Rev.20170601 V1.0E HPC INSTALLATION & OPERATION MANUAL 9

Section Ⅵ - System Startup

START-UP PROCEDURE

1. Verify coolant level in machine reservoir is at least 3/4 full.

2. Turn on power to both the supply pump and the HPC pump.

3. A fully primed system will run smoothly and deliver steady flow. Check the inlet pressure.

Inlet pressure 1.2Bar(14psi)~4.1Bar(60psi).

4. Listen for any erratic noise; look for unsteady flow.

5. If the system has an air lock in the high pressure lines, the pump may fail to prime. Follow the instructions

for Setting Pressure below to remove air that may be trapped in the pump manifold and high pressure lines.

Section Ⅶ - Setting Pressure / Pressure Regulating Valve

The Pressure Regulating Valve is the system safety valve to prevent over-pressurization.

Under no

circumstances

should the setting be higher than 70 Bar(1000 psi) for HPC Model 70-00DF(SF).

To Check the Regulator Set Point:

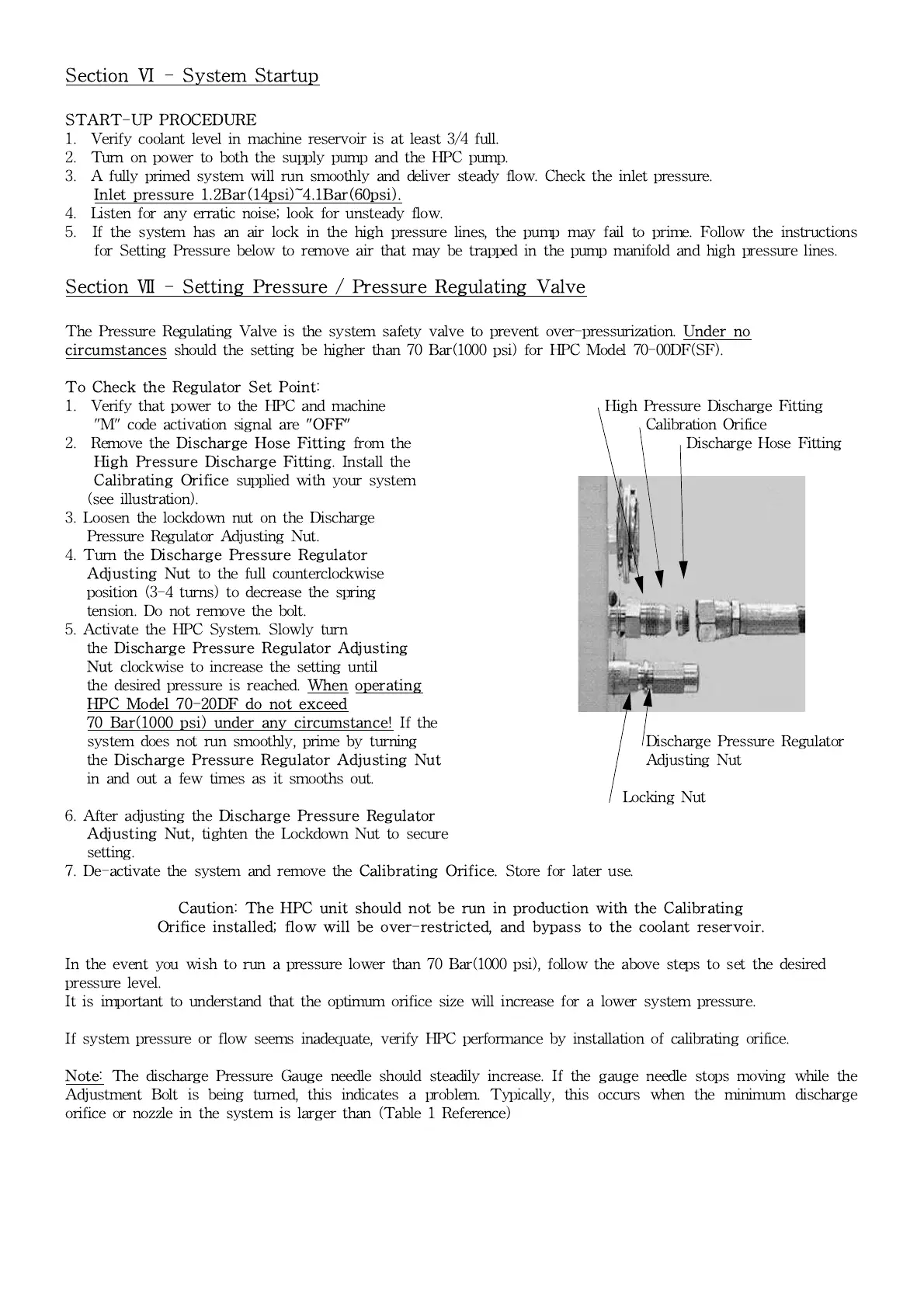

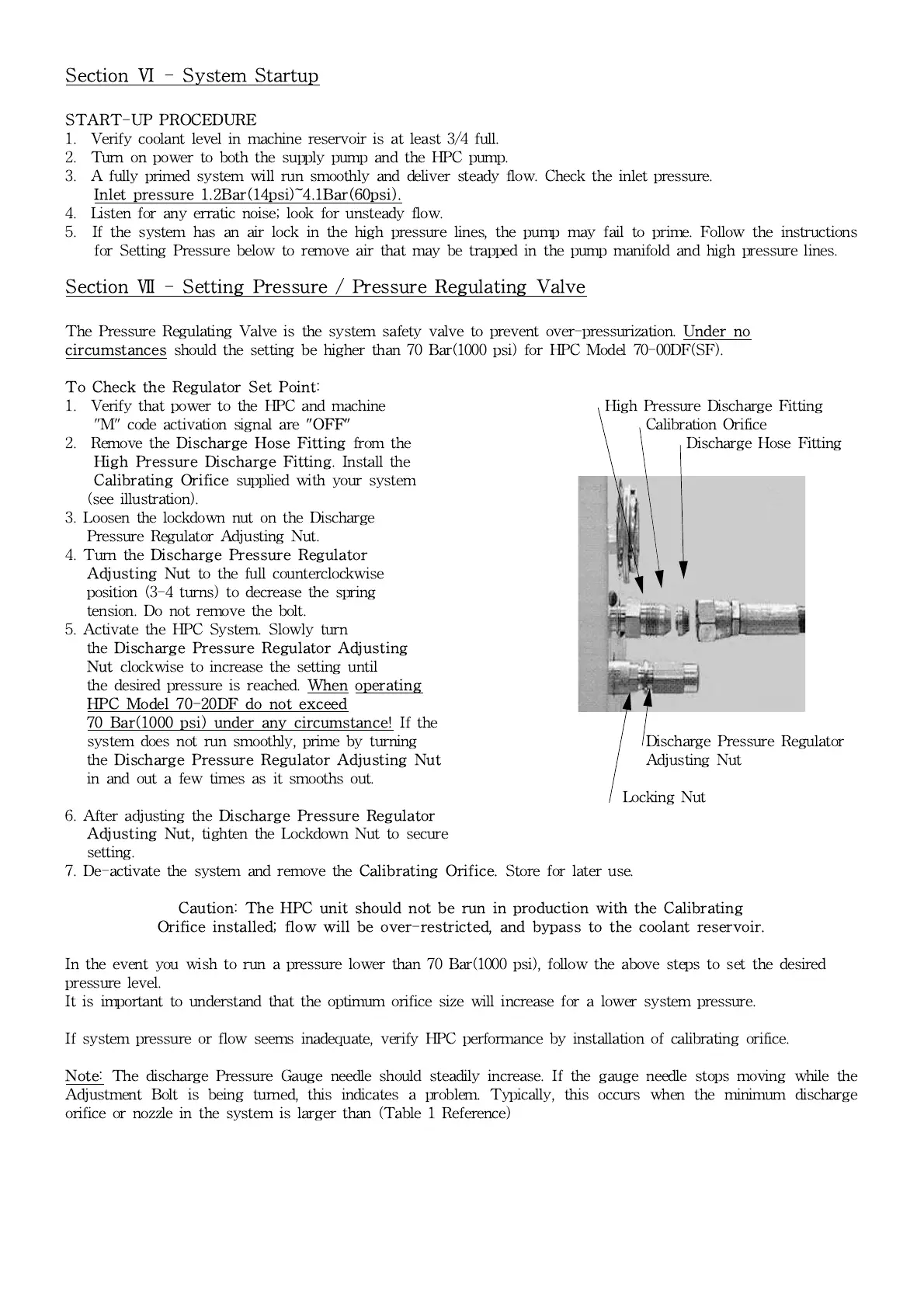

1. Verify that power to the HPC and machine High Pressure Discharge Fitting

"M" code activation signal are

"OFF"

Calibration Orifice

2. Remove the

Discharge Hose Fitting

from the Discharge Hose Fitting

High Pressure Discharge Fitting

. Install the

Calibrating Orifice

supplied with your system

(see illustration).

3. Loosen the lockdown nut on the Discharge

Pressure Regulator Adjusting Nut.

4. Turn the

Discharge Pressure Regulator

Adjusting Nut

to the full counterclockwise

position (3-4 turns) to decrease the spring

tension. Do not remove the bolt.

5. Activate the HPC System. Slowly turn

the

Discharge Pressure Regulator Adjusting

Nut

clockwise to increase the setting until

the desired pressure is reached.

When operating

HPC Model 70-20DF do not exceed

70 Bar(1000 psi) under any circumstance!

If the

system does not run smoothly, prime by turning Discharge Pressure Regulator

the

Dis

c

harge Pressure Regulator Adjusting Nut

Adjusting Nut

in and out a few times as it smooths out.

Locking Nut

6. After adjusting the

Discharge Pressure Regulator

Adjusting Nut,

tighten the Lockdown Nut to secure

setting.

7. De-activate the system and remove the

Calibrating Orifice.

Store for later use.

Caution: The HPC unit should not be run in production with the Calibrating

Orifice installed; flow will be over-restricted, and bypass to the coolant reservoir.

In the event you wish to run a pressure lower than 70 Bar(1000 psi), follow the above steps to set the desired

pressure level.

It is important to understand that the optimum orifice size will increase for a lower system pressure.

If system pressure or flow seems inadequate, verify HPC performance by installation of calibrating orifice.

Note:

The discharge Pressure Gauge needle should steadily increase. If the gauge needle stops moving while the

Adjustment Bolt is being turned, this indicates a problem. Typically, this occurs when the minimum discharge

orifice or nozzle in the system is larger than (Table 1 Reference)

Loading...

Loading...