18

LAYOUTOPERATION

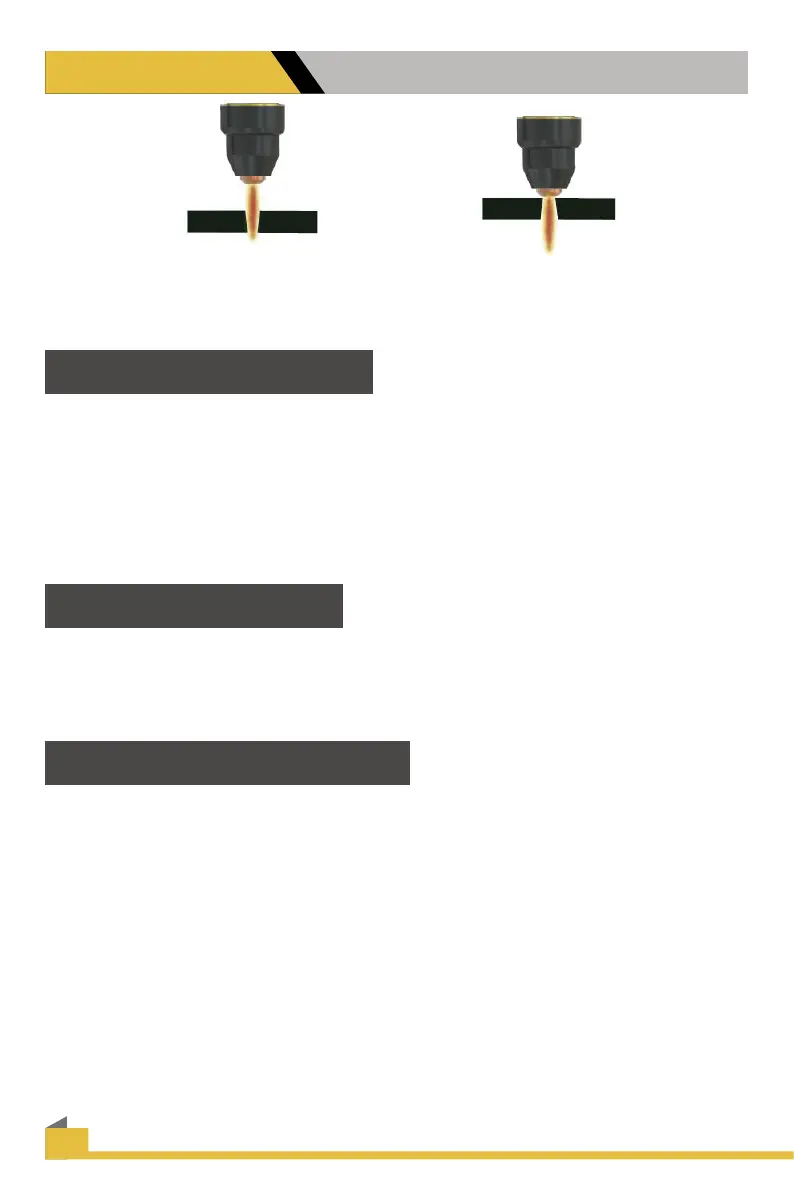

Torch height too high

excessive bevel, plasma

Stream may not cut all the

way through the material

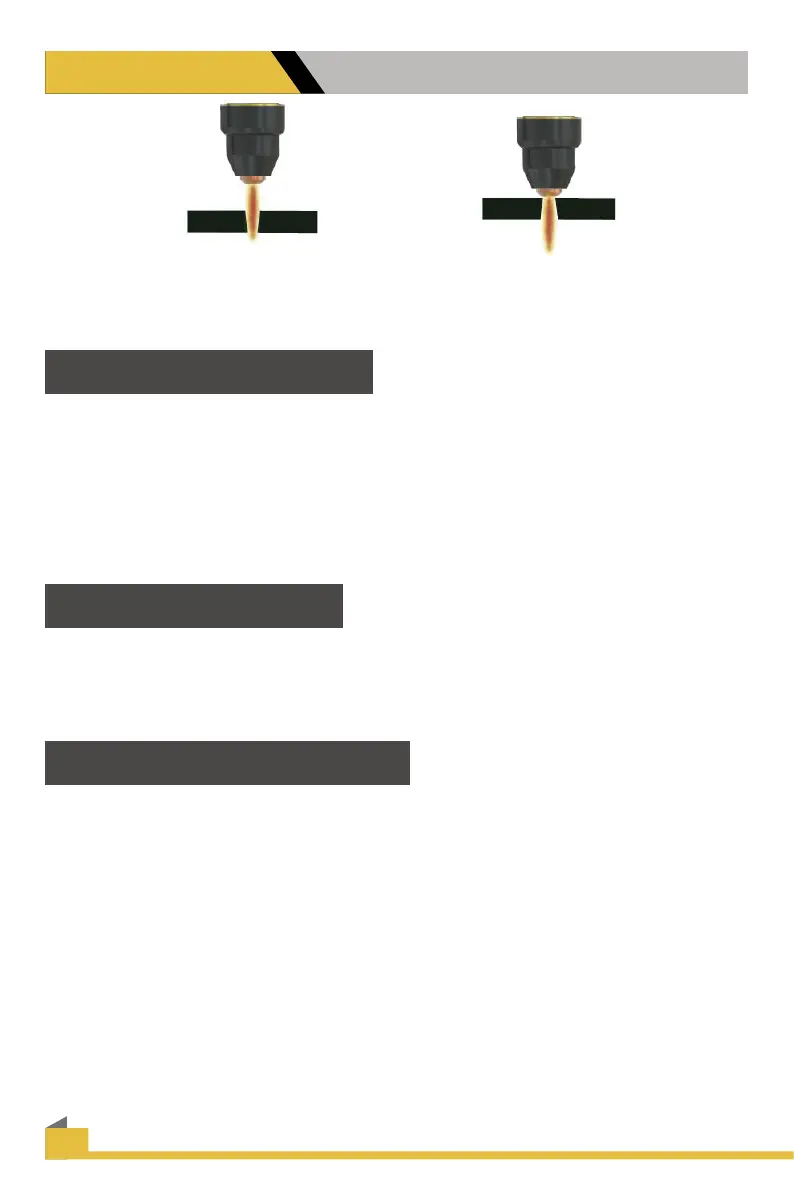

Torch height too low

Reverse bevel. Tip may

contact the work piece and

short out or damage the tip.

Tip size and condition

The tip orices focus the plasma stream to the work piece. It is important to use the correct size tip

for the amperage being used,for example a tip with a 3/64" orice is good for 0-40 amps whereas a

1/16" orice is better for 40-80 amps.

The low-amp tip has a smaller orice which maintains a narrow plasma stream at lower settings for

use on thin-gauge material. Using a 25 amp tip at an 60 amp setting will blow out and distort the tip

orice and require replacement. Conversely, using an 80-amp tip on the lower settings will not allow

you to focus the plasma stream as well and creates a wide kerf.The condi tion of the tip orice is

critical to the quality of the cut result, a worn or damaged tip orice will produce a distorted plasma

stream resulting in a poor cut quality.

Electrode condition

A xed gap is established between the electrode and the inside of the cutting tip.

Electrons arc across the gap, ionizing and super heating the air creating the plasma stream. The

electrode contains an insert in the end made of a highly conductive material called hafnium. This

insert erodes with use and develops a pit in the end of the electrode, when the pit becomes too

much poor quality cuts will result and necessitate replacement of the electrode.

Air pressure and volume

Air pressure, ow rate and air quality are critical to quality plasma cutting and consumable life span.

The required air pressure and volume can vary from model to model and the manufacturer will

provide the specs.The air pressure is pre-set at 4.5 psi and requires a ow rate of 6.0 CF/M. The

volume capacity of your compressor is important, if you have a small compressor with exactly the

same l/min rating as the plasma, then the compressor will run continuously when you are plasma

cutting, a compressor with a l/min rating slightly higher than the plasma would be more adequate.

If you are doing a lot of cutting, cutting thick plate (same air consumption but slower cut speeds =

longer cut time) then choose a compressor at 1.5 to 2 times the plasma system requirement.

Loading...

Loading...