figure 3-2. Connect the

lathe to a 220 Vac outlet — the POWER lamp should light —

then operate the Motor Control Lever to run the spindle in the

desired direction.

Check that the E-Stop button and Footbrake interlocks func-

tion correctly.

Firm nger

pressure here

should deect

the Vee belt

about 1/4"

SPINDLE SPEEDS

The PM-1440GT has a twelve-speed headstock gearbox with

two shift levers, L-M-H & 1-2-3-4 (Speed Selection), Figure

3-1. Before changing speed, use the Motor Control, Figure

3-2, to STOP THE MOTOR, then move the shift levers to the

desired setting. This may need a little patience because it is

not always possible to go directly from one mesh to another.

Move the spindle back and forth by hand while trying to ease

the lever into its detent (meshed) position. Don’t use the JOG

button in this process — this may cause gear damage.

SPINDLE SPEED (RPM)

1 2 3 4

H RANGE 2000 1350 980 700

M RANGE 510 340 250 180

L RANGE 140 95 70 50

Loading...

Loading...