Section III - QCS450

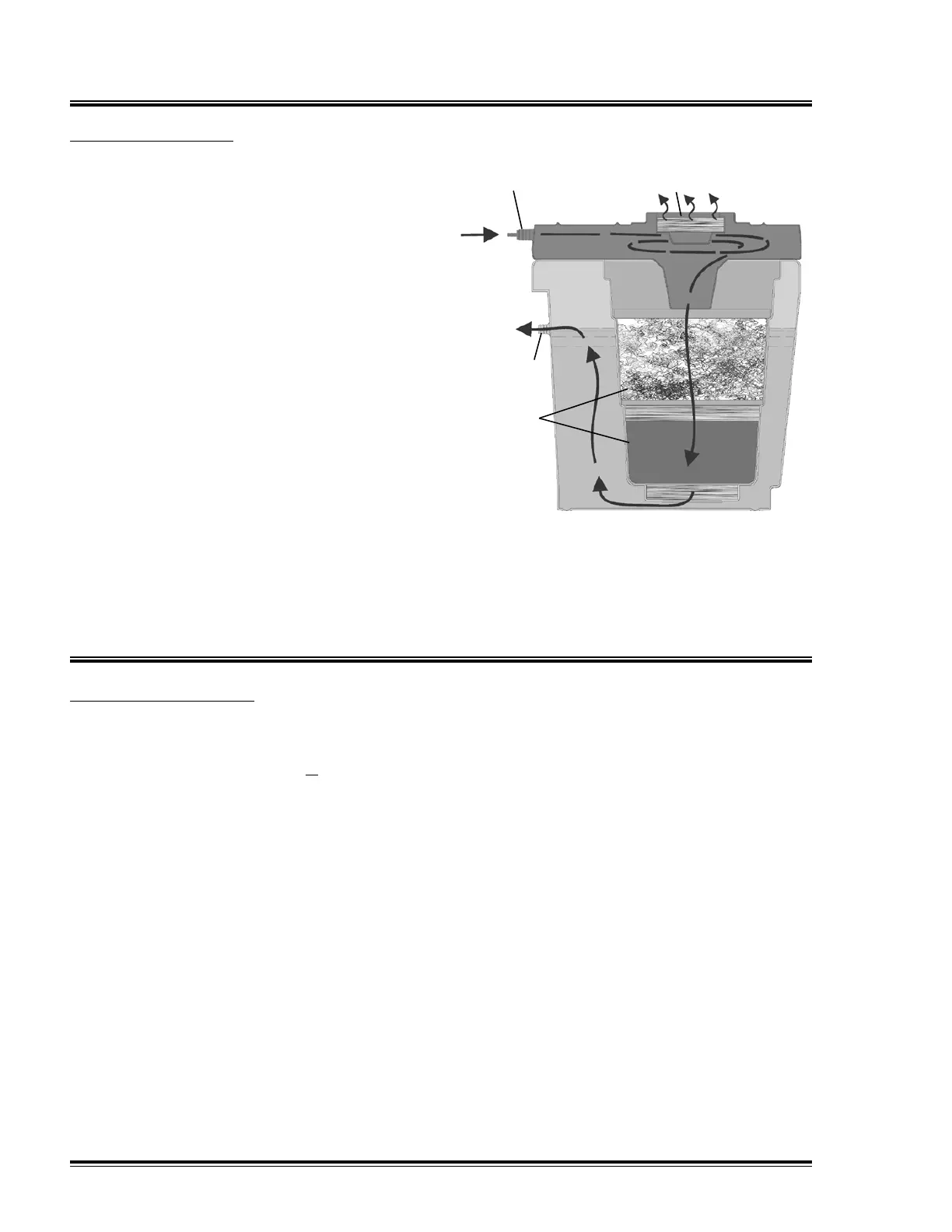

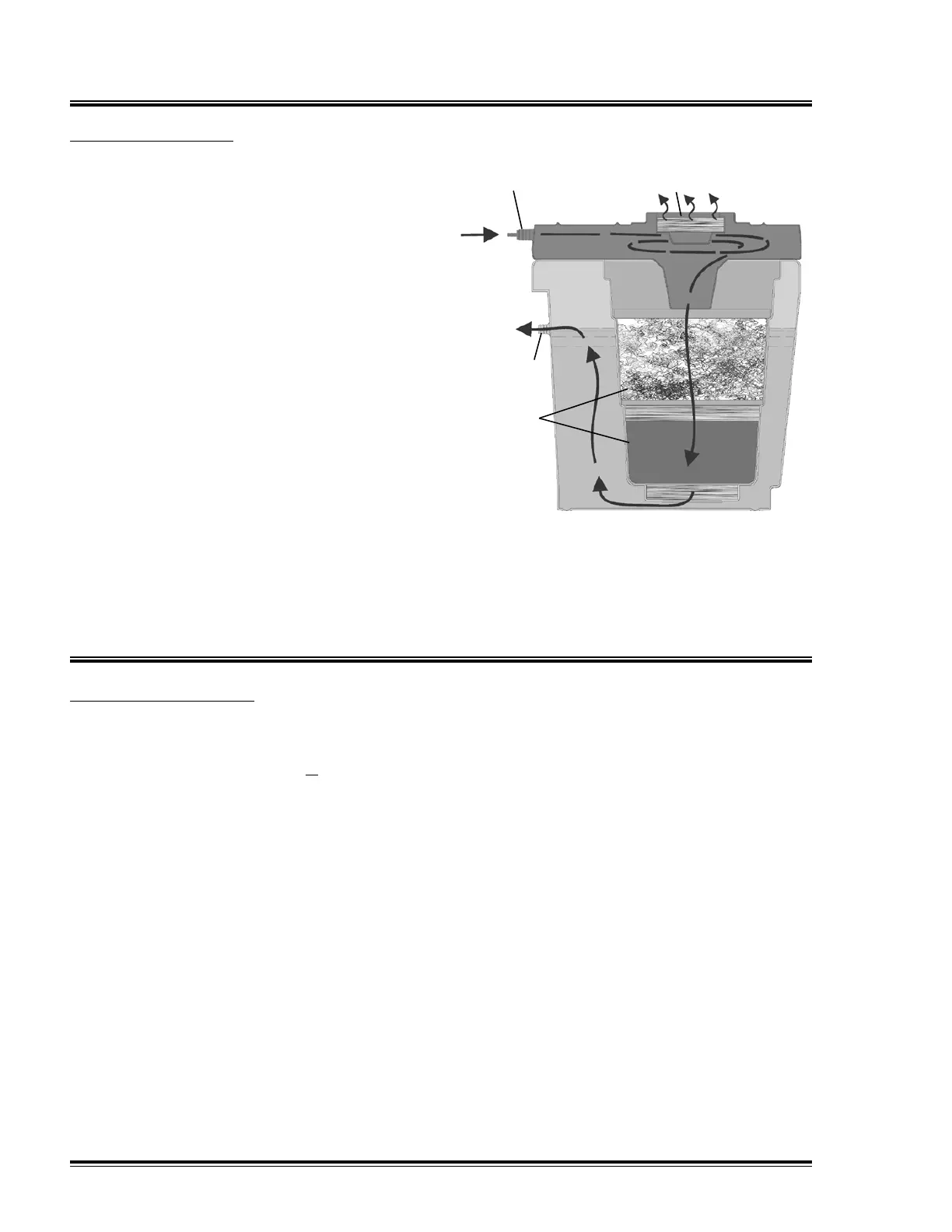

QCS450 Function

Oil contaminated condensate can be

discharged under pressure into the

QCS450 oil/water separator (maximum

system pressure 16 bar).

Overpressure is reduced in the pressure

relief chamber (2) without creating

turbulence in the separation container.

The calmed condensate flows into the filter

stage where it passes slowly through the

cartridge.

The first stage removes large oil drops and

dirt particles, the second stage removes

small oil droplets and the third stage

removes residual mineral hydrocarbons.

The clean water is discharged through the

outlet connection (4).

1 CONDENSATE INLET

2 PRESSURE RELIEF CHAMBER

3 FILTER CARTRIDGE

4 WATER OUTLET

QCS450 Installation

Installation Site

A sealed floor or spill basin (>18 gallons or

69 liters) is required. It is crucial to ensure

that untreated condensate or oil cannot

get into the sewer system in the event of

damage.

The floor area must be stable and level

(maximum inclination 1°) to ensure reliable

functioning of the QCS.

Corrected size of the spill basin (01/19/09).

12 Quincy Compressor-QCS High Efficiency Emulsion Separators

Loading...

Loading...