12

Copyright © 2020 Quality Machine Tools, LLCPM-1440GT v9 2020-10

TAILSTOCK

The tailstock leadscrew has a 10 TPI thread, with 4 inch travel.

Inch and metric graduated collars on the tailstock handwheel

read 0.001” and 0.02 mm per division. A transverse slot at the

narrow end of the internal taper (MT3) provides clearance for

drills and other devices with tang ends. To remove tooling from

the tailstock taper turn the handwheel counter-clockwise (han-

dle end view) until resistance is felt, then turn the handle a little

more to eject the tool. Conversely, to install a taper tool make

certain that the quill is out far enough to allow rm seating.

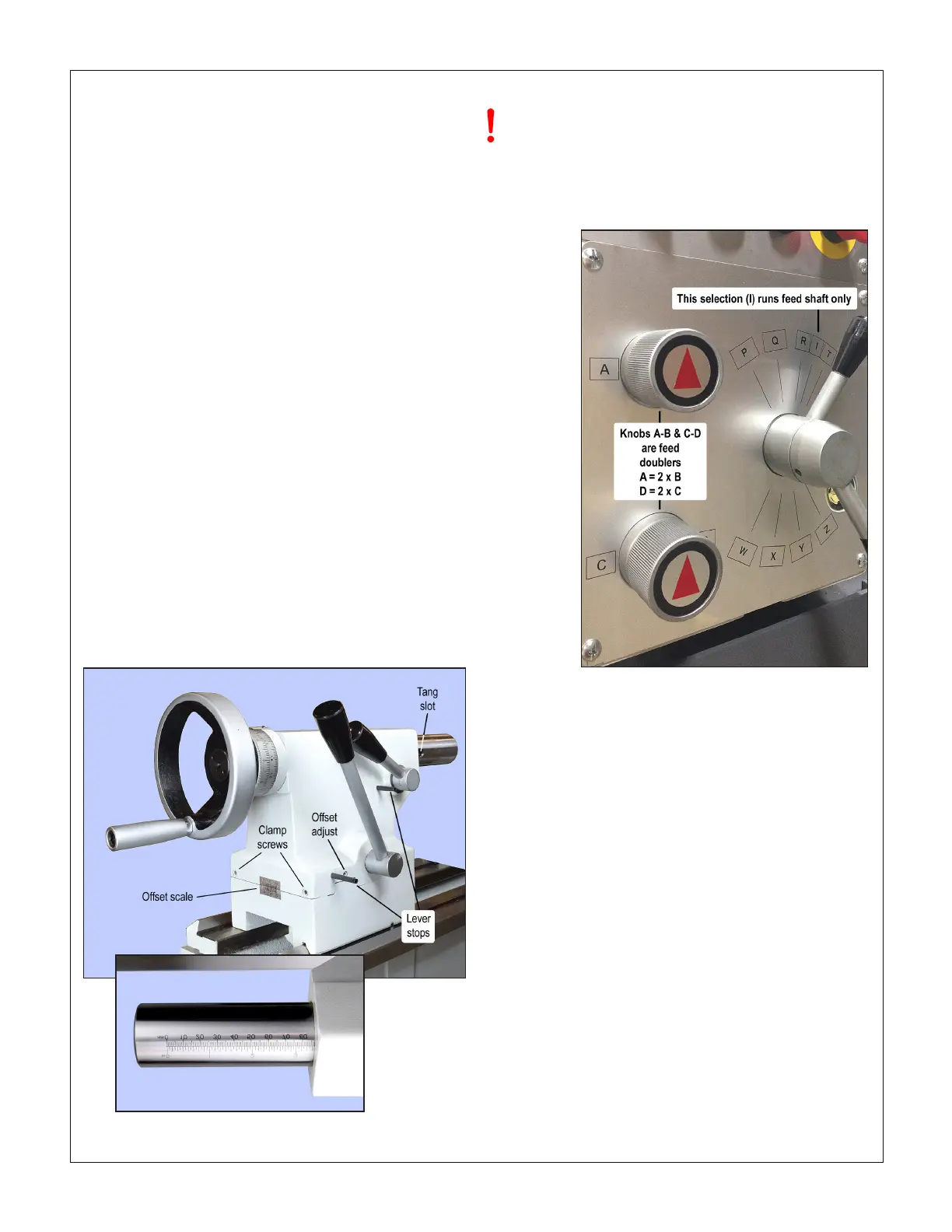

For taper turning the tailstock may be oset by adjusting set

screws on either side, Figure 3-10. To move the tailstock to

the front, for instance, the screw on the lever side would be

unscrewed, then the opposing set screw would be screwed in

to move the upper assembly. Clamp screws hold the tailstock

rmly against a transverse rib in the base casting. Loosen

them if necessary to allow osetting.

A visual indication of the oset is provided by a scale on the

back surface, but this is not a reliable measure for precise

work. In practice, the only way to determine the oset precisely

is to "cut and try' on the workpiece, or scrap stock, homing in

on the correct degree of oset in small increments.

The same issues arise when re-establishing "true zero" of the

tailstock, in other words returning it to the normal axis for rou-

tine operations. One way to avoid cut-and-try is to prepare in

advance a bar of (say) 1" diameter quality ground stock, with

precise center drillings at both ends (do this by indicating for

zero TIR in a 4-jaw chuck, not in a 3-jaw unless known to be

predictably accurate). The prepared bar can then be installed

between centers and indicated along its length.

Figure 3-10 Tailstock

SADDLE FEED GEARBOX

Stop the motor before changing feed direction or rate

The saddle feed can be to the left, right, or disengaged, as

selected by the Saddle Feed knob on the main control panel,

Figure 3-1.

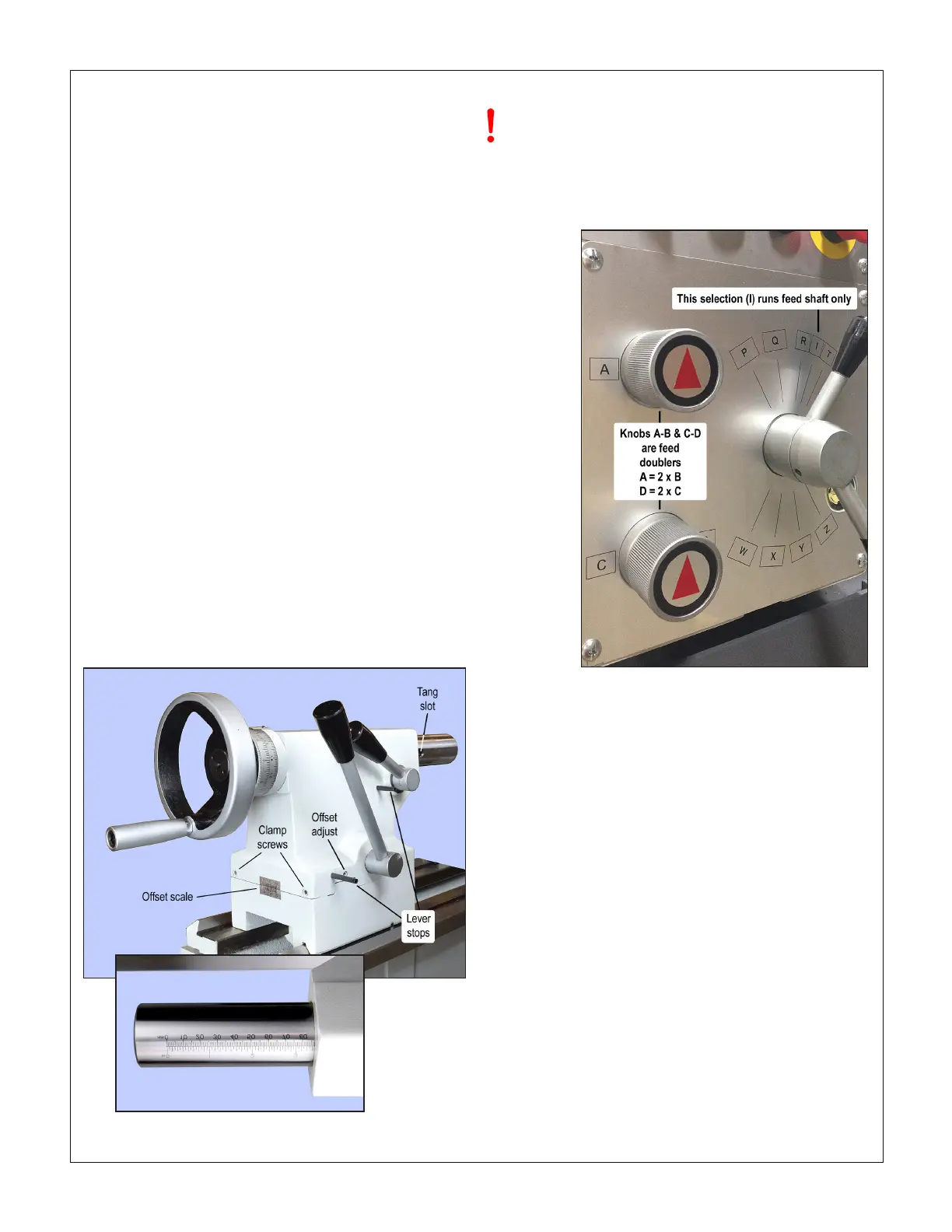

Figure 3-11 Saddle feed gearbox controls

ENGAGING THE POWER FEED

To activate the feed shaft set the upper lever on the gearbox,

Figure 3-11, to LETTER 'I' (selections P-Q-R-T are used only

for thread cutting).

The power feed lever on the apron, Figure 3-12, is active only

when the feed shaft is rotating (the split-nut lever engages

the leadscrew, and is typically used only for thread cutting).

When engaging power feed, move the lever gently, feeling

for the gears to mesh as you go. If the gears don’t engage at

the rst try, use the appropriate handwheel to jog the saddle

or cross-slide, whichever one you wish to move under power.

The split-nut lever — used for thread cutting — cannot be

engaged unless the power feed lever is NEUTRAL, neither

up or down.

The rate of power feed relative to spindle speed is set by the

lower lever on the gearbox, W-X-Y-Z, together with the "speed

doubler" knobs A-B and C-D. Feed rates are listed on the fol-

lowing page.

Loading...

Loading...