BM-16

This document is protected by copyrights.

Copying, using, or distributing without permission of PROMOTECH is prohibited.

3

1. GENERAL INFORMATION

1.1. Application

The BM-16 is a bevelling machine designed to mill edges of plates and pipes made

of steel, aluminum alloys, brass, or plastics.

Depending on the milling head used the machine allows bevelling workpieces

with a thickness of at least 1.5 mm (0.06’’) at the angle of 20°, 22.5°, 27.5°, 30°, 37.5°,

40°, 45°, 50°, 55°, 60°, or 65° to the maximum bevel width of 16 mm (0.63’’). A radius

milling head allows bevelling with a radius of 2, 3, 4, or 5 mm. The minimum diameter

of a hole to be machined is 40 mm (1.57’’).

An optional guide allows bevelling pipes, sticker protects aluminum workpieces

against scratches, and worktable fixture allows bevelling small workpieces.

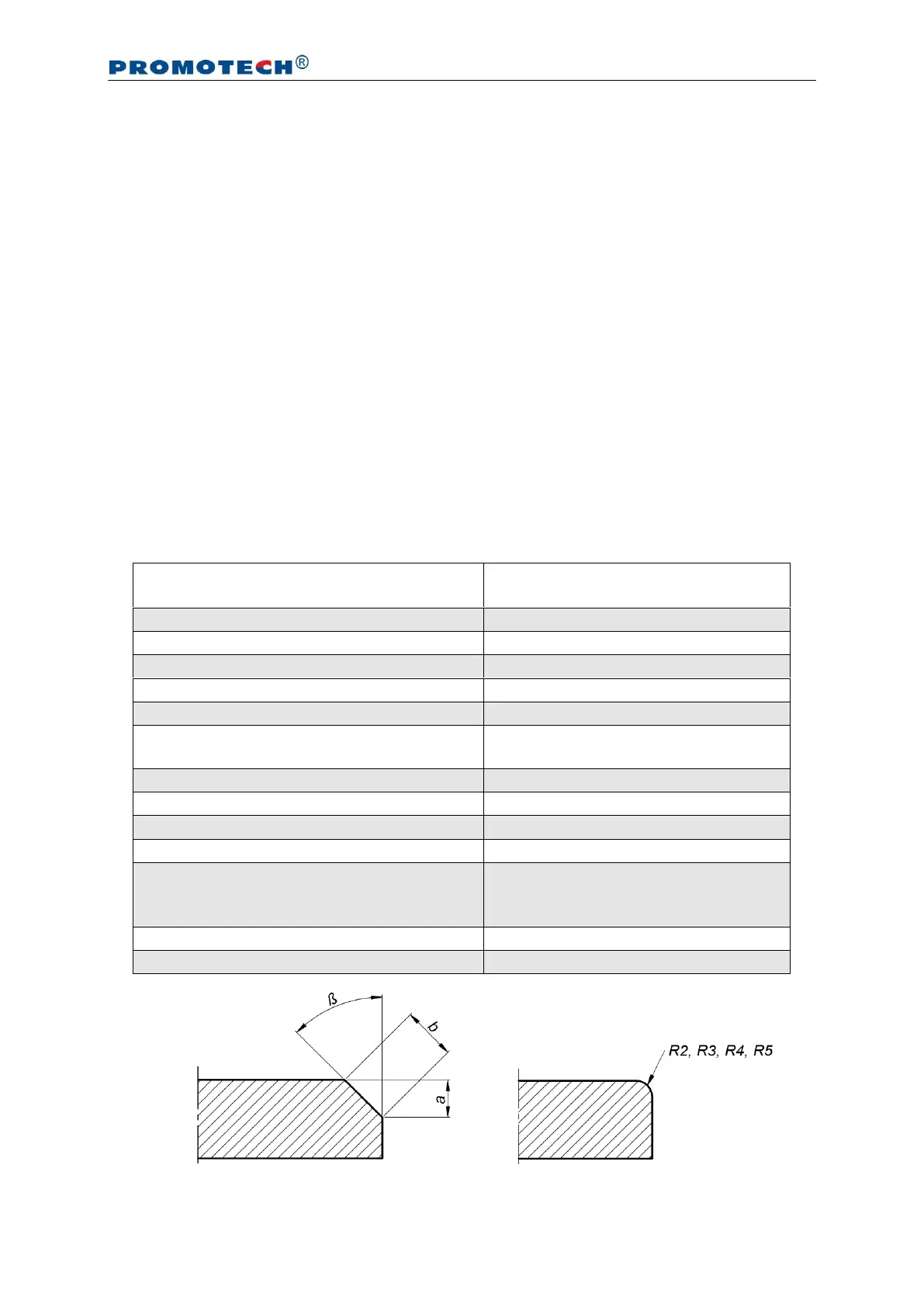

1.2. Technical data

1~ 220–240 V, 50–60 Hz

1~ 110–120 V, 50–60 Hz

Rotational speed (without load)

Bevel angle (ß, depends on the

milling head used)

20°, 22.5°, 27.5°, 30°, 37.5°, 40°, 45°,

50°, 55°, 60°, 65° (Fig. 1)

Minimum workpiece thickness for bevelling

2 mm, 3 mm, 4 mm, 5 mm (Fig. 1)

2.3 m/s

2

(7.5 ft/s

2

)

Machine harmful for health. Take

periodic breaks during operation.

Required ambient temperature

Weight (without milling head)

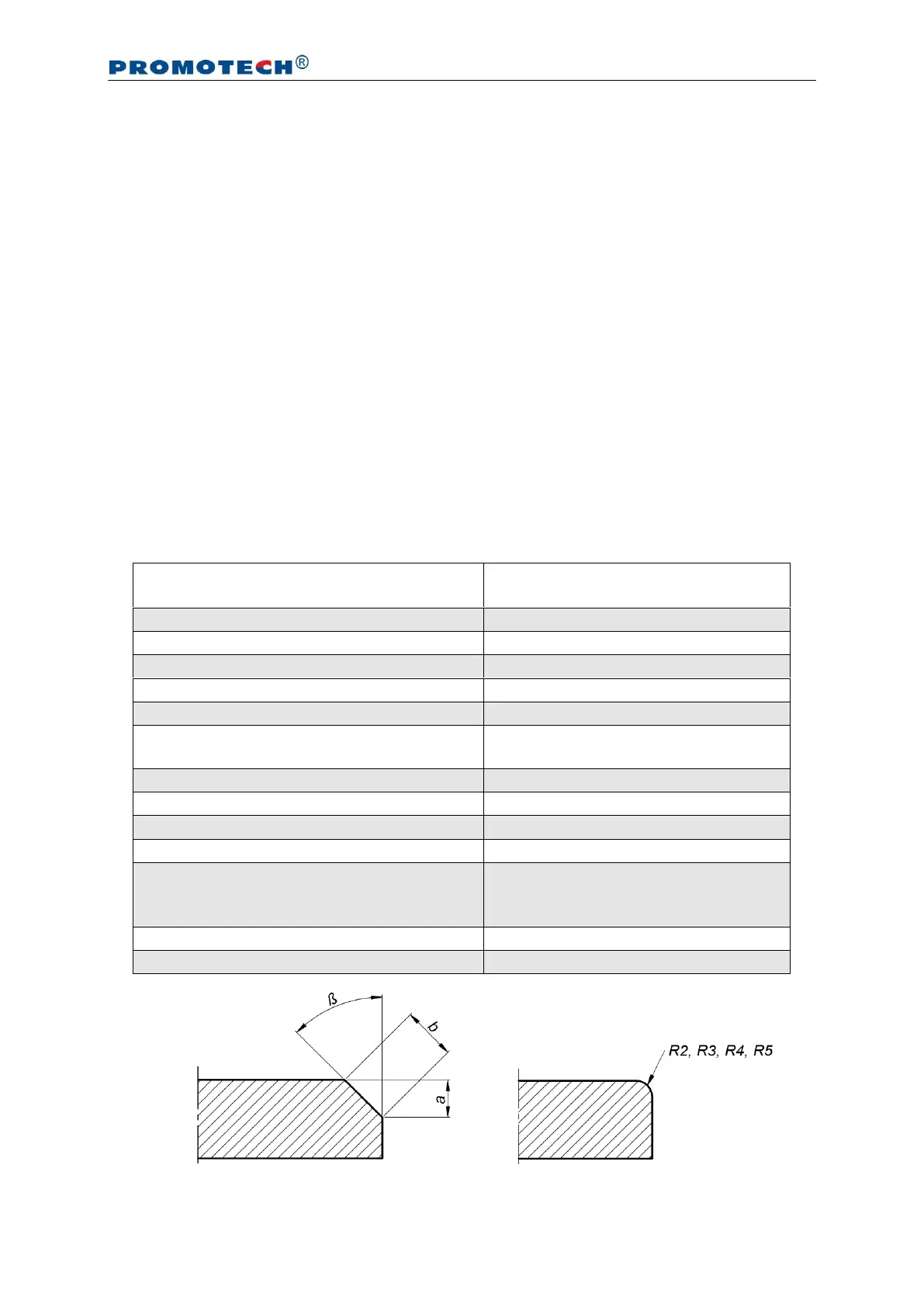

Fig. 1. Bevel dimensions

Loading...

Loading...