Rev.20170601 V1.0E HPC INSTALLATION & OPERATION MANUAL 8

PRIOR TO INITIAL START-UP, be sure that:

・

Coolant level in the machine reservoir is sufficient to supply the HPC.

・

Any shut-off valves in the inlet lines are open, and the high pressure lines are not blocked.

・

All fittings are tight.

・

The oil level in the HPC pump reservoir is within the acceptable range.

・

The Pressure Regulating Valve adjusting bolt on the outlet of the pump is backed out to the full counter-

clockwise position to relieve spring tension. This assures that the pump starts under minimum pressure.

・

Either a bag filter or pleated cartridge element has been installed, the o-rings and wire filter hold downs have

seated properly, and the filter lids have been tightened securely.

・

All air has been purged from both 70-00DF(SF) filter canister.

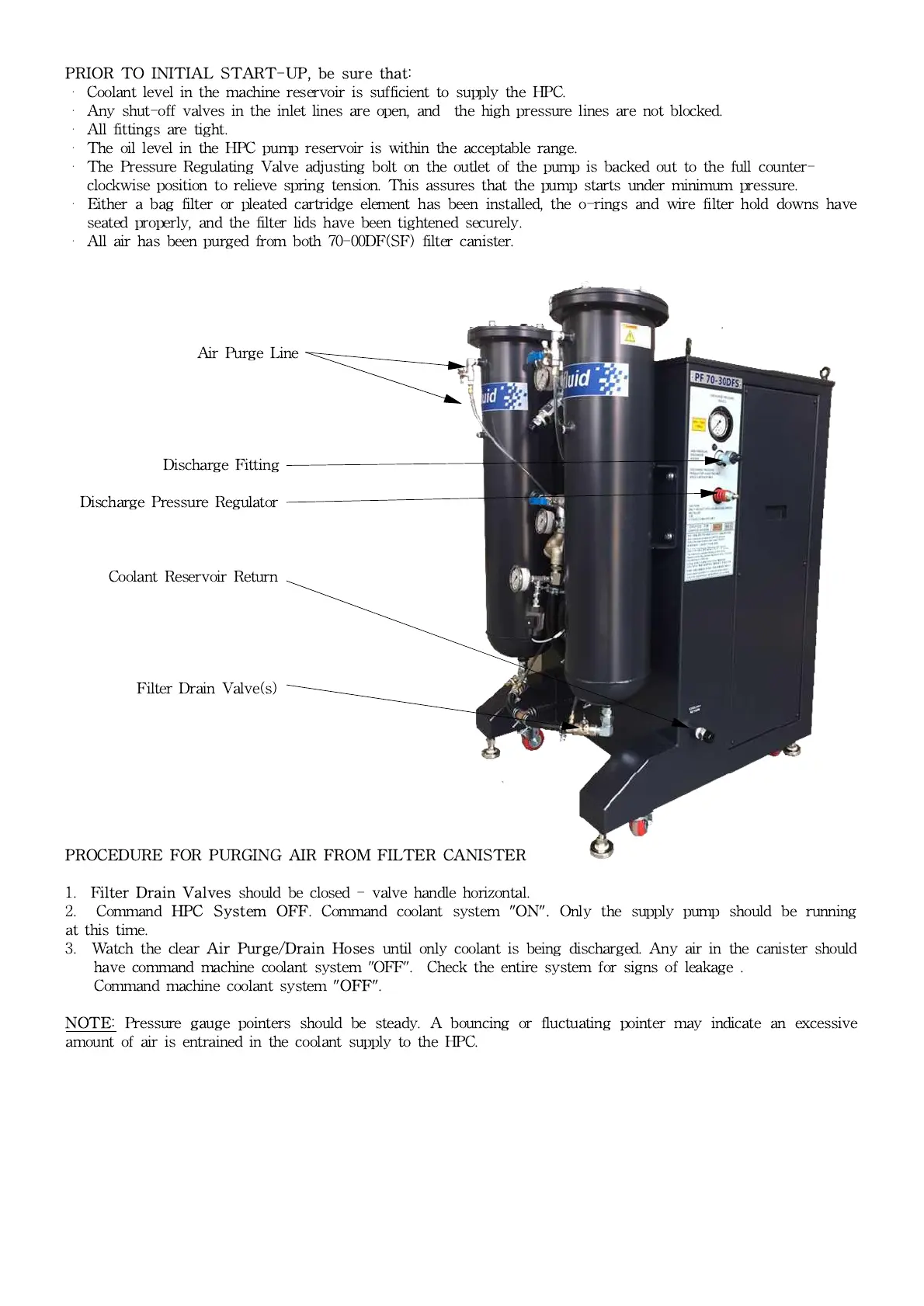

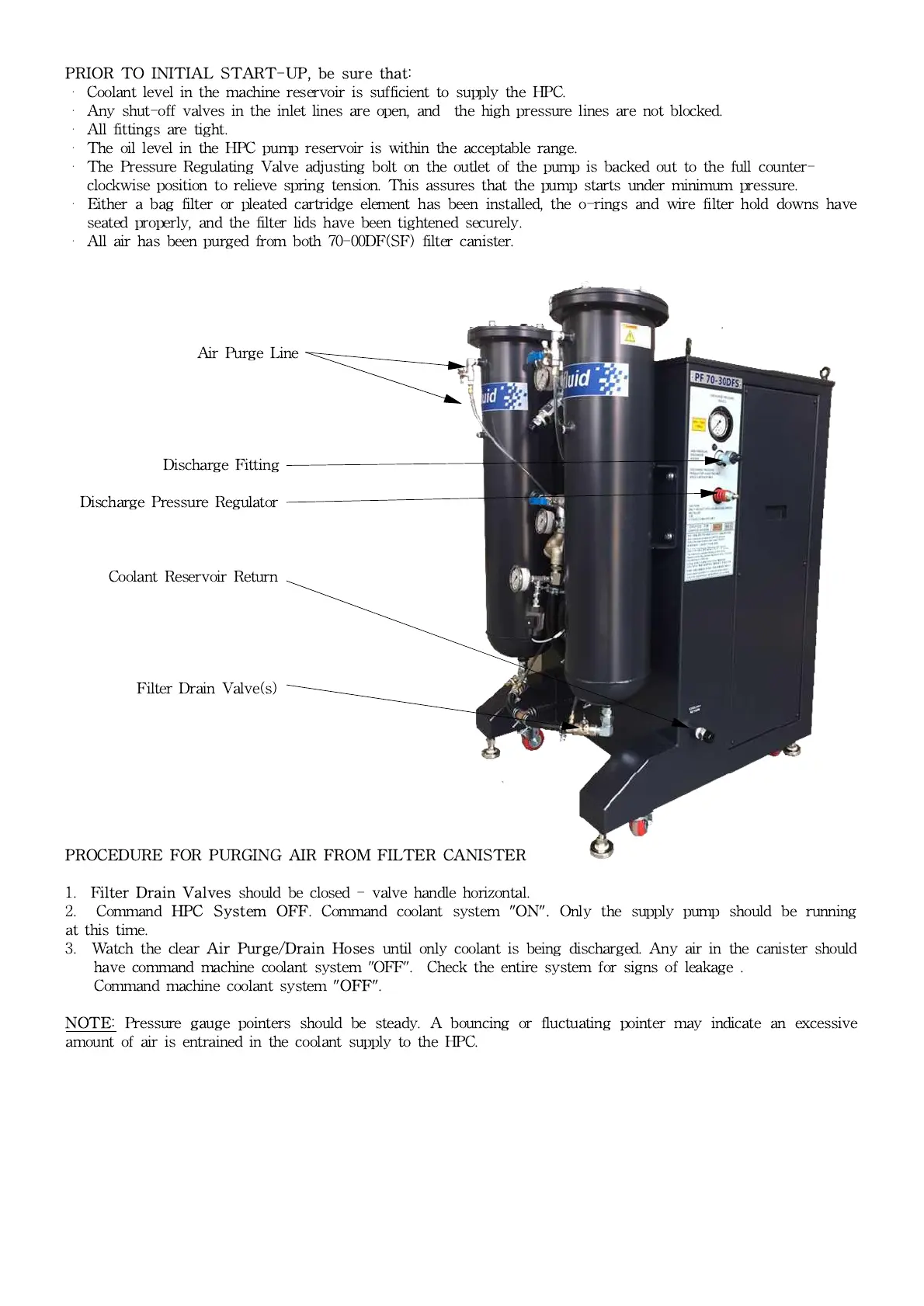

Air Purge Line

Discharge Fitting

Discharge Pressure Regulator

Coolant Reservoir Return

Filter Drain Valve(s)

PROCEDURE FOR PURGING AIR FROM FILTER CANISTER

1. F

ilter Drain Valves

should be closed - valve handle horizontal.

2. Command

HPC System OFF

. Command coolant system

"ON".

Only the supply pump should be running

at this time.

3. Watch the clear

Air Purge/Drain Hoses

until only coolant is being discharged. Any air in the canister should

have command machine coolant system "OFF". Check the entire system for signs of leakage .

Command machine coolant system

"OFF"

.

NOTE:

Pressure gauge pointers should be steady. A bouncing or fluctuating pointer may indicate an excessive

amount of air is entrained in the coolant supply to the HPC.

Loading...

Loading...