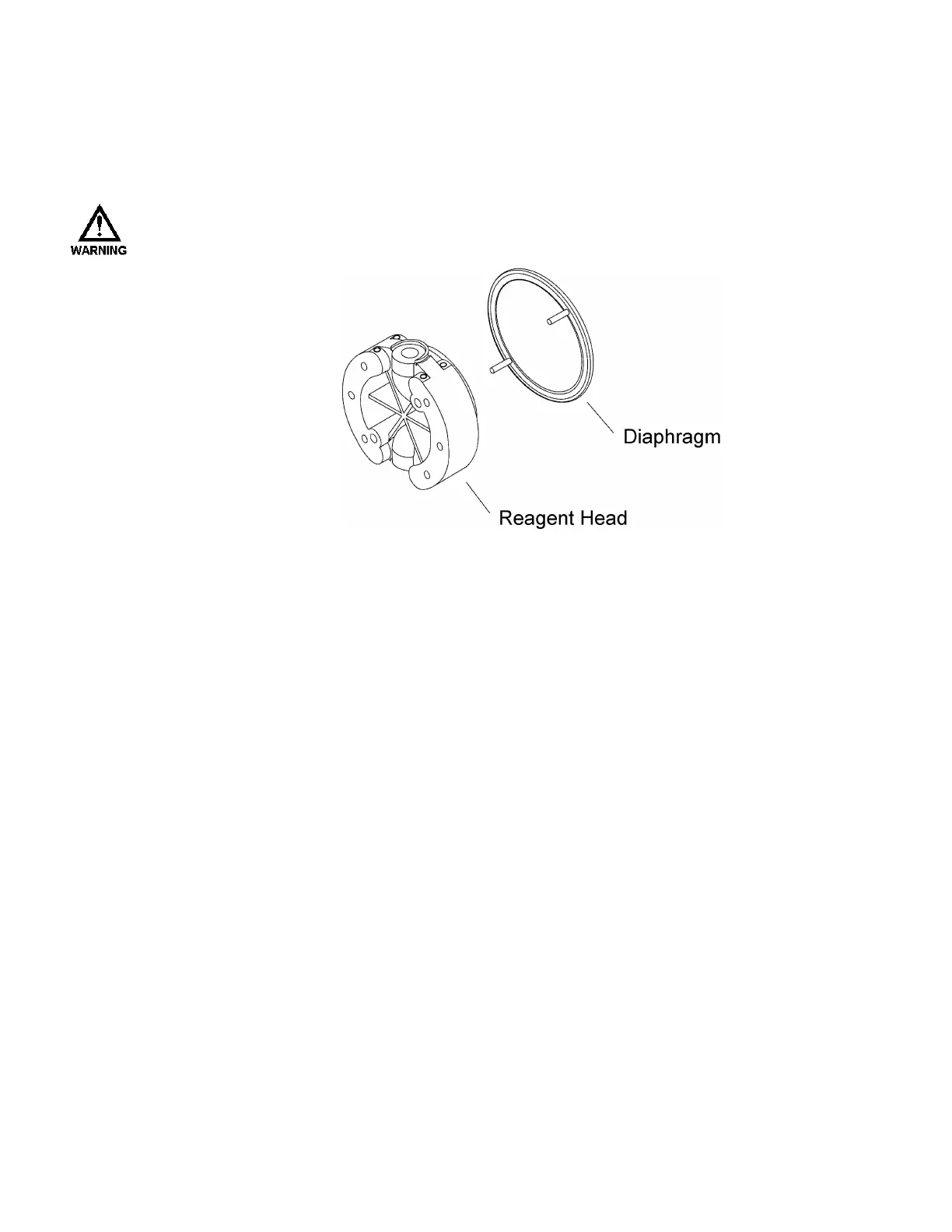

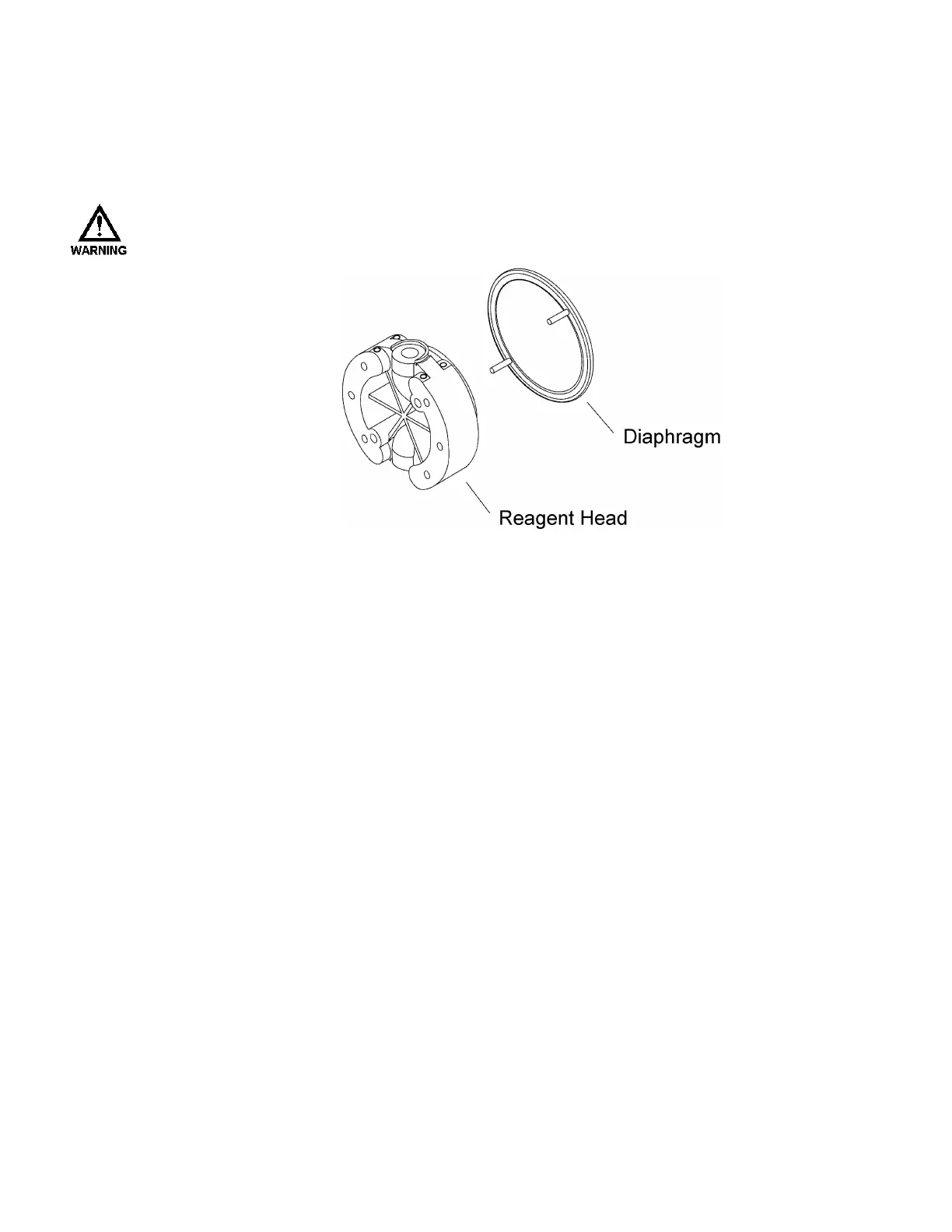

11.5 PULSALARM LEAK DETECTION DIAPHRAGM

MAINTENANCE

After diaphragm failure, pressurized process fluid can be present in any part of the PULSAlarm

leak detection vacuum system. Take appropriate precautions and handle with care.

Figure 27

11.5.1 Leak Detection Diaphragm Removal

Use the following procedure to remove the Leak Detection Diaphragm:

1. Disconnect the power source to the drive motor.

2. Relieve all pressure from the piping system, and close the inlet and outlet shutoff valves

3. Take all precautions to prevent environmental and personnel exposure to hazardous

materials.

4. Place a suitable container underneath the pump head to catch any liquid leakage.

5. Disconnect process piping and drain any process liquid, following material safety

precautions.

6. Remove all but one top reagent head bolt. Oil will leak out between the pump head and

reagent head as the bolts are loosened.

7. Tilt the head and pour out any liquids retained by the check valves into a suitable container,

continuing to follow safety precautions as appropriate.

8. Remove the alarm switch assembly or pressure gauge from the reagent head.

9. Remove the bleed valve assembly and flat gasket from the reagent head.

10. Rinse or clean the reagent head with an appropriate material.

11. Remove the diaphragm by running a blunt blade along the periphery and prying it out.

Loading...

Loading...