Document No.: 1P0446-1 Rev. B, April 7, 2014

Each flowmeter has a solenoid valve that shuts off the flow of gas, thus retaining the setting of the

respective flowmeter for a subsequent process. For added safety, the gas solenoid for each

flowmeter will not allow gas to flow into the chamber until all interlocks are activated.

Note: The inlet pressure from the gas bottle should be regulated to 10 psig before the gas is

introduced to the back of the IoN 3 MHz.

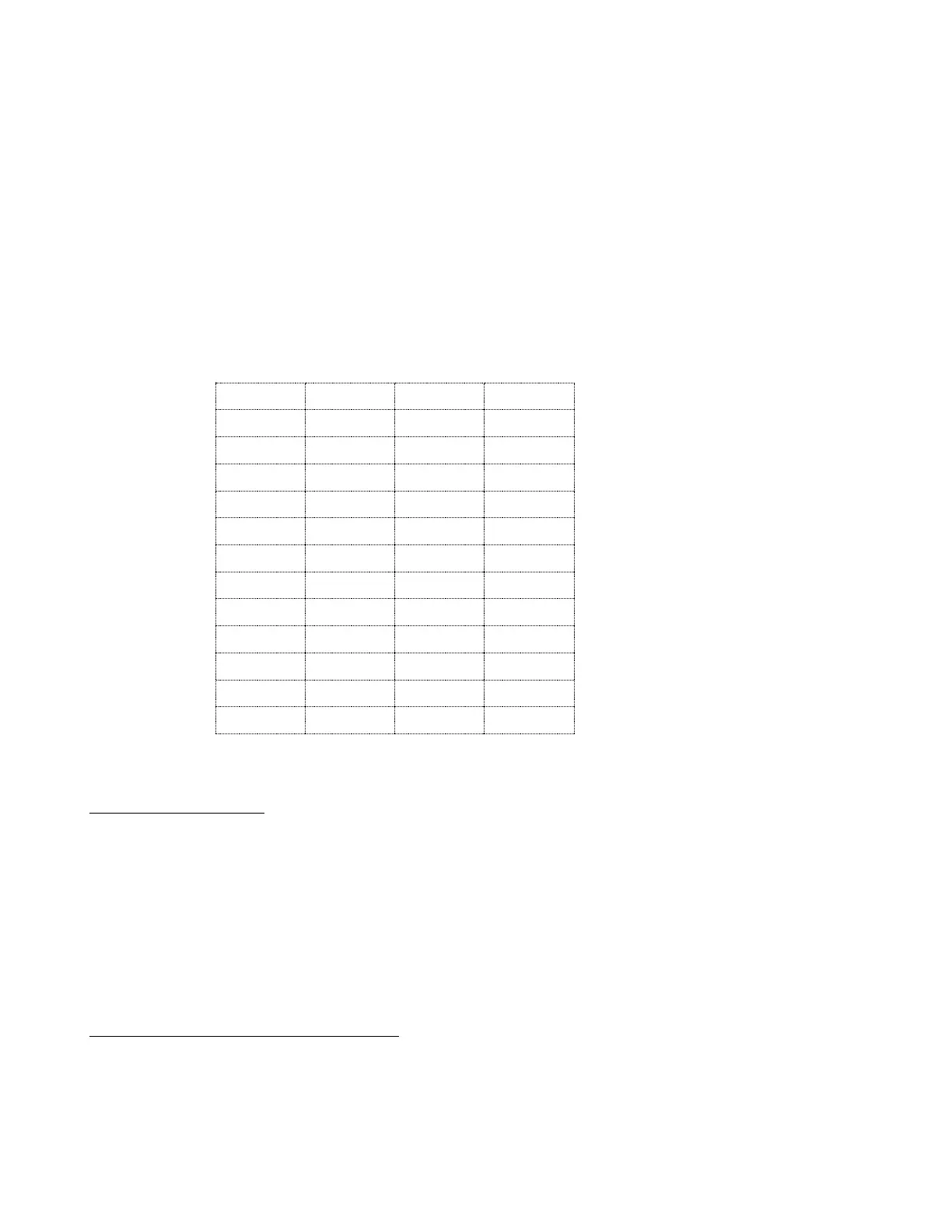

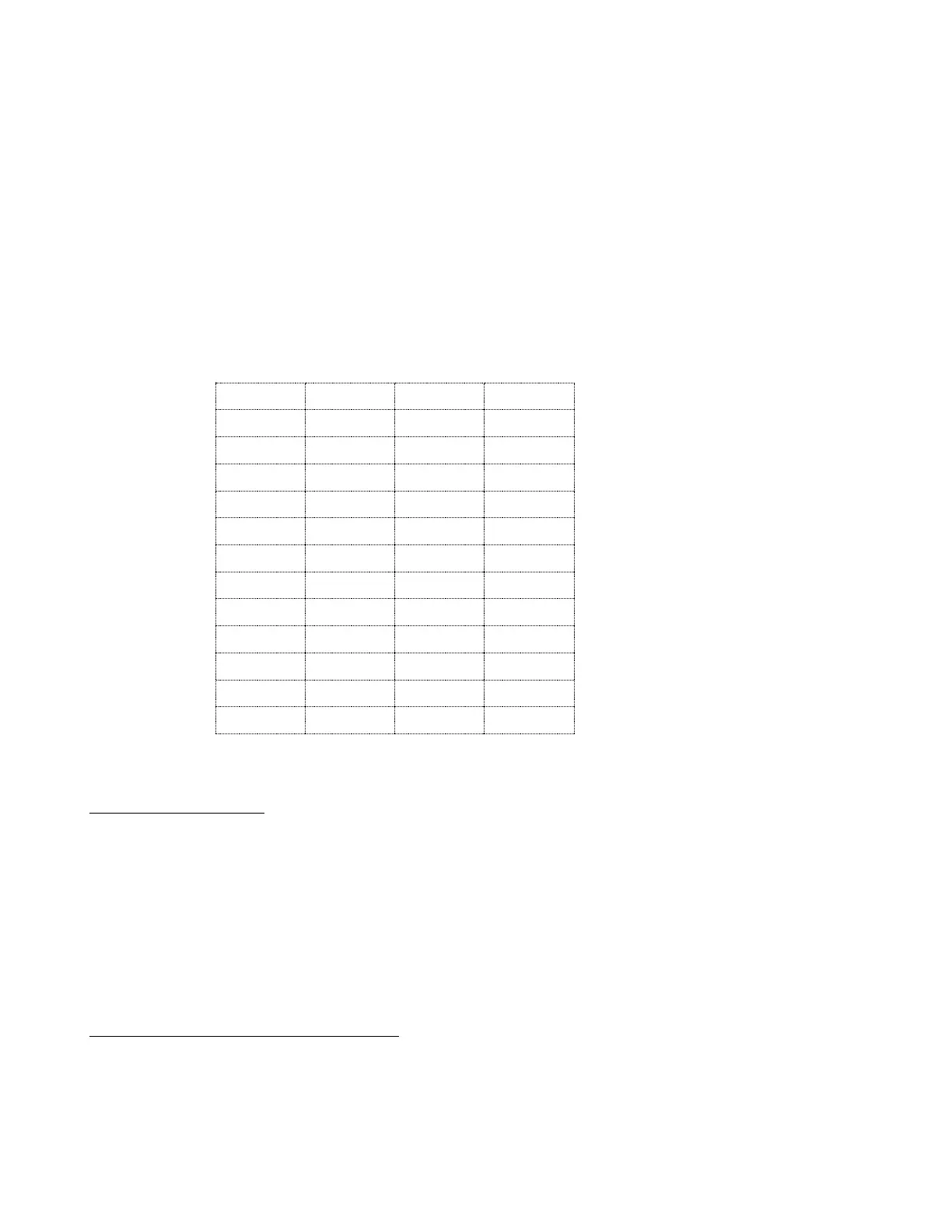

Table 1 Flowmeter Calibration Data

float material: GLASS BALL float density: 2.55 G/CC

metered Temp: 70ºF metered Pressure: 10 PSIG

tube #A-125-3 units: CC/MIN

PRESSURE INDICATOR

The IoN 3 MHz will report the actual pressure reading (accurate within 20 mTorr) on the front

PRESSURE display. This pressure reading will give a reading of the chamber pressure. After the

PROCESS START button has been depressed, the pressure sensor signals the system logic to start the

process (RF and gas flow) when a crossover pressure of .35 Torr (350mT) has been achieved.

The PRESSURE indicator does not display a reading until reaching a pressure below 2 Torr. The

pressure sensor has a range of around .01 Torr (10 mTorr) to 2 Torr. Normal operating pressure will

range between .5 Torr (500mT) and 1.2 Torr.

DIAGNOSTIC LED DISPLAY INDICATORS

Five LED display indicators are located on the lower front panel of the IoN 3 MHz system. When

illuminated, the LEDs provide the user confirmation that all the system modules are functioning

correctly.

Loading...

Loading...