ChapTEr 1: prE-INSTallaTION

17

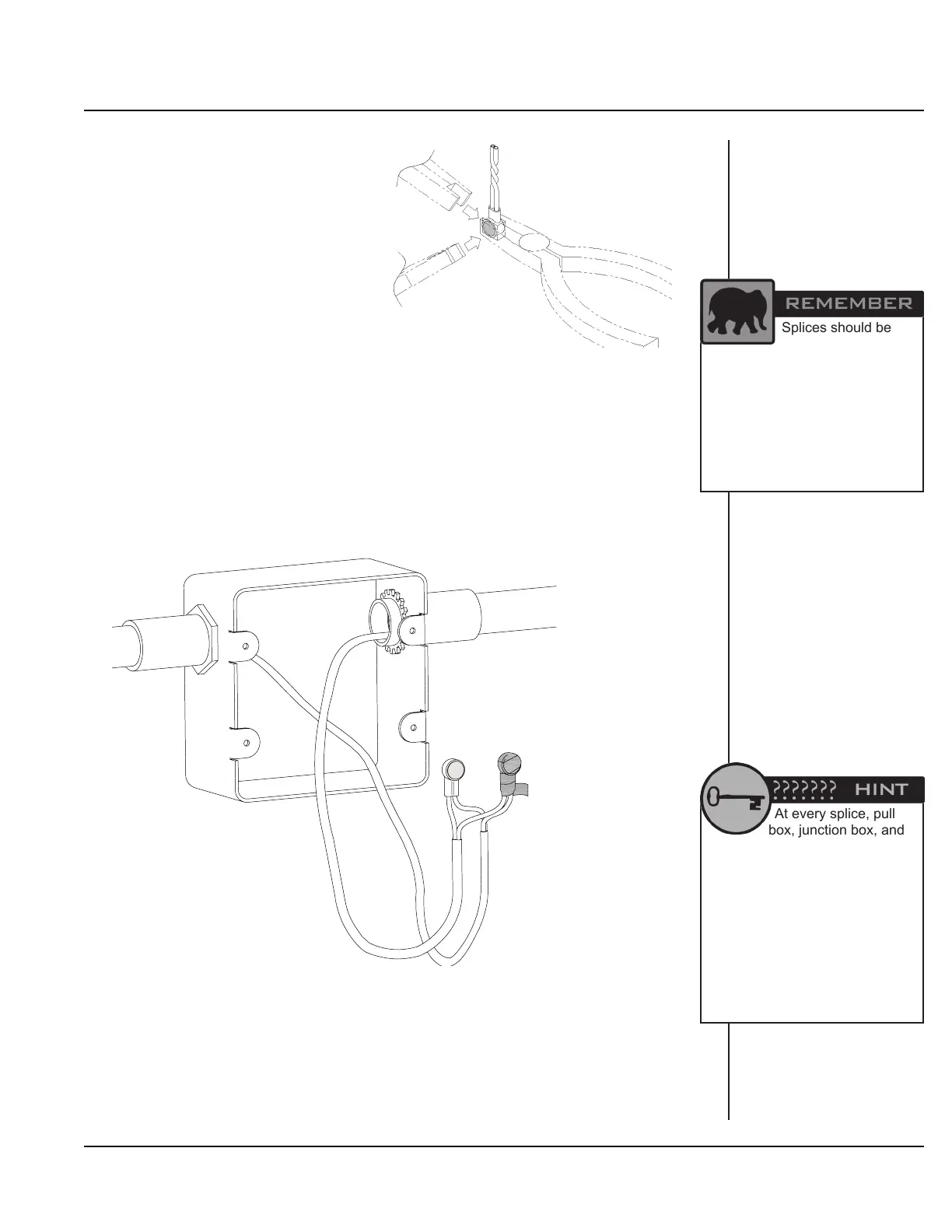

3. Verify that the wires are

both seated completely

at the bottom of the

connector. Then, using

a 3M E9-Y crimping

tool, crimp down the

button on the connector.

The crimping tool can

be purchased from PTI

Security Systems. For

best results, crimp each

connector three times in different places around the edge of

the button. Verify that the button is evenly crimped all the way

around and that it does not pop back up on one side.

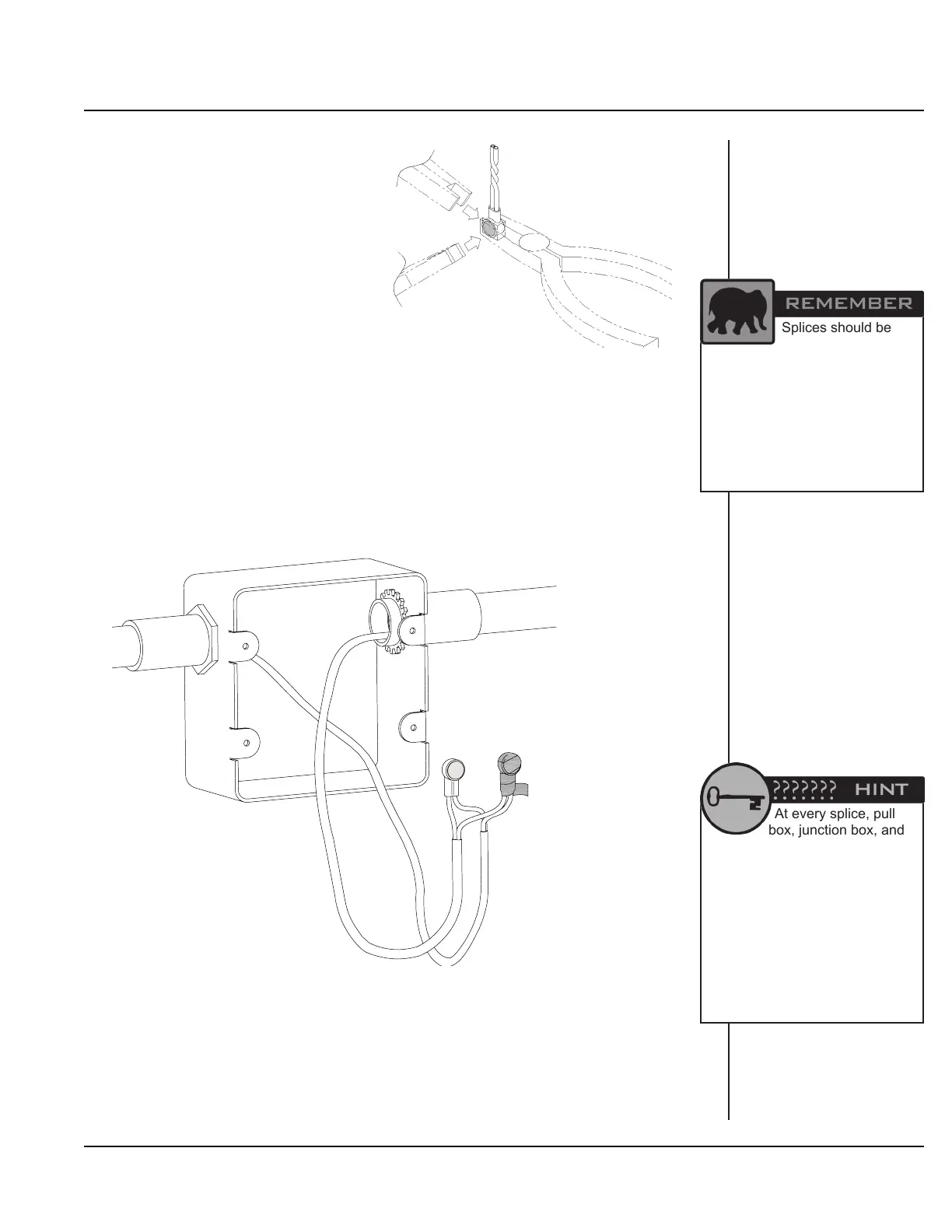

4. Wrap electrical tape around the splice and partway up the

wires to help seal and protect the connection. Place a wire tag

on the wires inside the junction box, identifying what the wire is

connected to at each end.

Splices should be

kept to a minimum or

eliminated completely from a site

whenever possible.

Any splices that must be done

should be made in an all-

weather electrical junction box

that is mounted above ground in

accordance with electrical code.

At every splice, pull

box, junction box, and

AI device connection, a ‘service

loop’ should be made. This is an

extra 1’ – 2’ of wire that is pulled

to allow for future maintenance

or correction of the splice or

connection. After the splice or

connection is made, the extra wire

is neatly coiled in the box or slid

back into the gooseneck or wall

behind the device.

Loading...

Loading...