BM-16

This document is protected by copyrights.

Copying, using, or distributing without permission of PROMOTECH is prohibited.

11

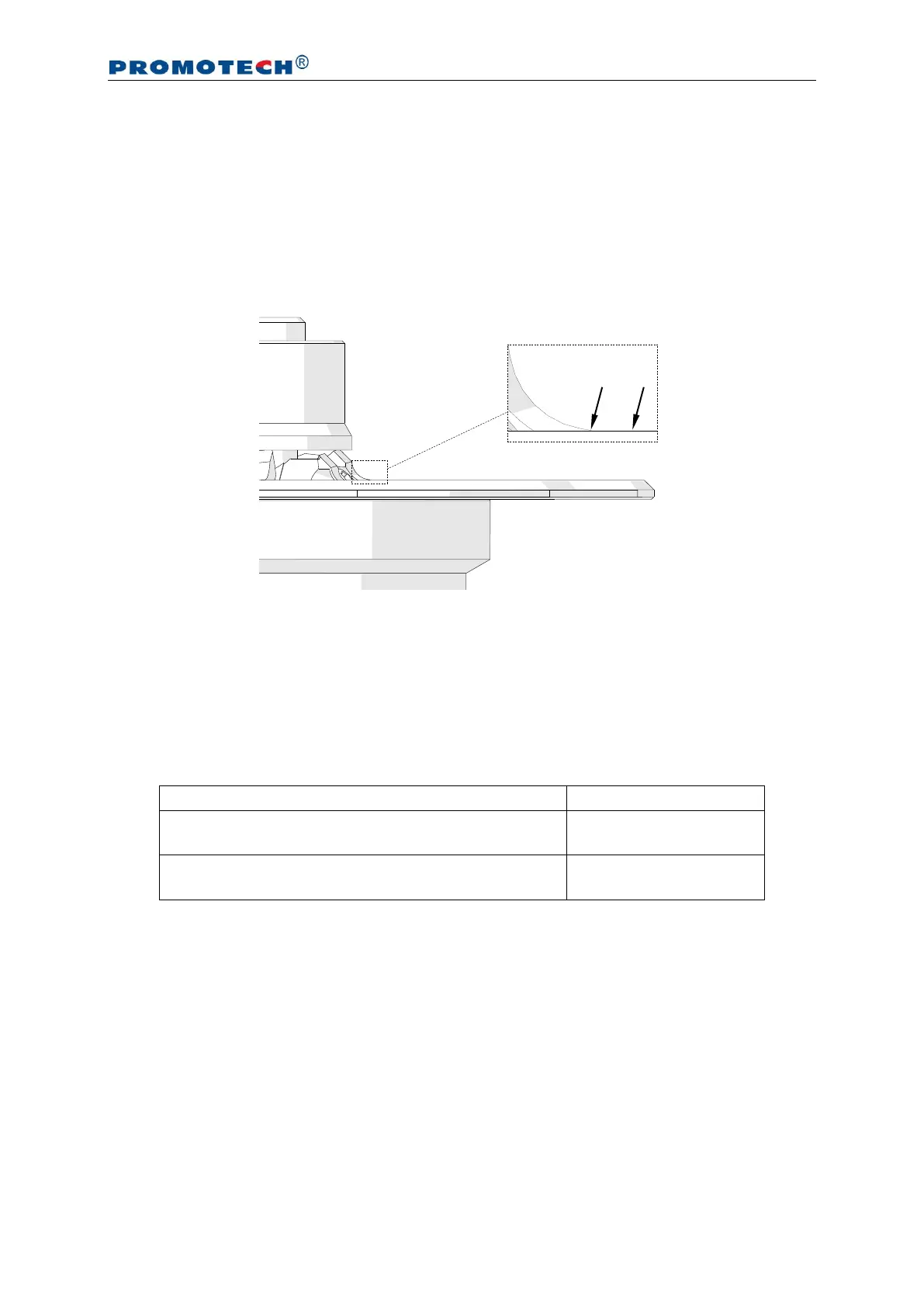

3.3. Adjusting the guide for bevelling with radius

Unplug the machine from the power source, and then in the manner described before

loosen the clamping screw and rotate the sleeve to set the surface 1 (Fig. 6) on the

same level as the radial cutting edge 2. You can also use an optional radius insert

positioner to set the guide properly. Next, re-tighten the clamping screw, and then

bevel a test edge and readjust the position of the guide if necessary.

Fig. 6. Guide adjusted for bevelling with radius

3.4. Preparing

Install a milling head with cutting inserts, and set the required bevel parameters.

Then, use the speed adjustment dial to set the speed corresponding to the type of

the workpiece (Tab. 2).

Aluminum, brass, plastics

Structural steel of standard quality, quality steel

Settings 3–5

(3100–4500 rpm)

Tab. 2. Recommended rotational speeds

The speed adjustment dial allows continuous control of the rotational speed in

the range of 1800–5850 rpm (settings 1–6). The relations between the setting and

speed are as follows: setting 1 – 1800 rpm, 2 – 2400 rpm, 3 – 3100 rpm, 4 – 3800 rpm,

5 – 4500 rpm, 6 – 5850 rpm.

When using structural steel of standard quality or quality steel, set the speed to

setting 4 and decrease the speed if intensive sparking occurs during operation.

Loading...

Loading...