tube to drive pinion down hard enough

to seat O-ring (item 52) into groove in

bottom of pinion gear.

C. Slide pinion gear up toward end of

shaft so that there is a 1-13/16”

distance from top of gear to cast

surface below gear. Tighten setscrew

(item 36) securely enough to prevent

pinion gear from moving on motor

shaft.

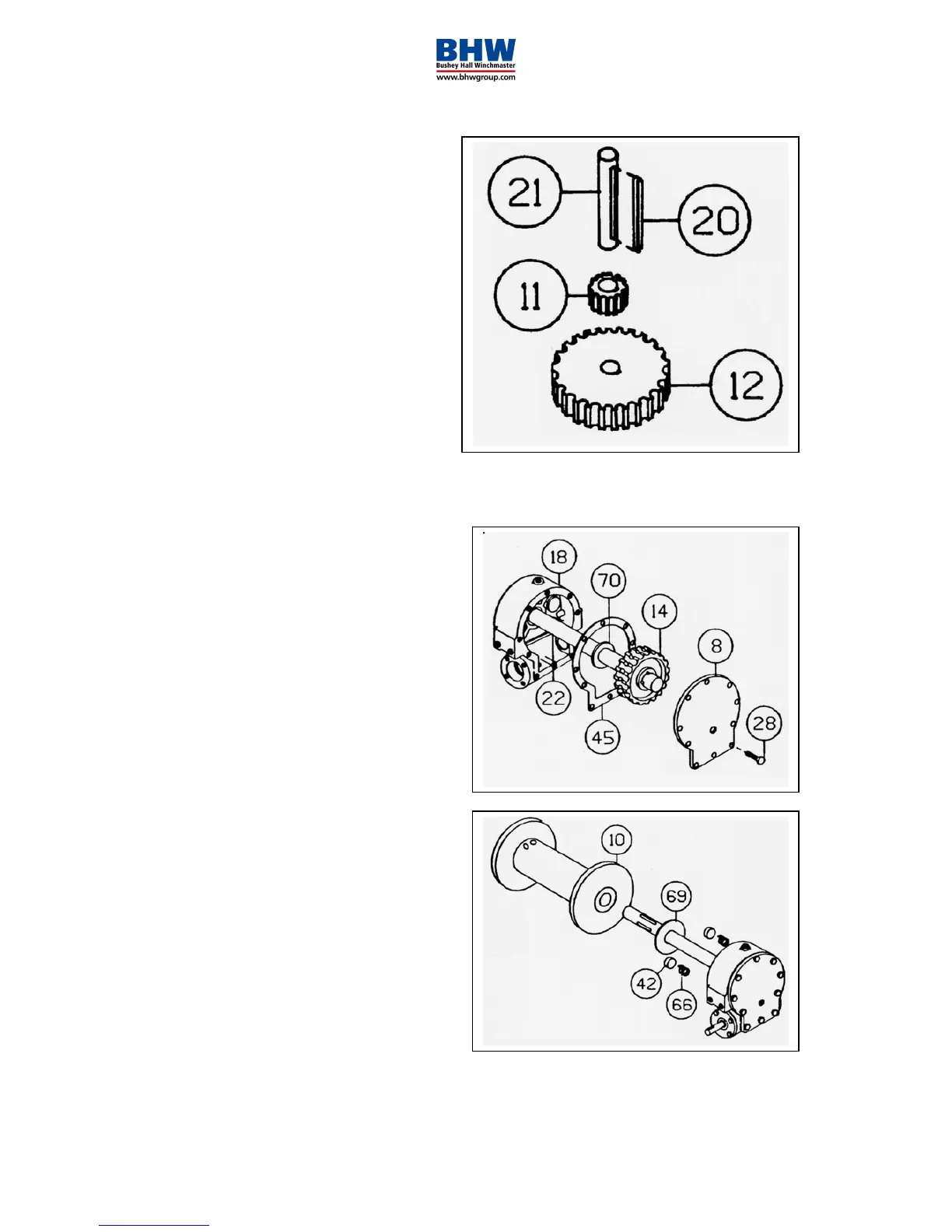

13. Check gears of spur gear shaft

assembly for signs of wear, replace if

necessary. Press old gears from shaft

(item 21). Tap key (item 20) into

keyway of shaft (item 21). Press shaft

through gears so that gears are

centred on shaft and key.

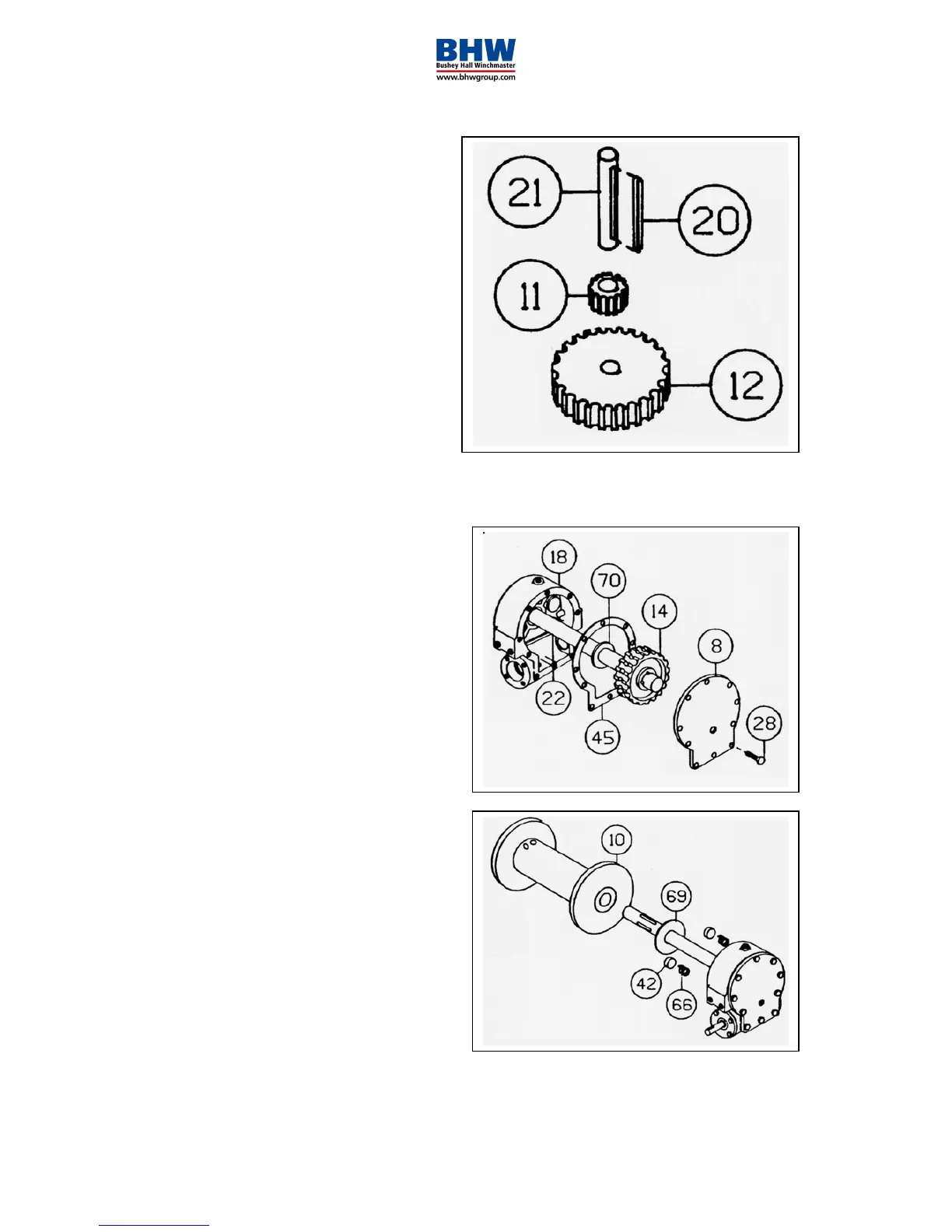

RE-ASSEMBLY

14. Apply grease to end of shaft, opposite

gear. Apply grease to bushing in gear

housing (item 18). Place greased end

of shaft through thrust washer (item

71) and bushing in gear housing (item

18). Place gasket (item 45) onto gear

housing cover (item 8). Apply grease to

gear end of shaft and bushing in cover.

Place cover onto shaft and secure to

housing with five (item 28) capscrews

at the five lower most holes.

15. Place winch, with gear housing cover

down, on work bench. Drum shaft

should be in vertical position. Slide

thrust washer (item 69) over drum

shaft and slide downwards until washer

rests on gear housing. Set springs

(item 66) and drag brake disc (item 42)

into pockets of gear housing. Grease

bushings in drum (item 10). Slide drum

assembly onto drum shaft with drum

jaws upward.

Loading...

Loading...