45

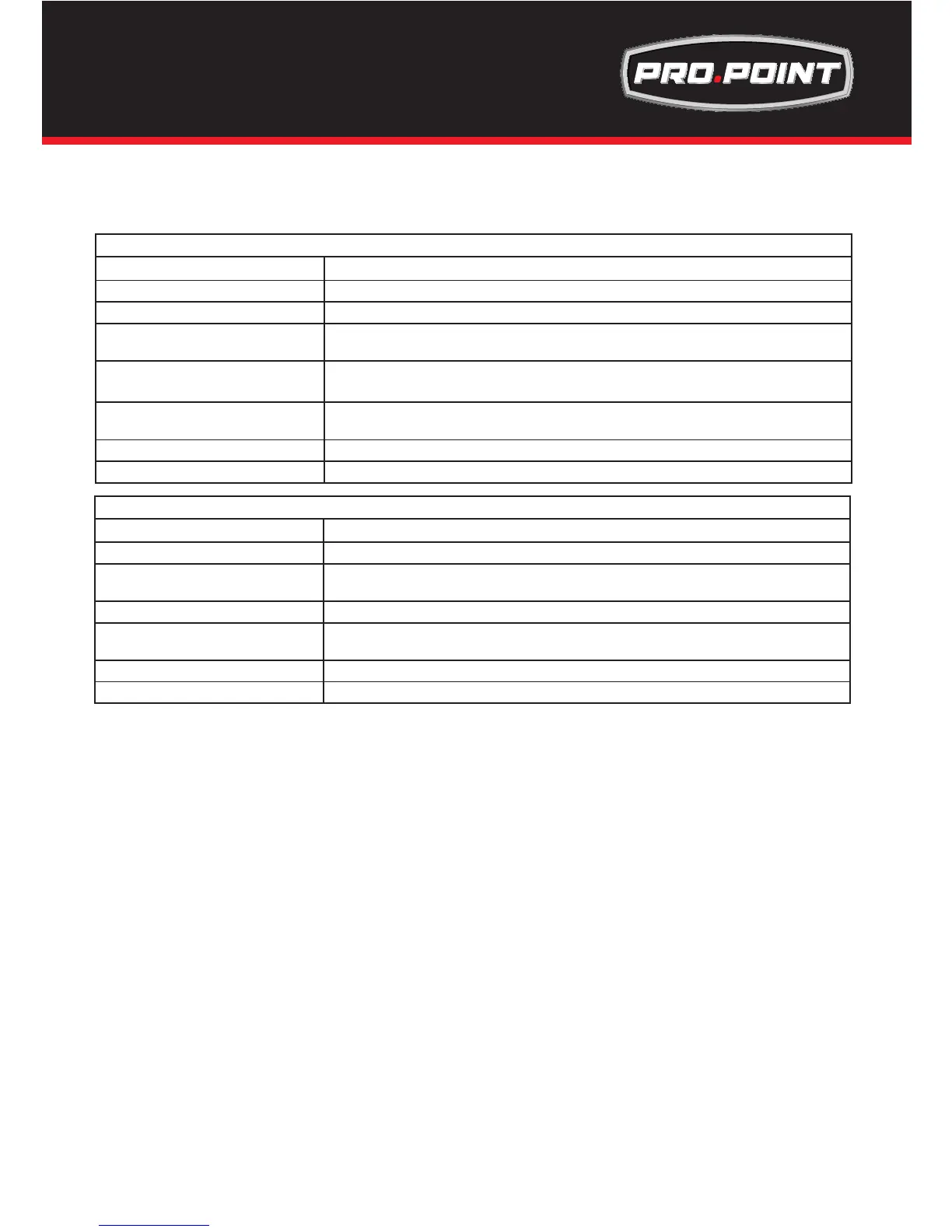

7: Arc wanders during DC welding

Possible Reason Suggested Remedy

Poor gas ow Check and set the gas ow between 21-30cfh ow rate

Incorrect arc length Lower torch so that the tungsten is off of the work piece 1/8-1/4in

Tungsten incorrect or in poor condi-

tion

Check that correct type of tungsten is being used. Remove 1/2in from the weld end of

the tungsten and re sharpen the tungsten

Poorly prepared tungsten Grind marks should run lengthwise with tungsten, not circular. Use proper grinding

method and wheel.

Contaminated base metal Remove contaminating materials like paint, grease, oil, and dirt, including mill scale from

base metal.

Contaminated ller wire Remove all grease, oil, or moisture from ller metal.

Incorrect ller wire Check the ller wire and change if necessary

At initial set up and at regular intervals we recommend to check for gas leakage.

Recommended procedure is as follows:

1. Connect the regulator and gas hose assembly and tighten all connectors and clamps.

2. Slowly open the cylinder valve.

3. Set the ow rate on the regulator to approximately 21-30cfh.

4. Close the cylinder valve and pay attention to the needle indicator of the contents pressure

gauge on the regulator, if the needle drops away towards zero there is a gas leak.

Sometimes a gas leak can be slow and to identify it will require leaving the gas pressure in the

regulator and line for an extended time period. In this situation it is recommended to open the

cylinder valve, set the ow rate to 21-30cfh, close the cylinder valve and check after a

minimum of 15 minutes.

5. If there is a gas loss then check all connectors and clamps for leakage by brushing or spraying

with soapy water, bubbles will appear at the leakage point.

6. Tighten clamps or ttings to eliminate gas leakage.

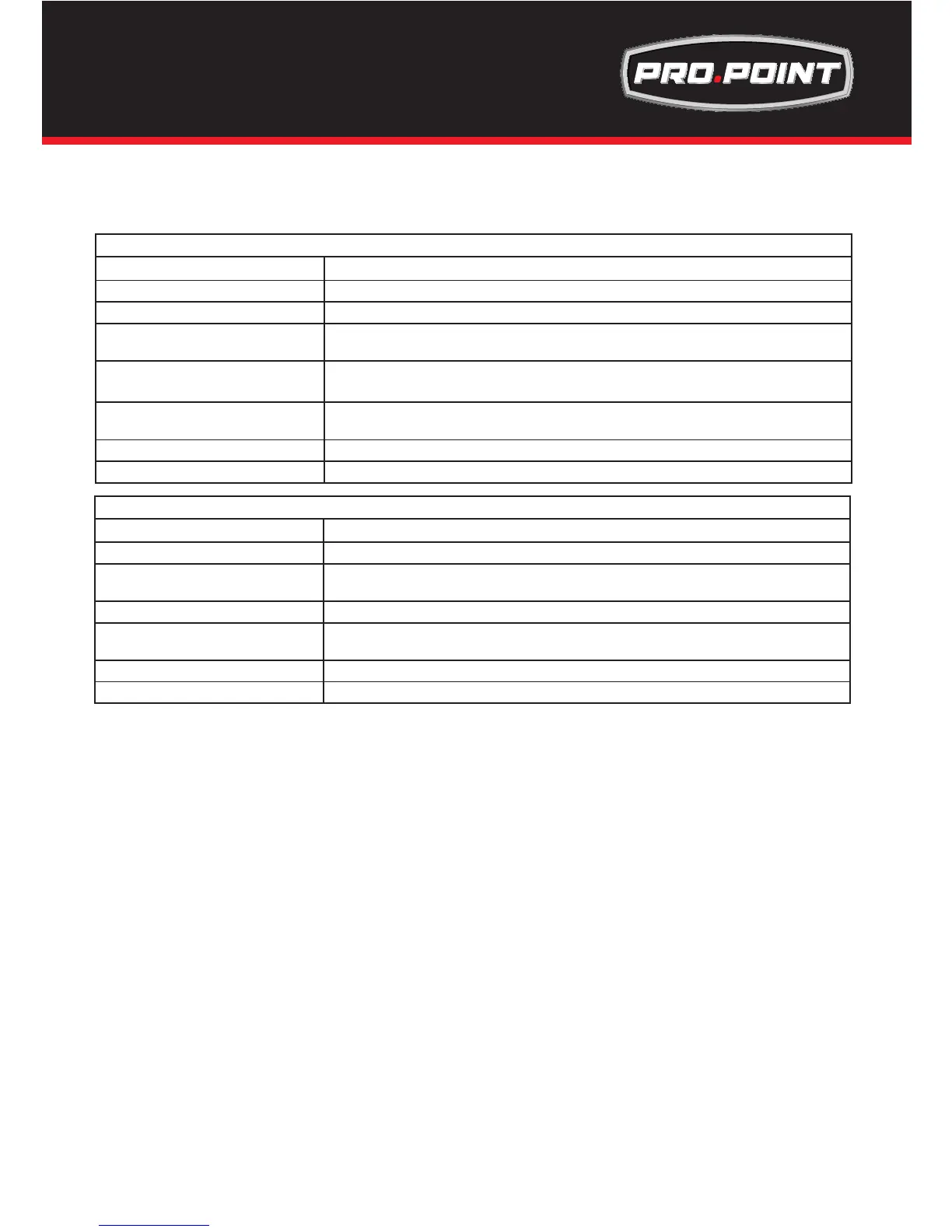

8: Arc difcult to start or will not start DC welding

Possible Reason Suggested Remedy

Incorrect machine set up Check machine set up is correct

No gas, incorrect gas ow Check the gas is connected and cylinder valve open, check hoses, gas valve and torch

are not restricted. Set the gas ow between 10 - 15 l/min ow rate

Tungsten is contaminated Remove 10mm of contaminated tungsten and re grind the tungsten

Incorrect tungsten size and or tung-

sten being used

Check and change the size and or the tungsten if required

Loose connection Check all connectors and tighten

Earth clamp not connected to work Connect the earth clamp directly to the work piece wherever possible

TIG WELDING TROUBLE SHOOTING - Continued

Loading...

Loading...