15

Copyright © 2020 Quality Machine Tools, LLCPM-1440GT v9 2020-10

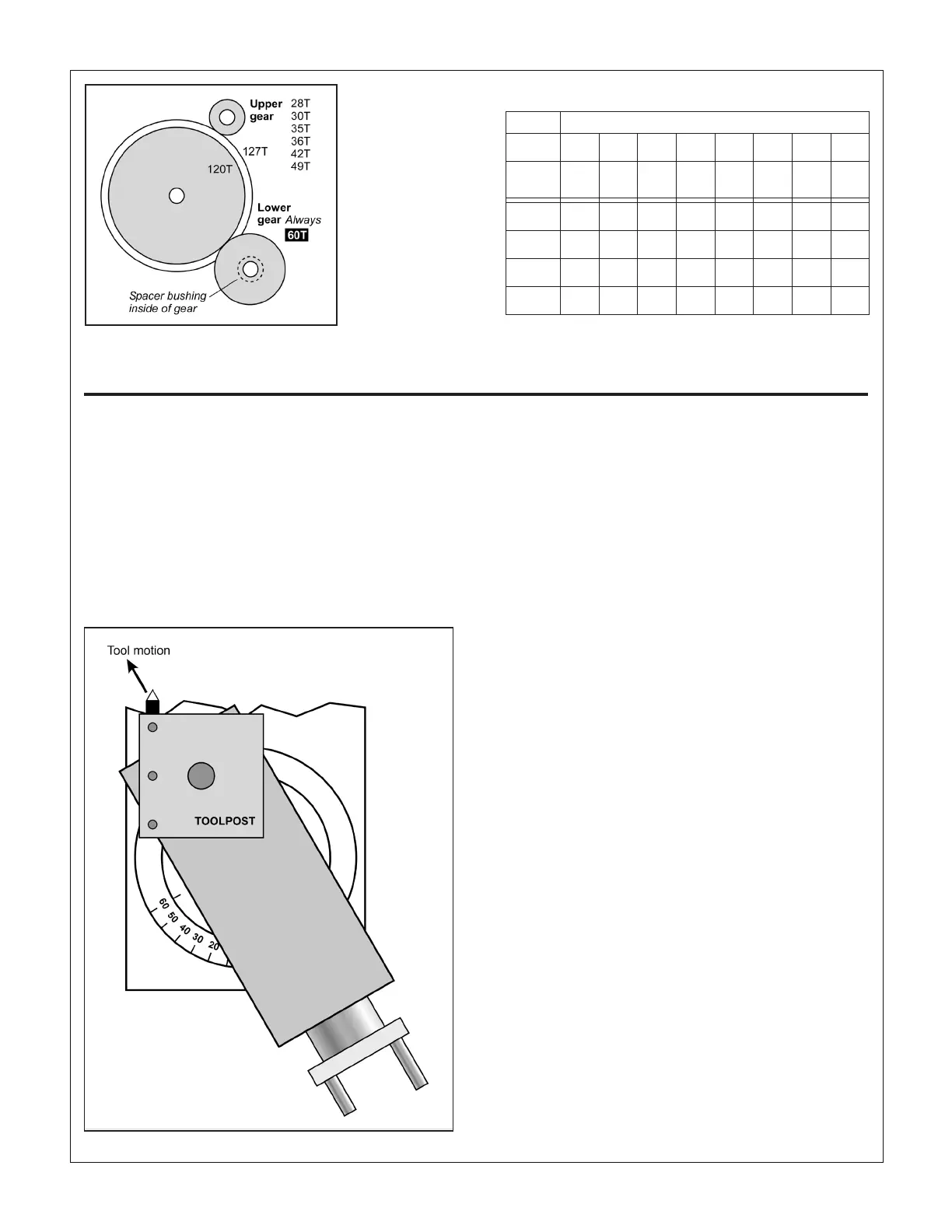

Figure 3-19

For all metric thread pitches lower gear is driven by the smaller (120T)

transposing gear.

Gear shifters

R-W Q-W R-W Q-W R-W Q-X Q-W Q-X

Upper

gear

28 28 42 35 49 30 49 36

A-D 3.2 4.0 4.8 5.0 5.6 6.0 7.0 7.2

B-D 1.6 2.0 2.4 2.5 2.8 3.0 3.5 3.6

A-C 0.8 1.0 1.2 1.25 1.4 1.5 1.75 1.8

B-C 0.4 0.5 9.6 0.7 0.75 0.9

Figure 3-20 Metric thread pitches (mm)

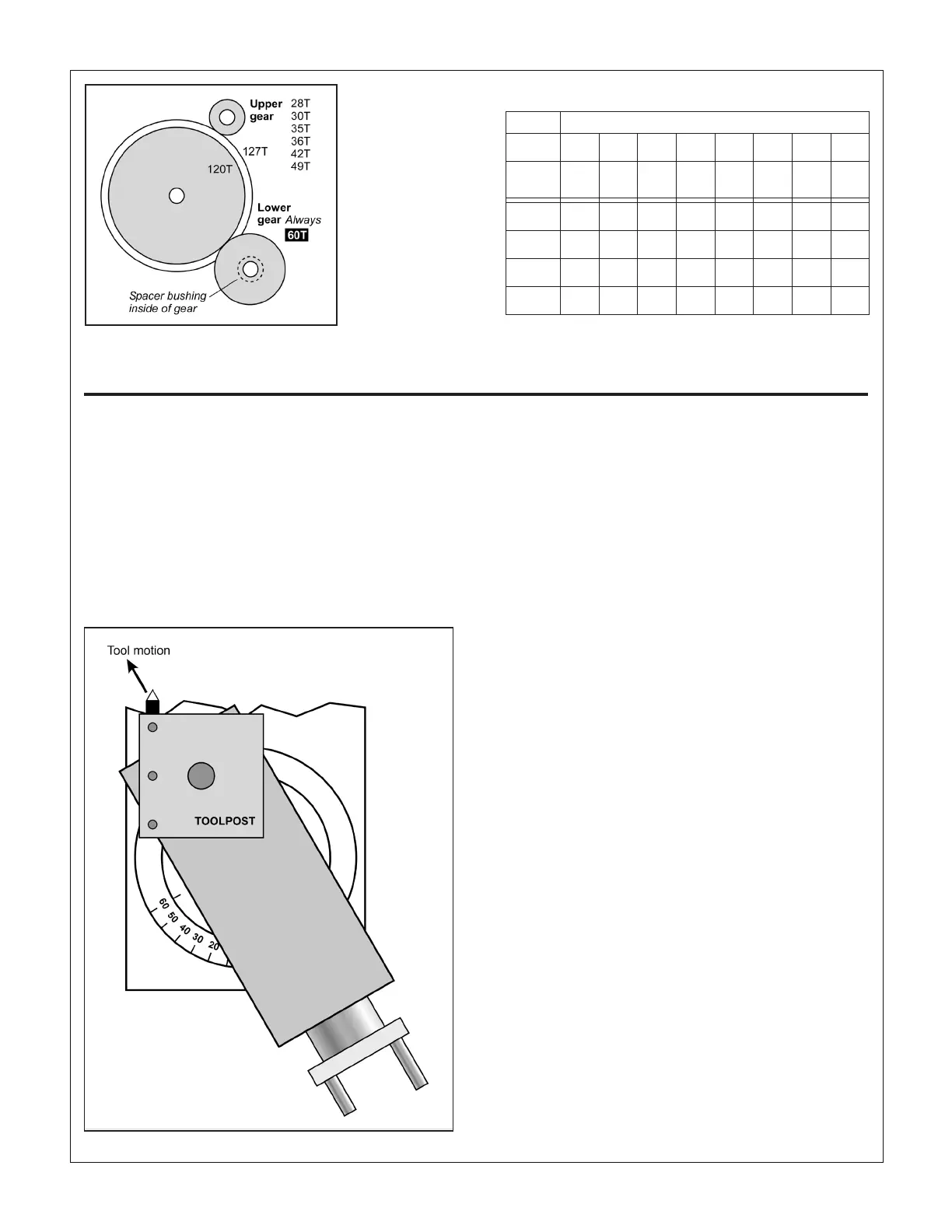

COMPOUND SETUP FOR THREAD CUTTING

Thread cutting on the lathe is unlike most other turning oper-

ations, for two reasons: 1. The cutting tool must be precisely

ground with an included angle of 60 degrees for most Amer-

ican and metric threads, and; 2. It is preferable to feed the

tool into the workpiece at an angle so it cuts mostly on the left

ank of the thread, Figure 3-21. The correct angle relative to

the cross-slide (zero degrees) is debatable — should it be 29,

29-1/2 or 30 degrees? Many machinists prefer 29 degrees be-

cause it holds the cutting tool marginally clear of the right ank

of the thread, close enough for cleanup of the ank while at the

same time avoiding appreciable rubbing.

Figure 3-21 Setting up the compound for 30

o

infeed

CUTTING PROCEDURE FOR TPI THREADS

This procedure assumes that a single point thread cutting tool

will be used, and that the threading dial assembly, Figure 3-22,

has been pivoted forward to engage its worm wheel with the

leadscrew.

The threading dial cannot used for metric threads! The

split-nut on the apron must be left engaged throughout

the entire process.

For metric and UNC/UNF threads the tool is ground to 60

o

(in-

cluded angle). It is installed so that its anks are exactly 30

o

either side of the cross axis, ideally with the compound o-

set as Figure 3-21. Single-point threads are cut in 10 or more

successive passes, each shaving a little more material o the

workpiece.

To make the rst thread-cutting pass the leadscrew is run at

the selected setting (tables on this, and preceding pages), and

the carriage is moved by hand to set the cutting tool at the

starting point of the thread. With the tool just grazing the work-

piece, the split-nut lever is lowered to engage the leadscrew.

This can be done at any point, provided the split-nut remains

engaged throughout the entire multi-pass thread cutting

process.

When the rst pass is completed, the tool is backed out clear

the workpiece (using the cross-slide), and the spindle is re-

versed to bring the saddle back to the starting point. The cross-

slide is returned to its former setting, then the tool is advanced

a few thousandths by the compound for the next pass. Each

successive pass is done in the same way, each with a slightly

increased infeed setting of the compound.

Many users working on U.S. threads save time by disengag-

ing the split-nut at the end of each cutting pass, reversing the

saddle by hand, then re-engaging, usually by reference to the

threading dial.

If the TPI number is divisible by 2 re-engagement can be done

at any line on the threading dial.

For all other TPI numbers every engagement, including the

rst, must at the point where a specic line on the threading

Loading...

Loading...