Rev.20170601 V1.0E HPC INSTALLATION & OPERATION MANUAL 6

・

Do not use inlet hoses or components(valves, fittings, etc.)smaller than 15.9mm(5/8") I.D.

・

If elbows are required in the inlet plumbing, 45°fittings are preferred to 90°fittings. Try to arrange sweeping

hose curves if 90°routings are required.

・

Use thread sealant on any PT/NPT fittings in the HPC inlet plumbing. Any leaking joints can allow air to

be drawn into the system and cause cavitation. Sealant is not required for JIC 37°fittings.

・

If a shutoff valve is used in the inlet plumbing, it should be a full opening type and the opening through the

valve should be no smaller than 19mm(3/4") I.D.

Do not

run the HPC with the shutoff valve closed.

・

Do not connect rigid piping directly to the HPC coolant inlet. A flexible hose should be used to reduce

vibrations in the plumbing. Hose kits are available from HPC.

・

Install hose or piping supports where necessary to relieve strain and to minimize vibration.

Connect

Inlet Hose

and

Bypass/Drain Hose

. Use pipe sealant on the fitting threads. Route the

Bypass Hose

to

the coolant tank, as far as possible from the

Supply Pump

inlet (to reduce the change of turbulence and

cavitation). The

Bypass Hose

should be secured at the coolant tank end to prevent the hose from being ejected

from the tank.

CAUTION: Never install shutoff valves in the bypass/drain line.

HIGH PRESSURE HOSE GUIDELINES

Use at least 0.9M(3 ft.) of flexible hose between the HPC high pressure

Discharge Fitting

and any fixed

connection or rigid piping at the machine. This is a protective measure to reduce vibration in the machine's coolant

plumbing. A Pulsation Dampening Assembly is available to further minimize any adverse effects caused by high

pressure pulsations.

If the machine's coolant hoses are not rated for a minimum working pressure of 100 Bar(1500psi)prior to installing

a HPC Model 70-20, they should be replaced. Recommended discharge hose size is 12.7mm(1/2")I.D. Line size

should not be smaller than 9.5mm(3/8")I.D. Consult the factory for use of smaller discharge line sizes.

The

Discharge Fitting

on the HPC is a 3/4" (-12)37°, JIC male hydraulic fitting.

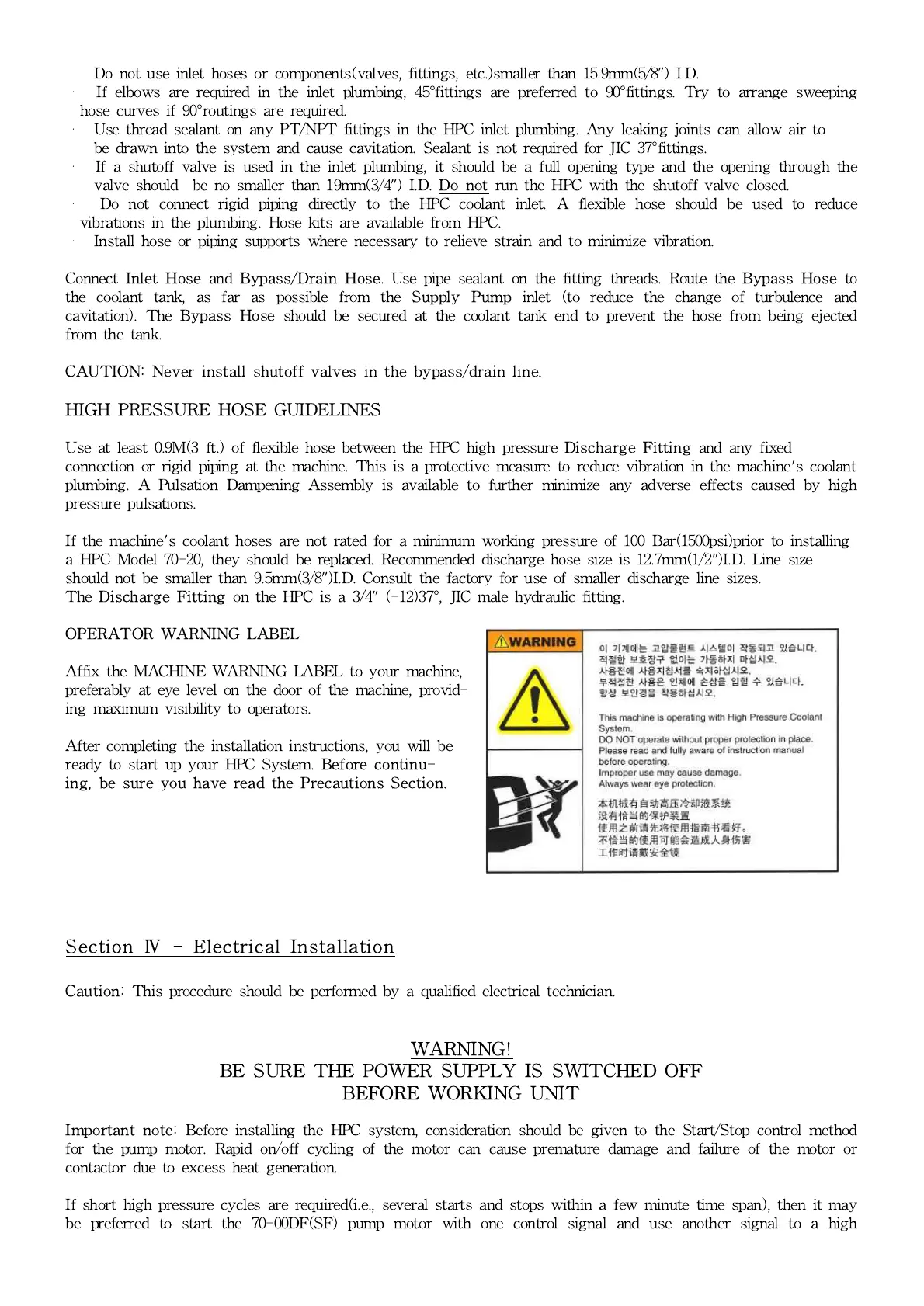

OPERATOR WARNING LABE

L

Affix the MACHINE WARNING LABEL to your machine,

preferably at eye level on the door of the machine, provid-

ing maximum visibility to operators.

After completing the installation instructions, you will be

ready to start up your HPC System.

Before continu-

ing, be sure you have read the Precautions Section.

Section Ⅳ - Electrical Installation

Caution:

This procedure should be performed by a qualified electrical technician.

WARNING!

BE SURE THE POWER SUPPLY IS SWITCHED OFF

BEFORE WORKING UNIT

Important note:

Before installing the HPC system, consideration should be given to the Start/Stop control method

for the pump motor. Rapid on/off cycling of the motor can cause premature damage and failure of the motor or

contactor due to excess heat generation.

If short high pressure cycles are required(i.e., several starts and stops within a few minute time span), then it may

be preferred to start the 70-00DF(SF) pump motor with one control signal and use another signal to a high

Loading...

Loading...