14

15

W W W . D Y E P A I N T B A L L . C O M W W W . D Y E P A I N T B A L L . C O M

The RIZE RIZE

RIZE

RIZE

RIZE

RIZE

RIZE RIZE

RIZE

RIZE

RIZE

RIZE

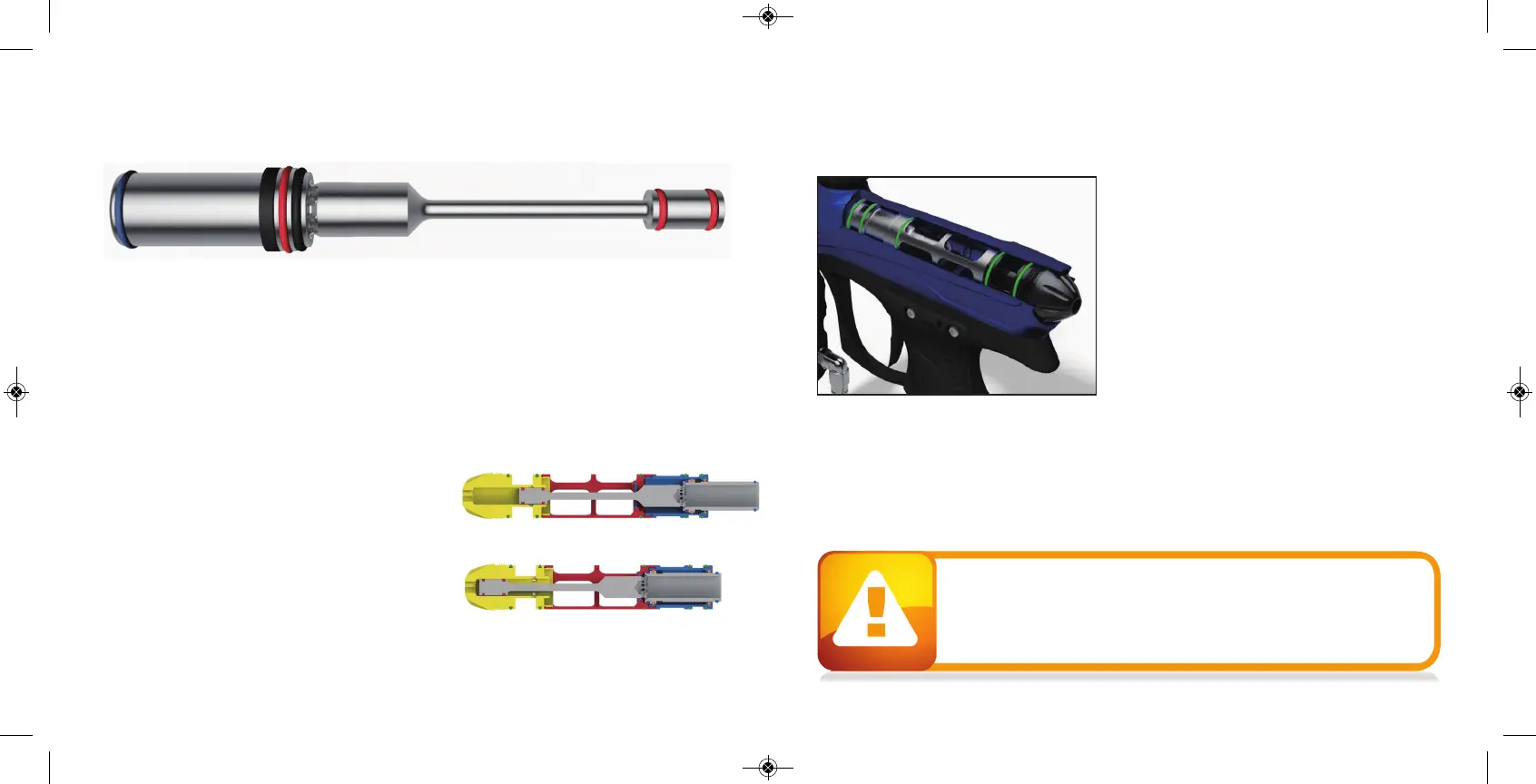

™ BOLT is the main component o f the ™ marker. In ord er to achieve the b est

possible p erformance of the RA IL™ it is essential that the ™ BOLT is kept clean, well lub ed

and in good working order.

The ™ BOLT should b e cleaned and re- lubed after each d ay of use.

There are 4 p arts in the ™ BOLT kit that mount together as one unit. To remove the ™

BOLT from yo ur ™, use a 1/ 4 "

allen key and turn

the Back Cap out 2 full turns co unter

clockwise. Now p ull o ut the comp lete RA IL™ b olt kit from the ™.

To dis- assemble the ™ BOLT kit you unthread the front most p art called the Can and the

Manifold from each other. Then p ull out the actual moving bolt from insid e these p ieces. Notice

that to sep arate the Can and the Bolt you need to remove

the b olt tip O- ring before the b olt

is able to slid e throug h

the C

an.

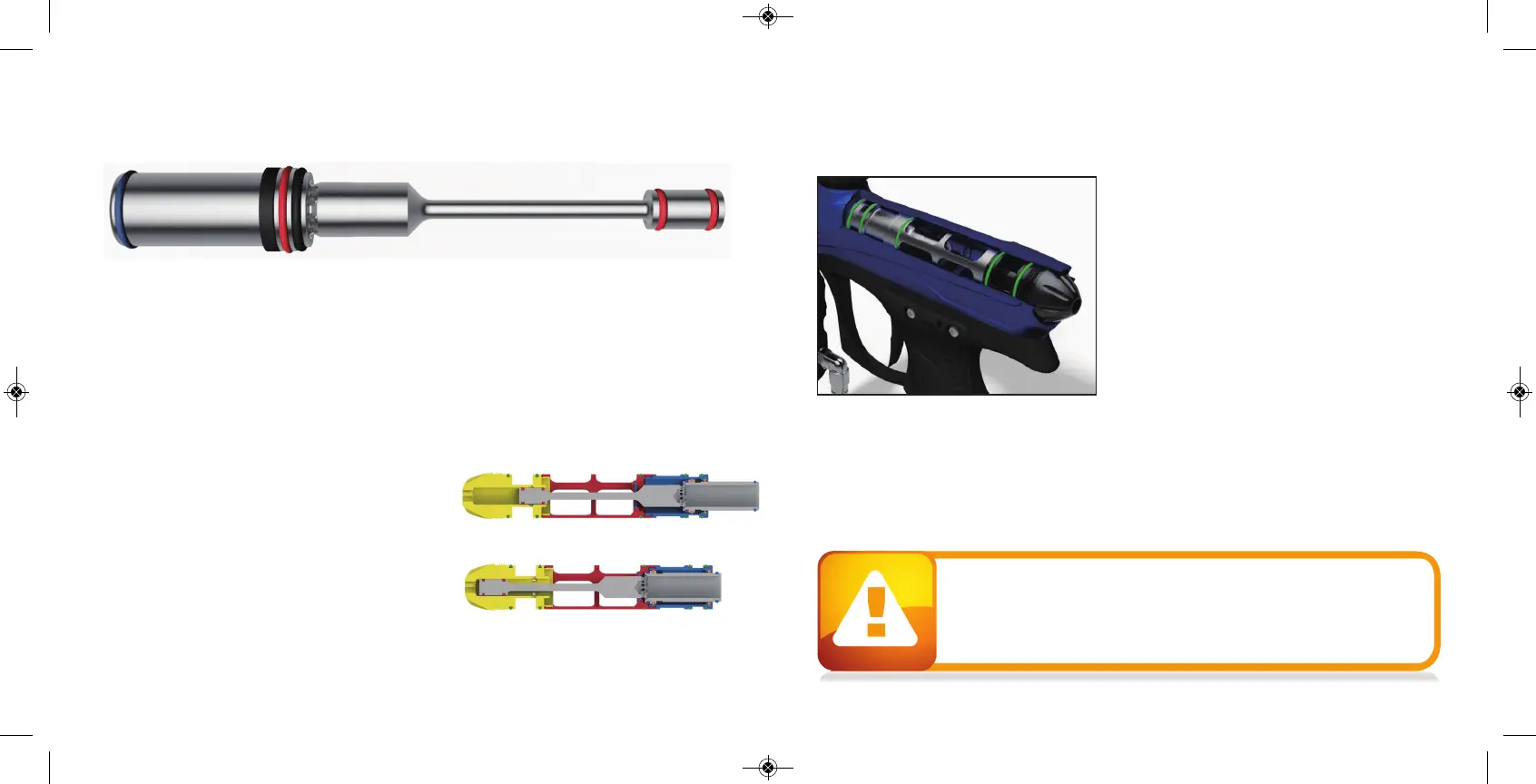

HOW DOES IT WORK

A ir is sup plied into two po ints on the ™ BOLT. In the

back air is routed through the Back Cap and Manifold

and fills up the sup ply chamb er around the Manifold . In

the front air is routed through the solenoid into the Can.

This air p ushes against the Sail o n the Bolt, which keep s

the b olt in the back p ositio n.

FORWARD POSITION

RIZE

™

BO LT

ASSEMBLY A ND MAI NTENA NC E

RIZE

™

BO LT

ASSEMBLY A ND MAI NTENA NC E

When the ™ is fired the solenoid is actuated

and the air insid e the Can is exhausted out. The

force created by the air insid e the supp ly chamb er

causes the b olt to start moving forward . Once the

bolt has moved ab out half way forward , the tail of

the b olt closes the inp ut into the supp ly chamb er.

Once the Bolt reaches the forward p oint, the valve

of the ™ B

olt is opened and air inside the

supply chamber g o

es throug h the Bolt and fires

the p aintball. After this the solenoid is d e-

activated and g as is sup plied through the

solenoid b ack into the Can. This causes the Bolt

to return to the b ack position and the sup ply

chamb er to be re- charg ed.

When servicing your marker:

• Make sure your hopper is removed from the marker.

• Make sure there are no paintballs in the breech of the marker.

• Always remove the air supply and relieve all gas pressure in the marker

before disassembly.

• When using the marker in temperatures below 50° Fahrenheit it may be

necessary to lube the RAIL™ bolt more frequently.

BACK POSITION

Loading...

Loading...