•

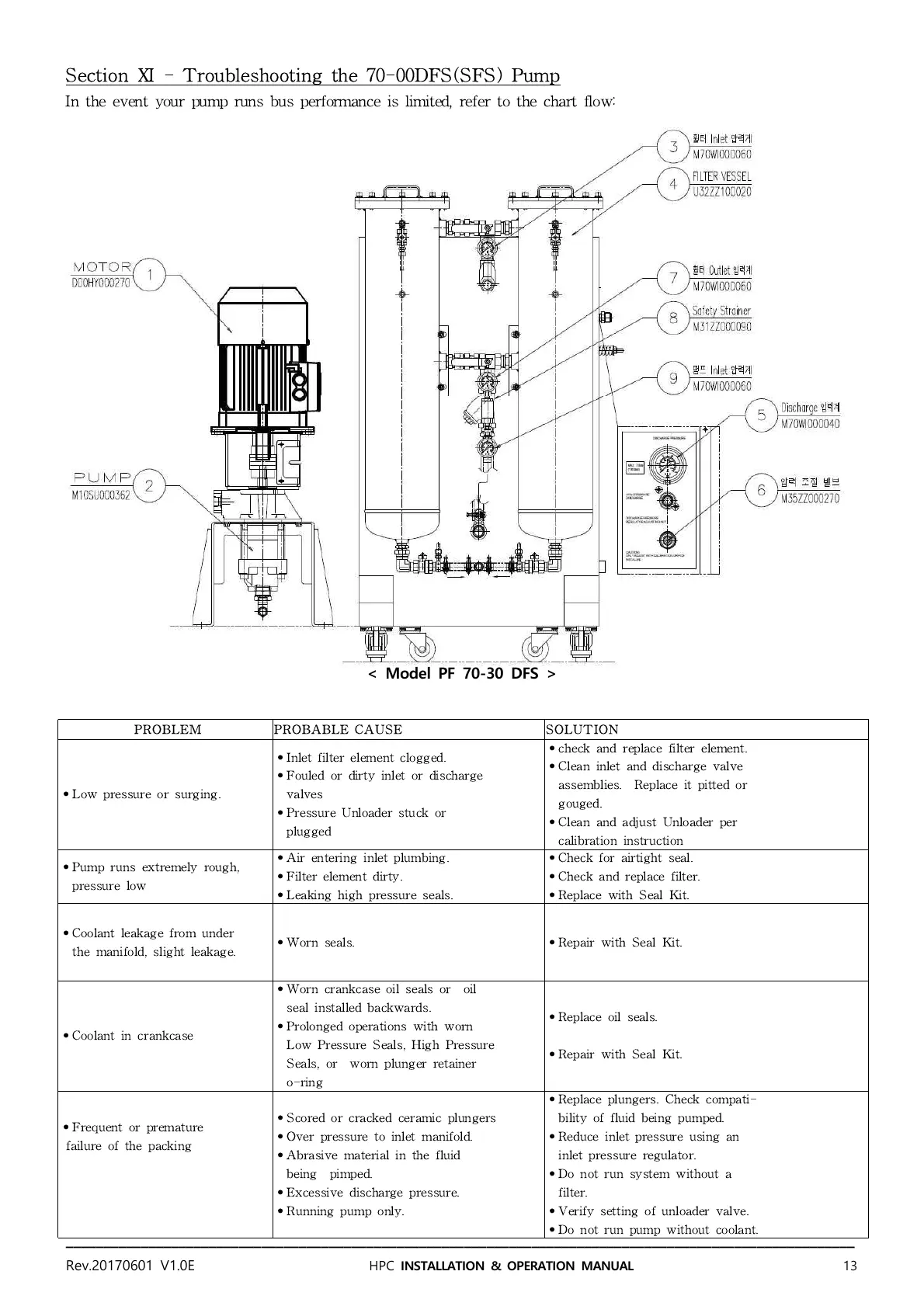

Low pressure or surging.

•

Inlet filter element clogged.

•

Fouled or dirty inlet or discharge

valves

•

Pressure Unloader stuck or

plugged

•

check and replace filter element.

•

Clean inlet and discharge valve

assemblies. Replace it pitted or

gouged.

•

Clean and adjust Unloader per

calibration instruction

•

Pump runs extremely rough,

pressure low

•

Air entering inlet plumbing.

•

Filter element dirty.

•

Leaking high pressure seals.

•

Check for airtight seal.

•

Check and replace filter.

•

Replace with Seal Kit.

•

Coolant leakage from under

the manifold, slight leakage.

•

Worn crankcase oil seals or oil

seal installed backwards.

•

Prolonged operations with worn

Low Pressure Seals, High Pressure

Seals, or worn plunger retainer

o-ring

•

Replace oil seals.

•

Repair with Seal Kit.

•

Frequent or premature

failure of the packing

•

Scored or cracked ceramic plungers

•

Over pressure to inlet manifold.

•

Abrasive material in the fluid

being pimped.

•

Excessive discharge pressure.

•

Running pump only.

•

Replace plungers. Check compati-

bility of fluid being pumped.

•

Reduce inlet pressure using an

inlet pressure regulator.

•

Do not run system without a

filter.

•

Verify setting of unloader valve.

•

Do not run pump without coolant.

Rev.20170601 V1.0E HPC INSTALLATION & OPERATION MANUAL 13

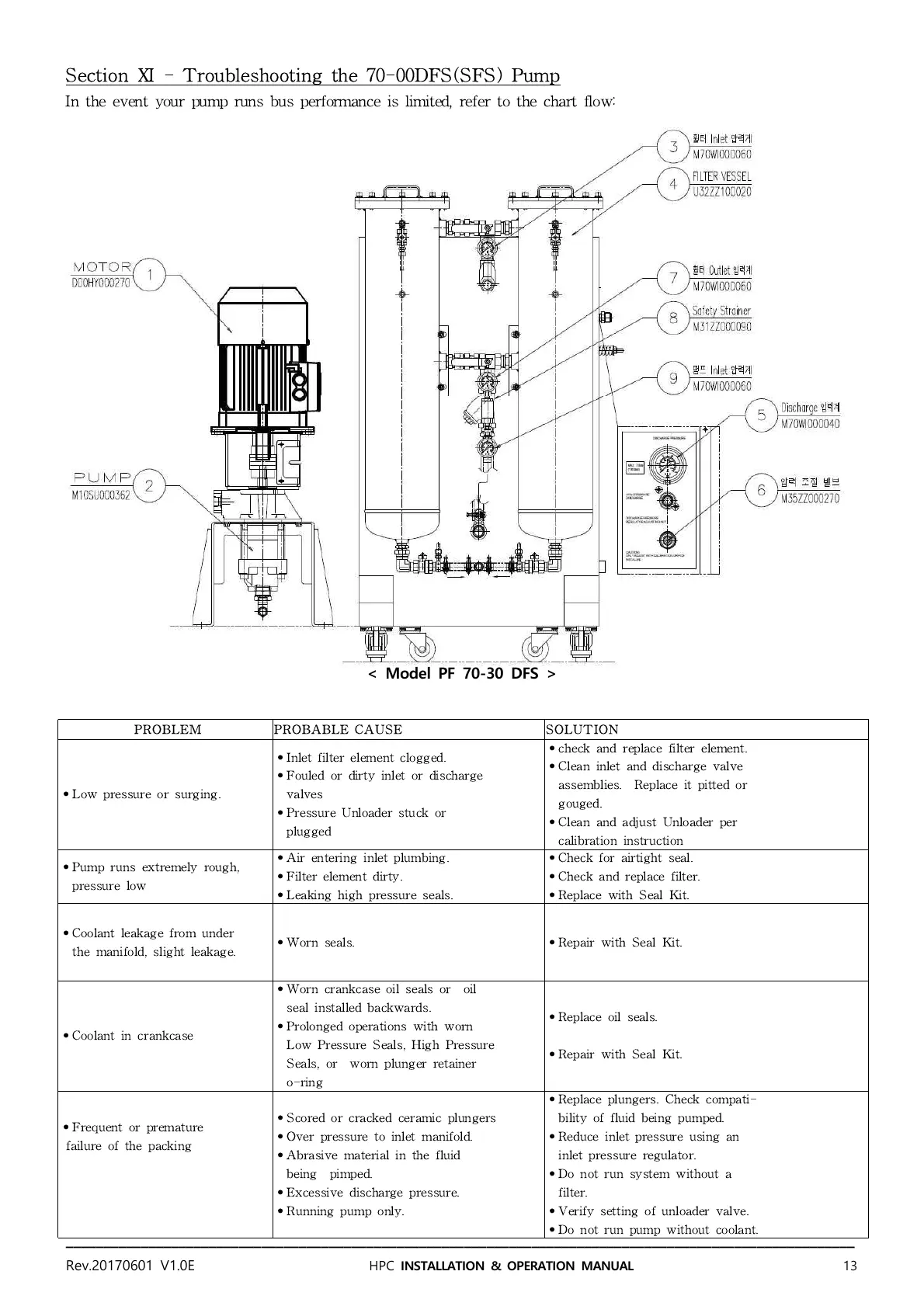

Section Ⅺ - Troubleshooting the 70-00DFS(SFS) Pump

In the event your pump runs bus performance is limited, refer to the chart flow:

< Model PF 70-30 DFS >

Loading...

Loading...