PREVENTIVE MAINTENANCE

To ensure

that

the

Disk

Drive

operates at its design poten-

tial,

the

only scheduled preventive maintenance required

is

periodic cleaning

of

the magnetic recording head.

Mechanical and electrical adjustment details are provided

for further service

as

a result

of

disassembly

or

repair.

CLEANING THE

HEAD

To clean the magnetic head,

use

a lint-free cloth

or

cotton

swab moistened with

91%

Isopropyl alcohol.

Wipe

the head

carefully

to

remove

all

accumulated oxide and dirt.

Dry

the

head using a lint-free cloth.

CAUTION: Rough or abrasive cloth should not

be

used

to

clean

the

magnetic recording head.

Use

of

cleaning solvents

other than

91

% Isopropyl alcohol may damage

the

head.

Extreme care must

be

exercised

to

prevent the heads from

being damaged (i.e., scratching, banging together, etc.).

ALIGNMENT AND ADJUSTMENT

To perform the alignment and adjustment procedures,

you

will

require the following equipment:

* 30

MHz

Dual

Trace Triggered Sweep Scope

* 5

1/4"

Alignment Diskette

* 5 1

/4"

Blank "scratch" Diskette

DRIVE MOTOR MAINTENANCE

Long

Term Motor Speed Adjustment

1. Check power

to

unit. (+12

VDC

+

@.6V,

and

+5

VDC

±

@.25V.)

2. Insert a blank diskette and activate the drive.

3. Under fluorescent lighting, observe the speed disk

on the spindle pulley. For 60

Hz

operation

the

outer ring on the speed disk should appear station-

ary. For

5@

Hz

operation the inner ring should

appear stationary.

4.

If

the

speed disk does not appear stationary, adjust

R4, located on the Servo

PCB,

until

the

disk

appears stationary.

5.

If

motor speed cannot

be

adjusted, repair Servo

PCB

or motor

as

required.

108

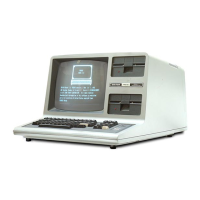

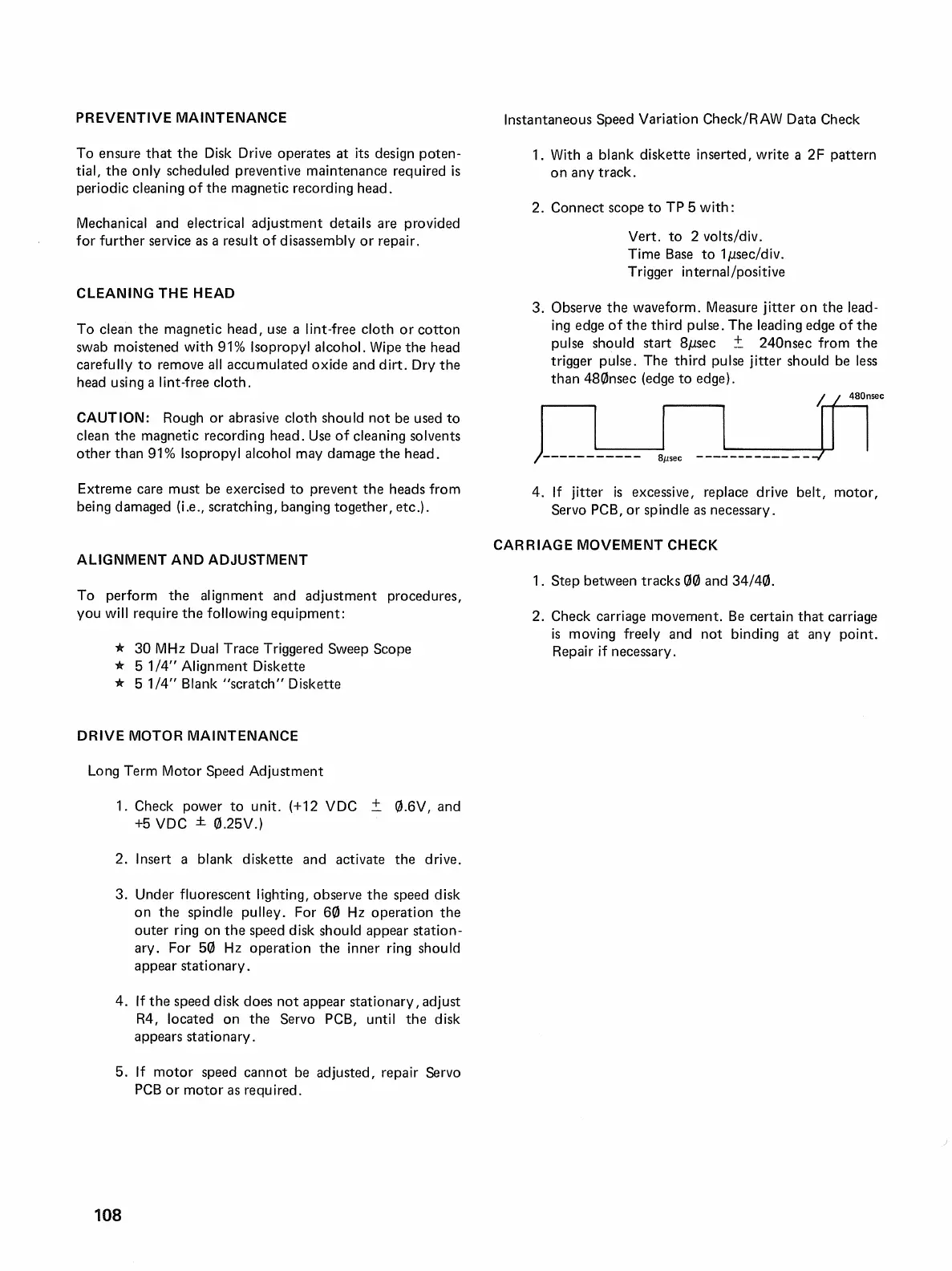

Instantaneous Speed Variation Check/RAW Data Check

1.

With

a blank diskette inserted, write a 2F pattern

on any track.

2. Connect scope

to

TP 5 with:

Vert.

to

2 volts/div.

Time

Base

to

1,usec/div.

Trigger internal/positive

3. Observe

the

waveform. Measure jitter

on

the lead-

ing

edge

of

the

third pulse. The leading edge

of

the

pulse should start

8,usec

± 240nsec from

the

trigger pulse. The third pulse jitter should

be

less

than 480nsec (edge to edge).

lflre,

L--J-----

L,

__

J _

4.

If

jitter

is

excessive, replace drive belt, motor,

Servo

PCB,

or spindle

as

necessary.

CARRIAGE MOVEMENT CHECK

1. Step between tracks

00

and 34/40.

2. Check carriage movement.

Be

certain

that

carriage

is

moving freely and not binding at any point.

Repair

if

necessary.

Loading...

Loading...