PAGE 12

FAILURE TO FOLLOW OPERATING INSTRUCTIONS WILL

RESULT IN PROPERTY DAMAGE, SEVERE INJURY OR DEATH.

After the PULLMASTER planetary winch has been installed in accordance with the INSTALLATION INSTRUCTIONS,

the wire rope can be fastened to the cable drum.

IMPORTANT: The ropes, chains, slings, etc. are not part of the winch and are not covered by this manual.

Refer to the manufacturer's handling, inspection and maintenance recommendations to avoid

potential accidents. For selection of ropes, etc. please check the following product standards:

DIN 15020, prEN 818-1/9, prEN 1492-1/2, prEN 1677-1/3 and other relevant product standards.

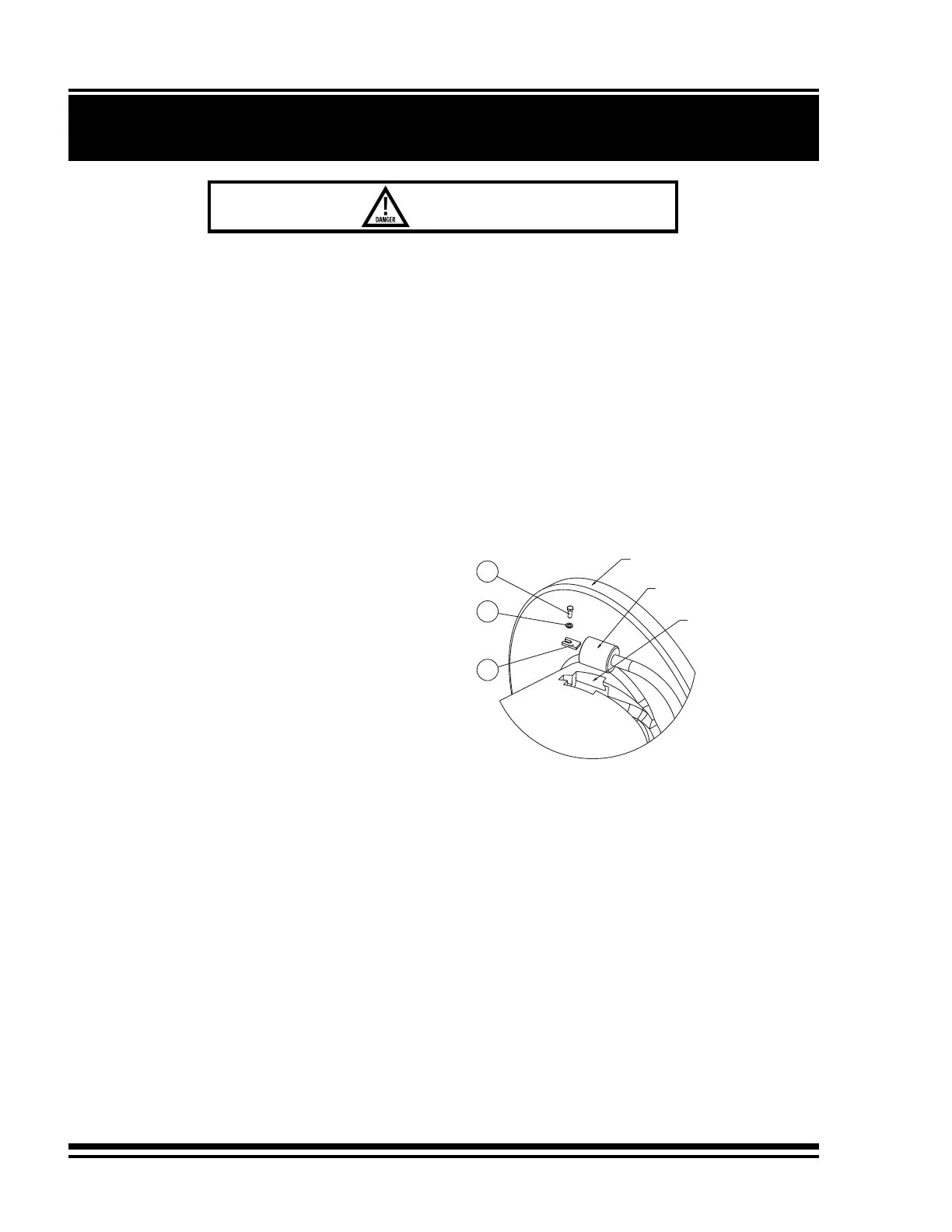

1) The cable drum of the PULLMASTER planetary winch has two pockets for wire rope ferrules, one for clockwise

and one for counterclockwise hoisting. Standard rotation for hoisting is clockwise when looking at the hydraulic

motor of the unit. It is critical to select the ferrule pocket which will permit winding of the wire rope on the drum

in the correct direction of rotation. If the wire rope is wound on the cable drum in the wrong direction of rotation,

the winch will have no braking capacity. Each winch is shipped from the factory with a warning label on the drum

indicating the correct cable anchor (ferrule) pocket and direction of hoisting.

OPERATING INSTRUCTIONS

DANGER

3) The winch operation is controlled by a single control valve lever which has a forward, a reverse and a neutral

position. Speed control in either direction is obtained by modulation of the control valve lever. Maximum line

speed in either direction is obtained when the control valve lever is moved as far as it can go. The disc brake

of the winch will come on automatically when the winch control lever is returned to neutral.

4) Always warm up equipment prior to operating winch, particularly in low ambient temperature. Circulate hydraulic

oil through the winch control valve for several minutes to warm the hydraulic system. To prime the winch with

warm oil, operate the winch at slow speed, forward and reverse, several times.

5) Prevent corrosion damage to winch interior. If not used regularly, run winch up and down at least once every

two weeks.

6) To ensure proper winch installation and function, raise and lower a full test load to a safe height before using

winch for regular operation at the start of each shift.

If, after a new installation, the winch does not function properly, refer to the TROUBLESHOOTING section of

this manual.

SI1013-75

WIRE ROPE INSTALLATION

Clockwise hoisting winch shown.

(Use ferrule pocket on opposite side of

drum for counterclockwise hoisting winch.)

Attach ferrule to rope per manufacturers

instructions and install ferrule into drum pocket.

Pull rope tight and install retainer plate item No,

501. Retainer plate is suitable for ferrule

lengths from 2 3/4" to 3 3/16".

2) For safety the cable drum requires 5 wraps of wire rope.

(FOR CLOCKWISE ROTATION)

CLOSEST TO MOTOR

FERRULE POCKET

FERRULE

CABLE DRUM FLANGE

501

503

502

354 REV.051117

Loading...

Loading...