Page 12 of 37

INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

• Execute 4 holes with 12 mm diameter on the floor

by the holes on the bottom floor;

• insert the small blocks (excluded from supply) into

the holes;

• fix the machine to the ground with 4 M12x120 mm

screws (excluded from supply) (Fig. 5 ref. 1) (or

with 4 12x80 mm stud bolts (excluded from supply)).

Tighten the screws with an approximate tightening

torque of 70 Nm.

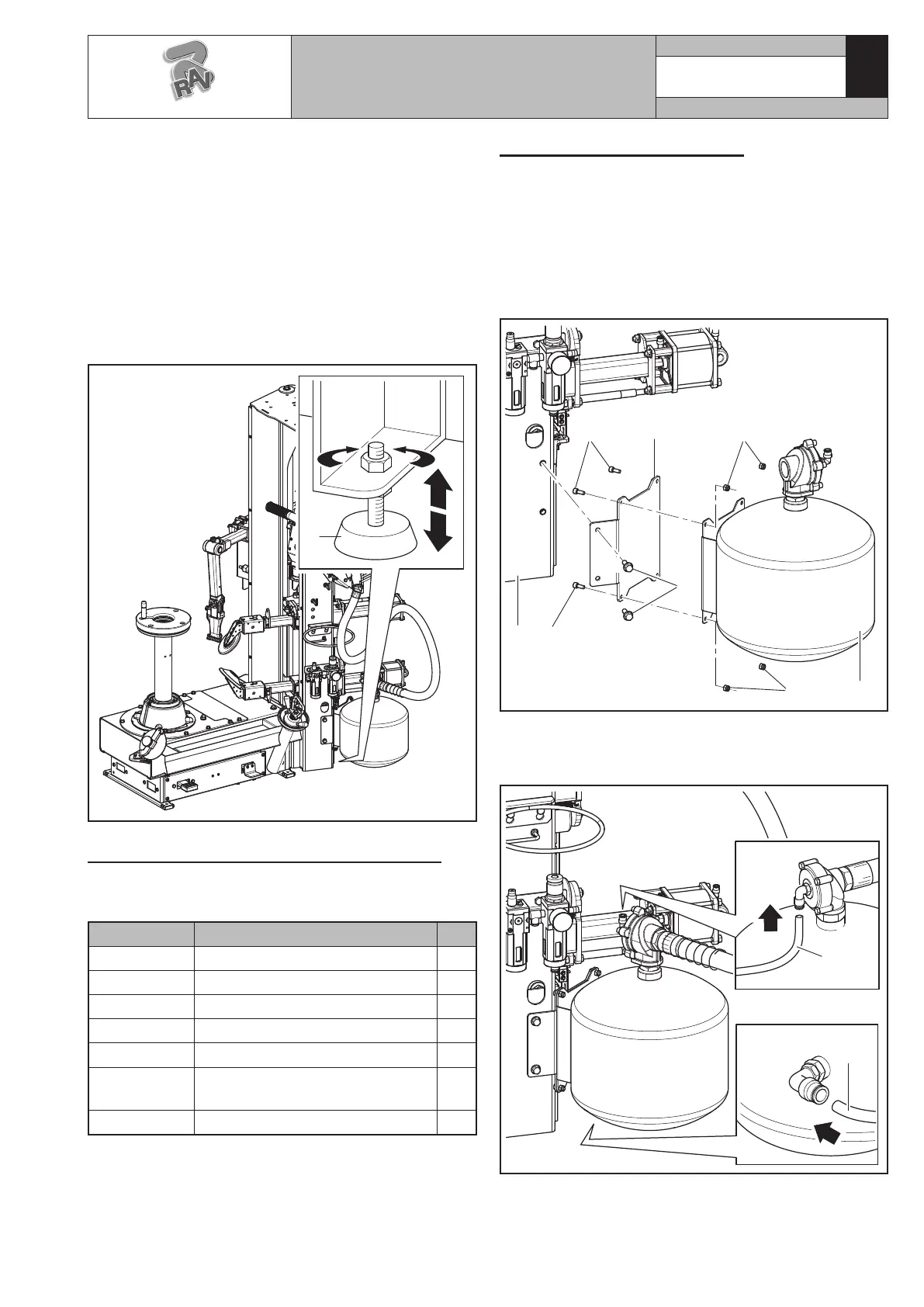

• Before clamping completely the machine to the floor,

level its rear part rotating the feet (Fig. 6 ref. 1).

1

Fig._6

9.2 Fixtures contained in the packing

The packing case contains also the fixtures box.

Check that all the parts listed are there.

Code Description N.

B1157000 Two-faced cone 1

710013421 Reverse wheels protection 1

710012941 Entrainer pin extension 1

710090481 Pin protection 1

790011620 Bead sliding foil 1

790011640

Instructions for bead sliding

foil

1

710590840 Bead insertion belt kit 1

9.3 Assembly procedures

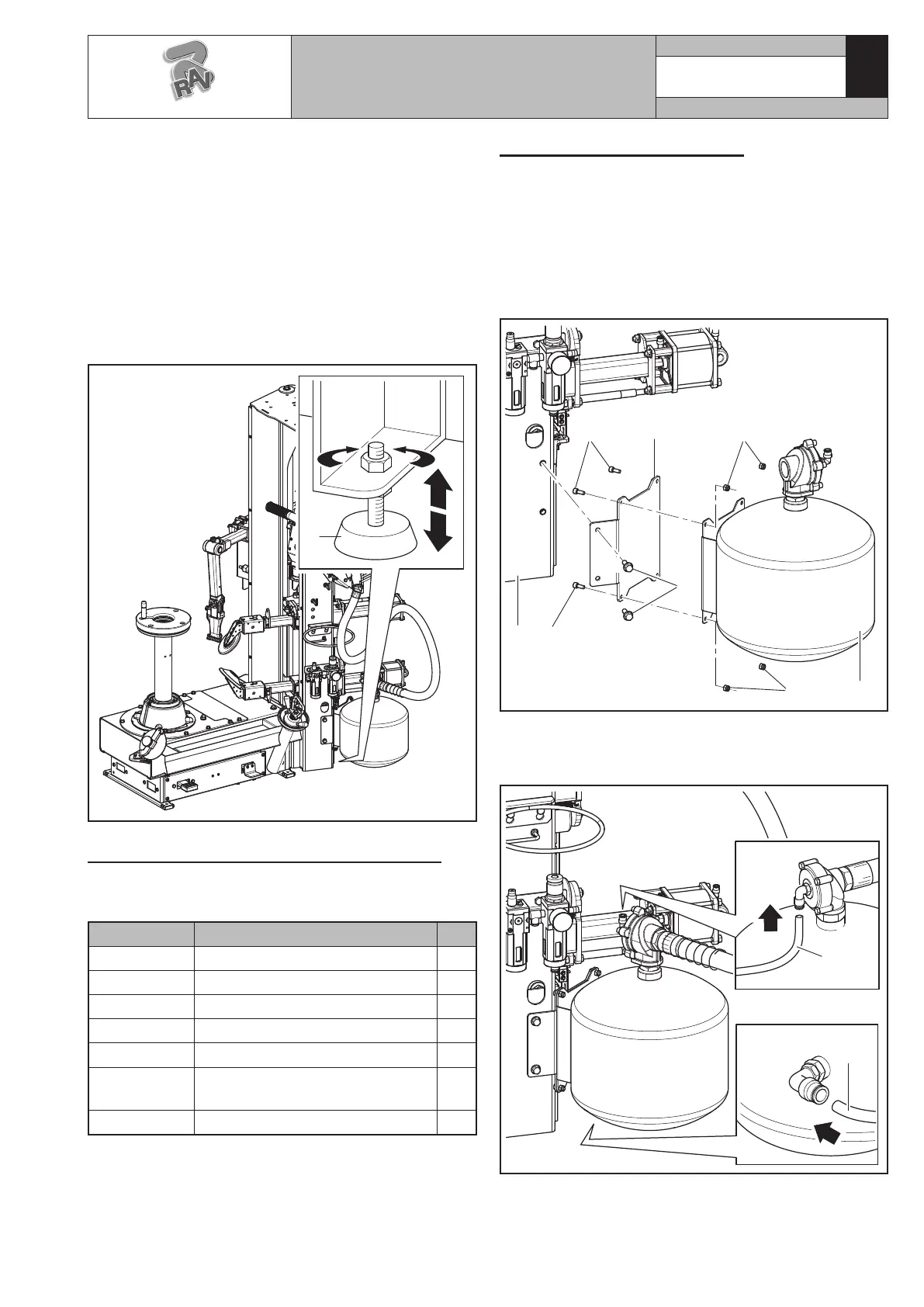

1. Assemble “Tubeless inflation” unit to the machine

keeping to the following instructions:

- fix the tank (Fig._7 ref._6) to the support flange

(Fig._7 ref._2) using the screws (Fig._7 ref._4)

and nuts (Fig._7 ref._5) equipped on issue;

- fix the flange (Fig._7 ref._2) to the machine (Fig._7

ref._3) using the screws (Fig._7 ref._1);

1

2

3

4

4

5

5 6

Fig._7

2. Connect the black pipe (Fig._8 ref._1) and the blue

pipe (Fig._8 ref._2) on the provided quick couplings

as shown in Figure 8.

1

2

Fig._8

3. Mount the grease bucket holder ring (# 0223000)

(Fig._9 ref._1), in the fixture box, using the 2 screws

provided (Fig._9 ref._2) to the machine body (Fig._9

ref._3).

G1180.30SLIM - G1180.30SLIMIT

7105-M002-10_R

RAVAGLIOLI S.p.A.

Loading...

Loading...